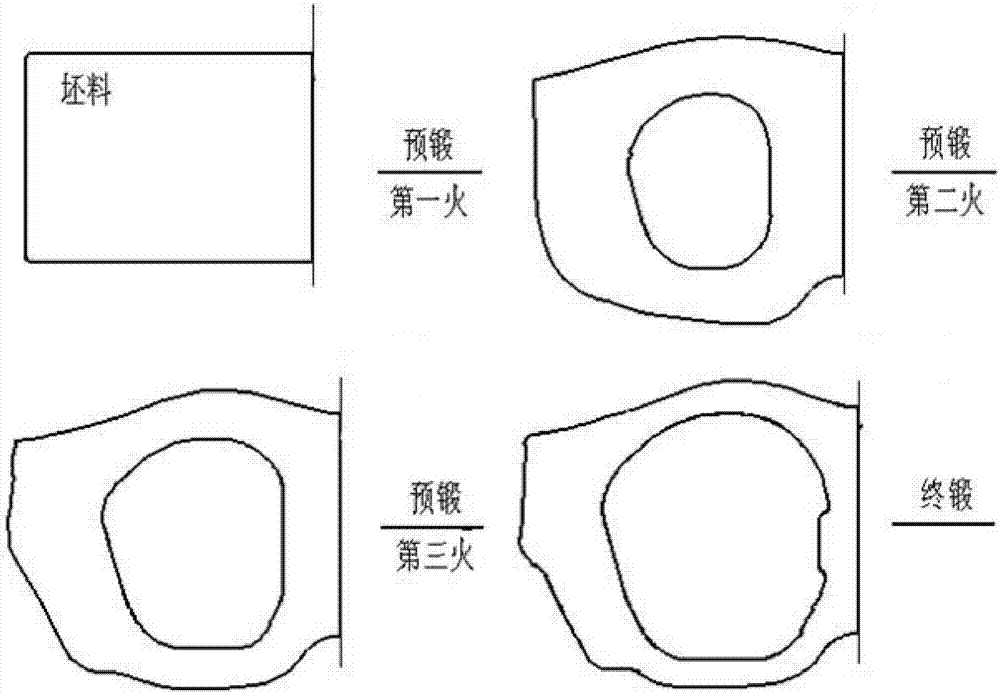

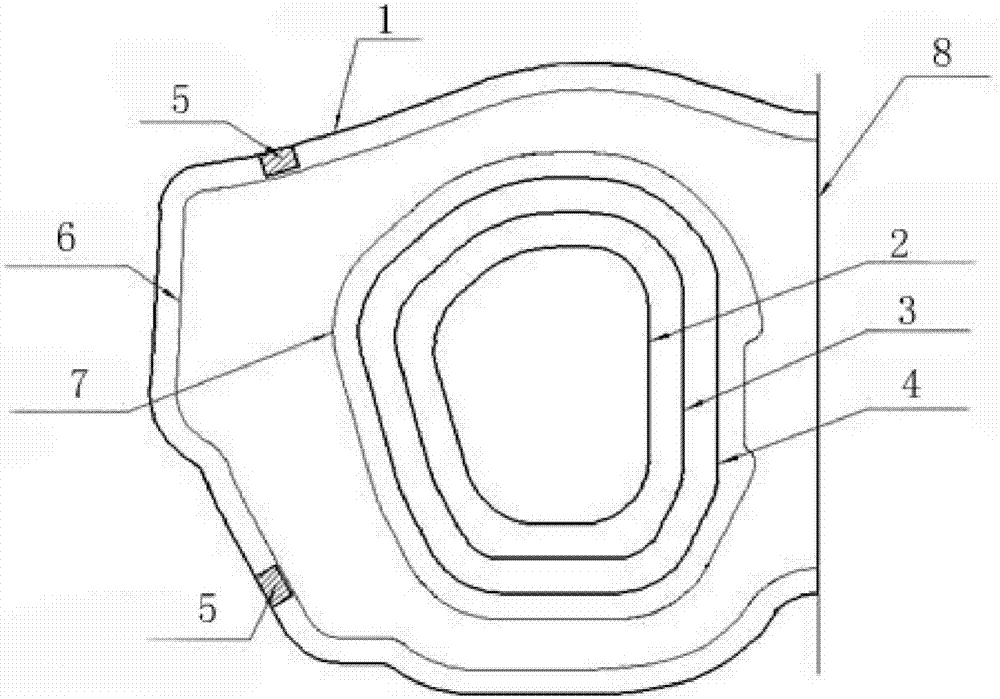

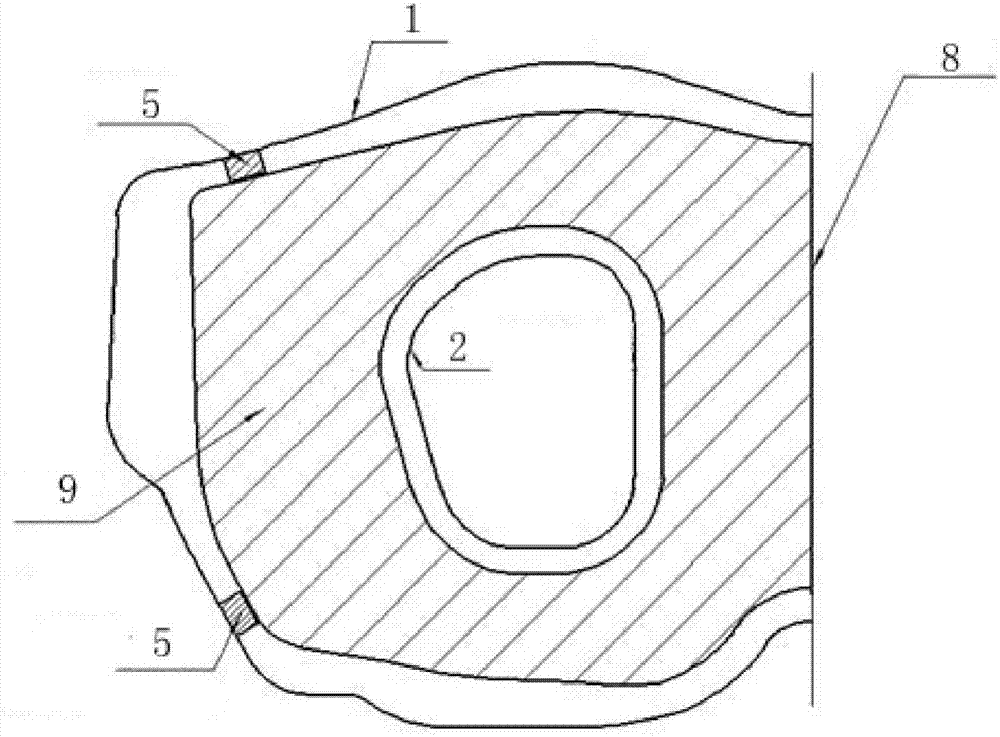

Hot wrapping process for hot forming of extra large titanium alloy whole frame die forging

A titanium alloy and hot forming technology, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of uneven structure and performance, poor filling of forgings, etc., achieve low cost, reduce equipment tonnage, The effect of good molding quality and uniformity of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific implementation.

[0036] Before the specific implementation of the hot sheathing process, it is necessary to conduct a hot sheathing process test to determine the sheathing material, specification, sheathing method, heating time after sheathing and the transfer time of the titanium alloy blank forging. The specific process is as follows:

[0037] a. Prepare several titanium alloy test blocks with the same specifications, and drill a temperature measuring hole directly to the center of the test block on the test block;

[0038] b. Preheat the titanium alloy test block, apply protective lubricant, and then self-heat and air-cool;

[0039] c. Place the titanium alloy test block in the heating furnace and heat it to the forging temperature. When the heating furnace reaches the temperature, heat preservation is carried out. The heat preservation time is calculated by multiplying the effective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com