Welding gun space position and posture self-adaptive adjustment system and method of wheel type welding robot

A welding robot, position and posture adaptive technology, applied in the direction of welding equipment, manipulator, welding rod characteristics, etc., can solve the problems of inability to track and adjust in real time, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with specific embodiments (not limited to this example) and with reference to the accompanying drawings:

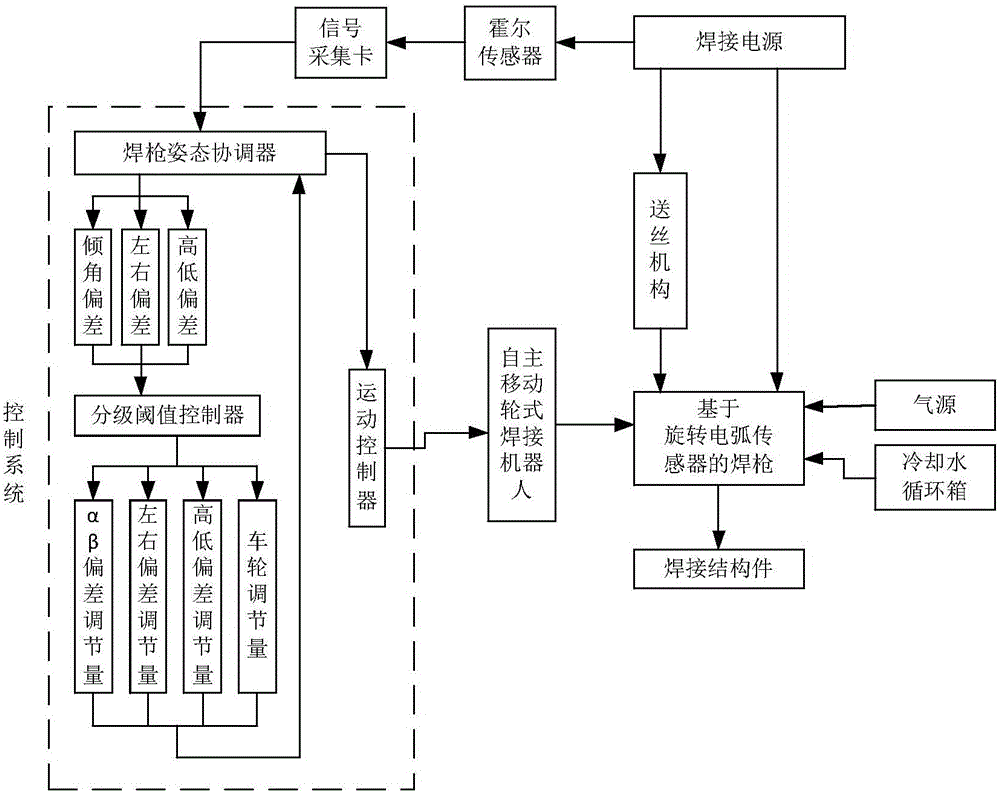

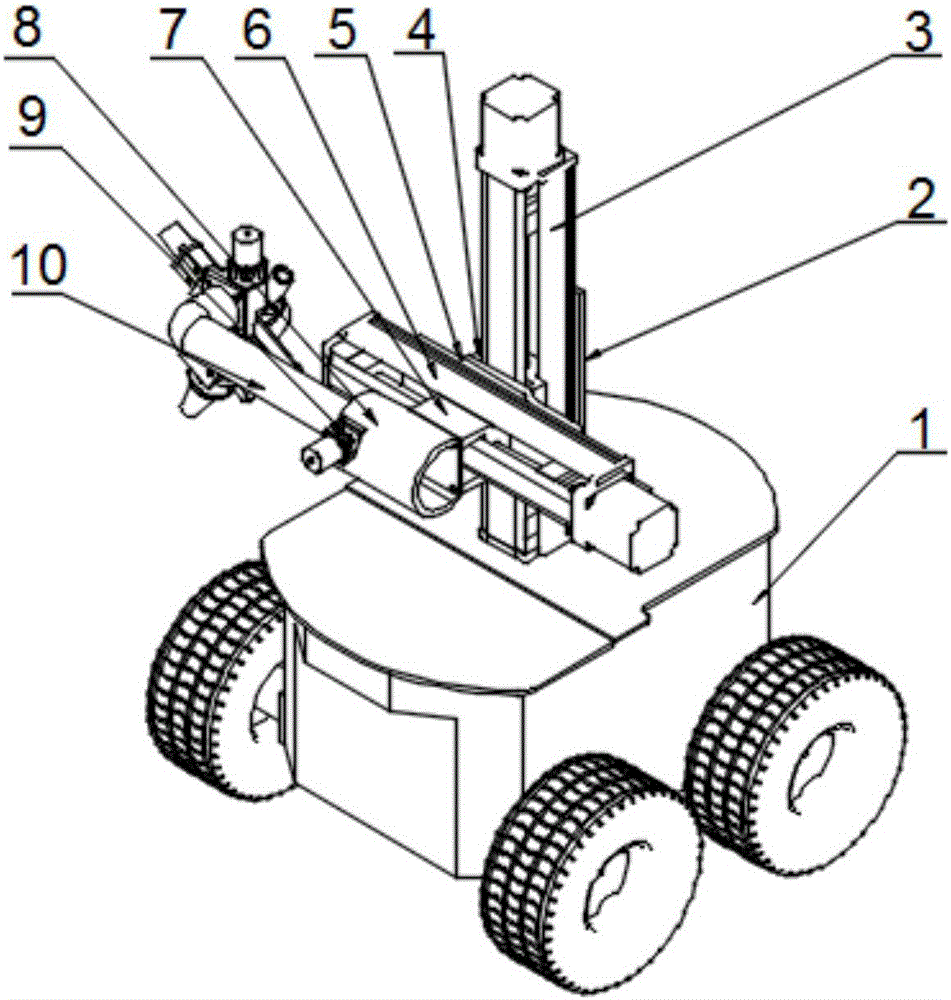

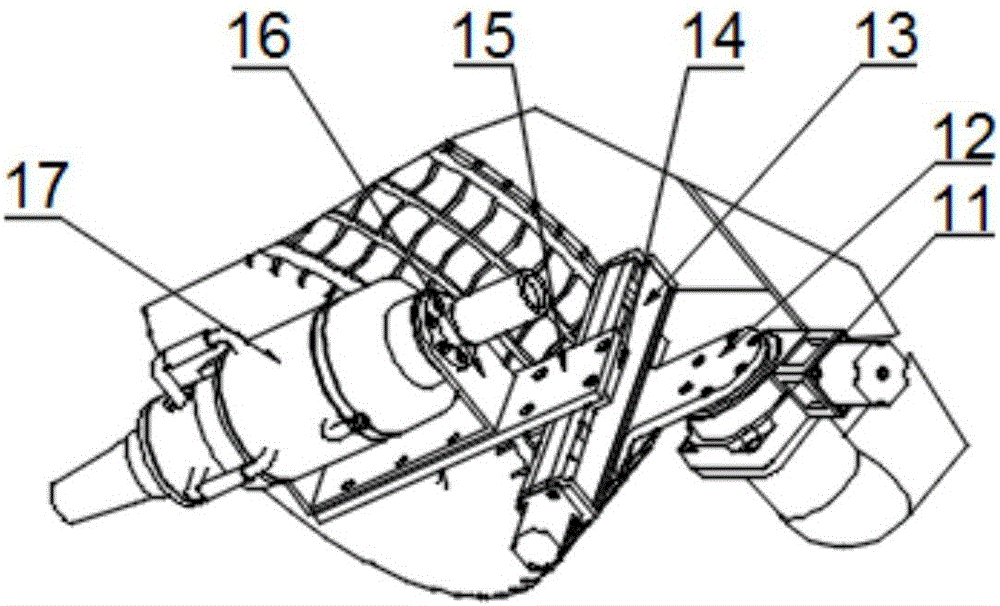

[0040] The basic idea of the present invention is to provide an adaptive real-time adjustment strategy for the space position and posture of the welding torch of an autonomously mobile wheeled welding robot based on a rotating arc sensor, as shown in the attached figure 2 And attached image 3 As shown, the schematic diagram of welding robot assembly. The vertical arm and horizontal arm installed on the roof plate of the Pioneer3DX self-moving trolley are fixedly connected to the α angle adjuster on the moving slider of the horizontal sliding arm, and the β angle adjuster is connected to the α angle adjuster through the hollow arm. The regulator is connected to the fine-tuning arm of the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com