Recombined decoration board and manufacturing method thereof

A technology for recombining decoration and boards, which is applied in household decoration, chemical instruments and methods, lamination devices, etc., to achieve significant ecological and social benefits, beautiful appearance, and the effect of saving natural and precious wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

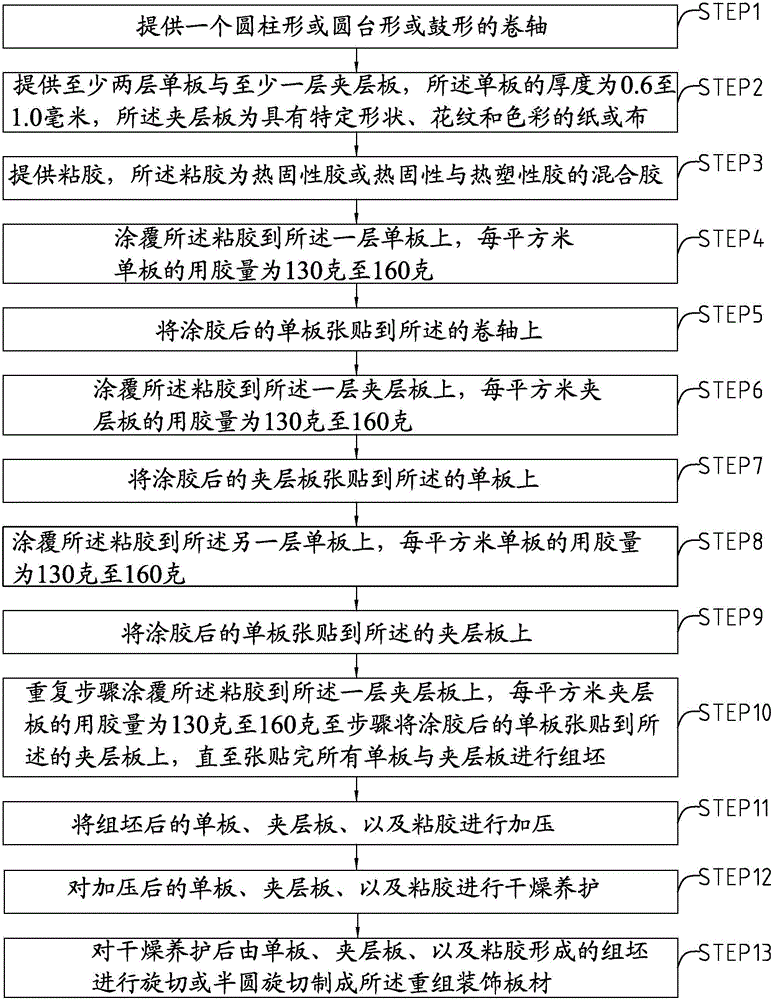

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

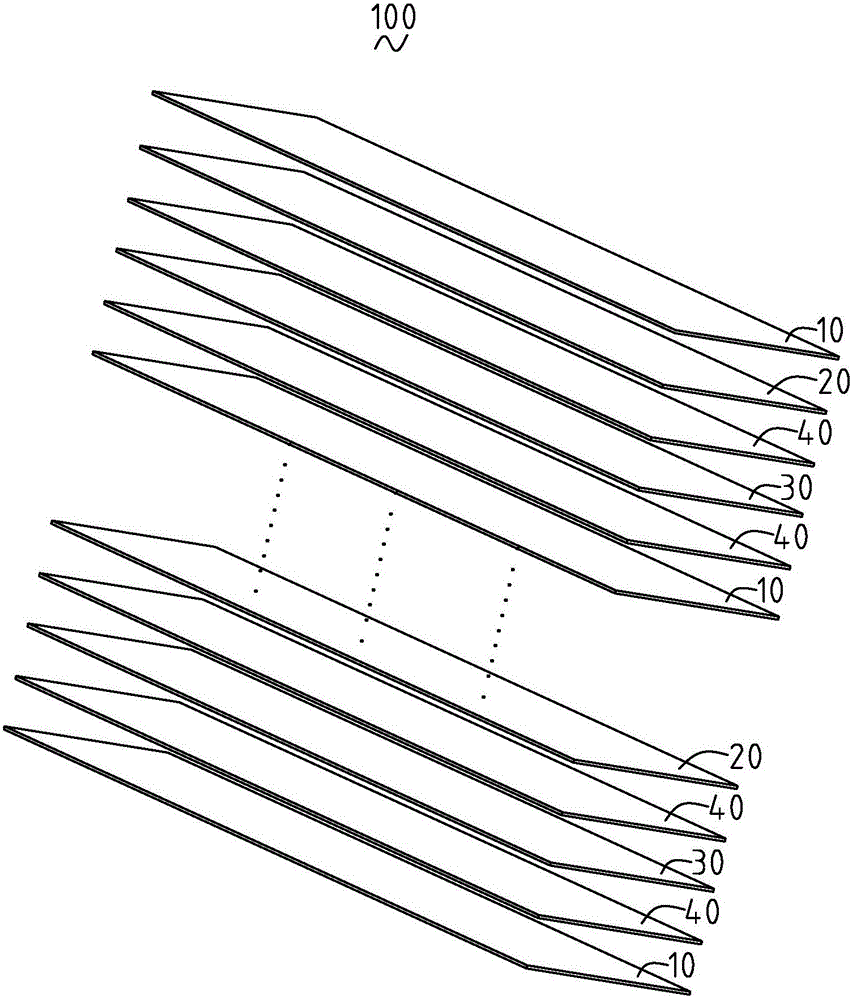

[0042] see figure 1 , which is a structural schematic diagram of a recombined decorative board 100 provided by the present invention. The recombined decorative board 100 includes at least two layers of veneers 10 arranged in sequence, at least one layer of interlayer boards 20 sandwiched between each two layers of adjacent veneers, and at least one layer of sandwiched veneers 20 between the veneers 10 and the sandwich panel 20 or the plastic film 30 between the veneer 10 and the veneer 10 , and the glue 40 for bonding the veneer 10 , the sandwich panel 20 and the plastic film 30 .

[0043] The veneer 10 can be made of ordinary tree species or artificial forest logs such as poplar w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com