High-ink load offset print coating resin plate

A resin plate, printing and coating technology, applied in printing plate, printing, printing foil, etc., can solve the problems of difficult plate making and machine adjustment, poor printing leveling, printing precision is not good enough, etc., to achieve the elimination of fineness Insufficient, improve the ink loading capacity, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

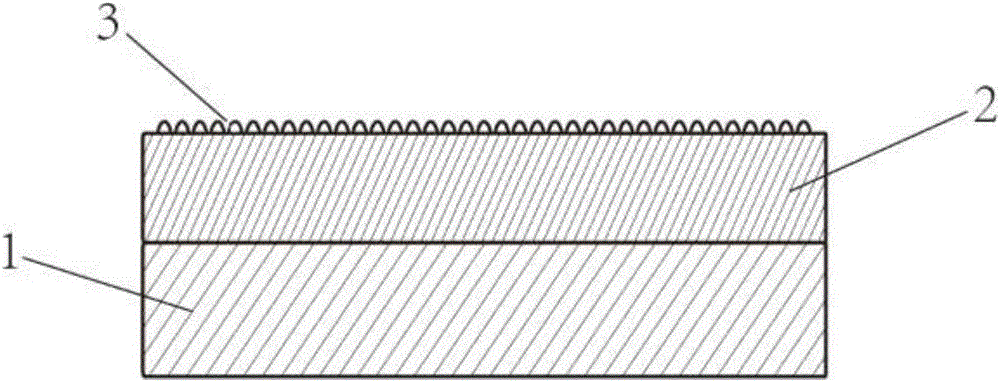

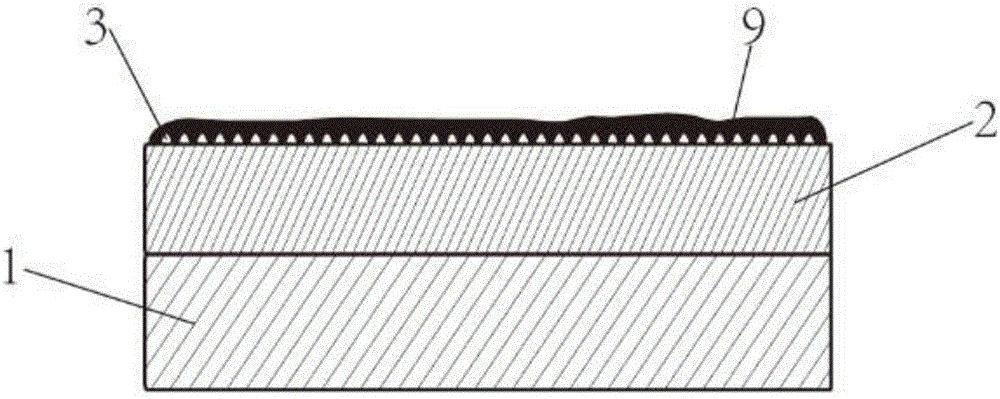

[0032] Figure 1-2 The offset coated resin plate with high ink loading shown includes a resin plate substrate 1 and a photosensitive layer 2; the surface of the photosensitive layer 2 is provided with a number of groove-like structures arranged in a certain form.

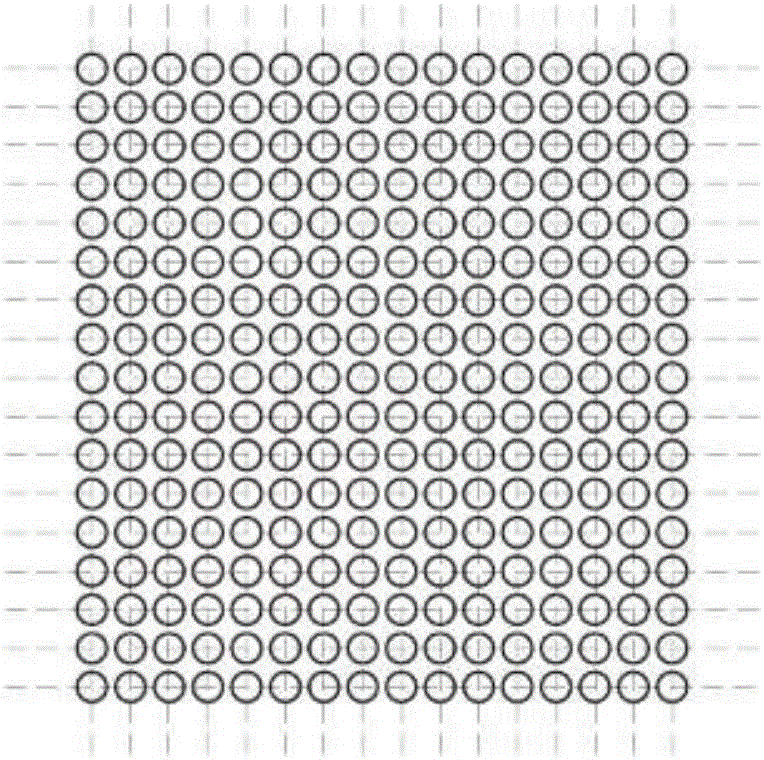

[0033] Wherein, the groove structure is a dotted groove 3 . The diameter of the dotted grooves 3 is 0.1 mm, the depth is 0.03-0.05 mm, and the distance between the dotted grooves 3 is 0.03 mm. The dotted grooves 3 can be arranged in a "well" shape, such as image 3 As shown, it can also be arranged in a "honeycomb" shape, such as Figure 4 As shown, it is obvious that other arrays or irregular arrangements can also be used.

Embodiment 2

[0035] Figure 5-7 The offset coated resin plate with high ink loading shown includes a resin plate substrate 1 and a photosensitive layer 2; the surface of the photosensitive layer 2 is provided with a number of groove-like structures arranged in a certain form.

[0036] Wherein, the groove-shaped structure is a strip-shaped groove 8 and is linear, and the cross-section of the strip-shaped groove is trapezoidal, with a top width of 0.2-2.6mm and a bottom width of 0.6-3.0mm. The slot pitch is 0.2 mm. Apparently, the cross-section can also be arc-shaped or other suitable shapes, and the strip-shaped grooves can also be circular or polygonal, and the strip-shaped grooves can be arranged at equal or unequal intervals.

Embodiment 3

[0038] Figure 8 The offset coating resin plate with high ink loading shown, wherein, the groove-like structure is a strip groove and is a quadrilateral, obviously also can be a triangular ( Figure 9 shown), pentagonal or hexagonal ( Figure 10 shown), etc. The rest are basically the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com