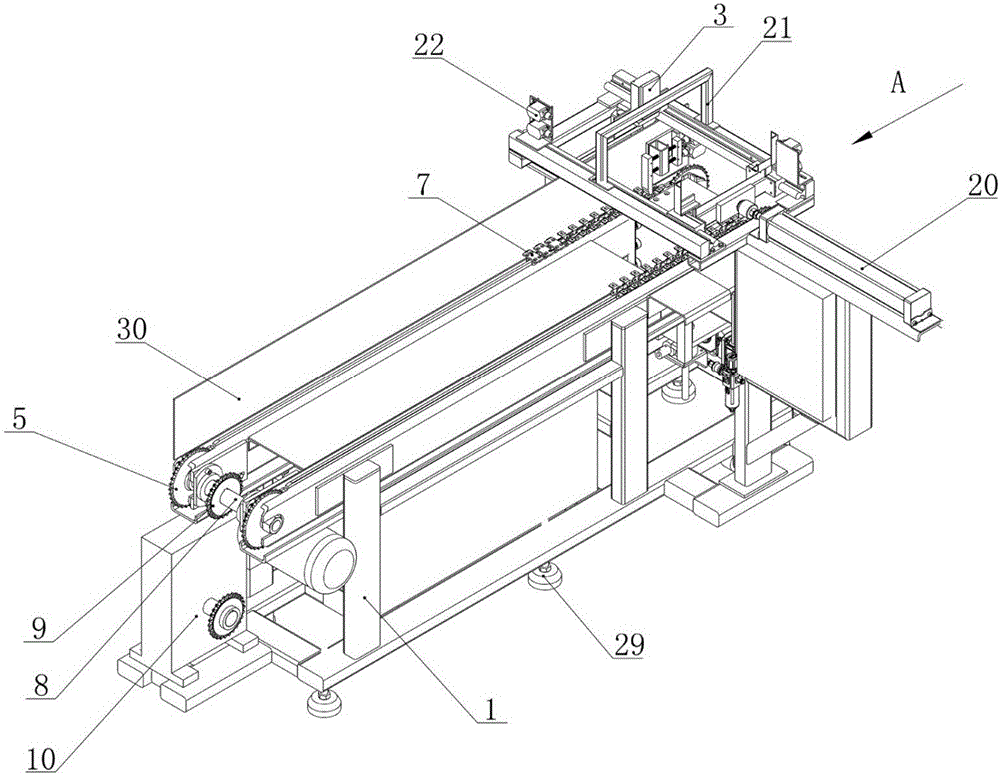

Automatic smelting furnace charging device

A feeding device and furnace technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of long metal blank feeding intervals, difficult feeding, low production efficiency, etc., to promote sustainable development, reduce production costs, structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The present invention will be further described in detail below with reference to specific embodiments and drawings, but the present invention is not limited to these embodiments.

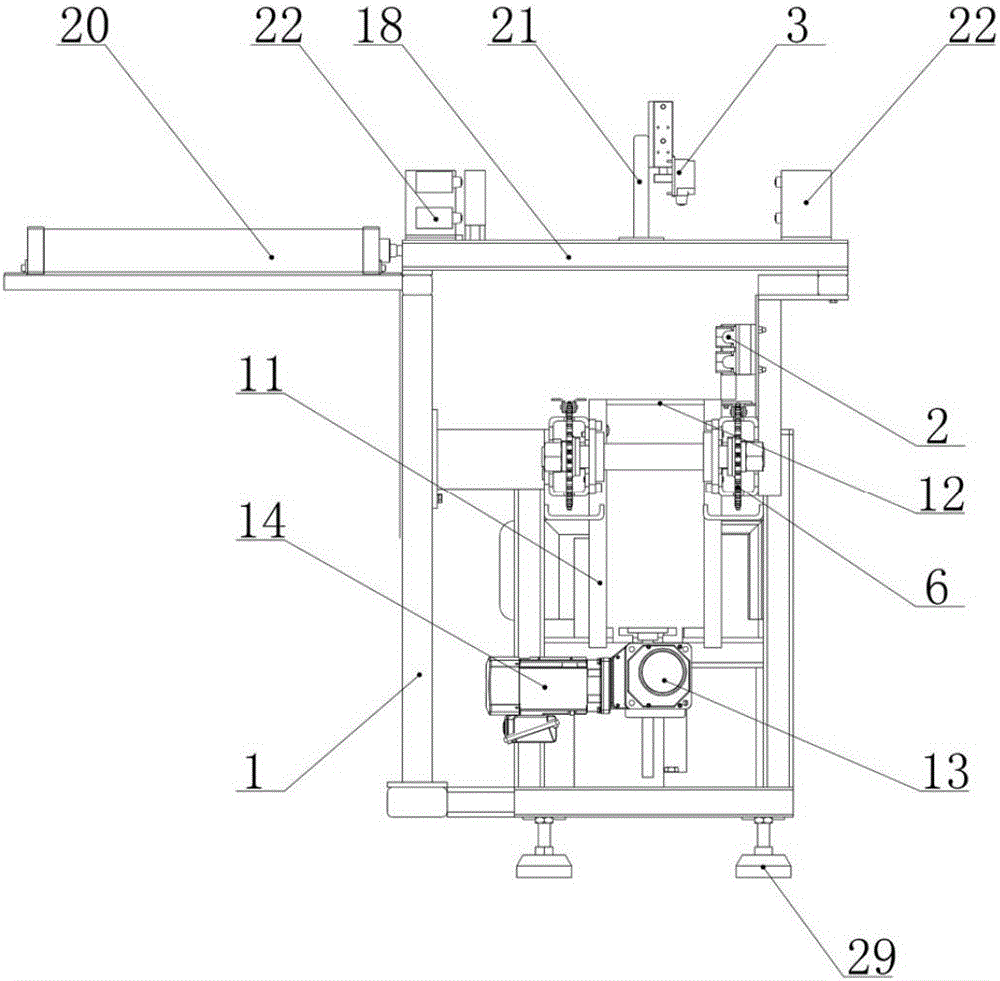

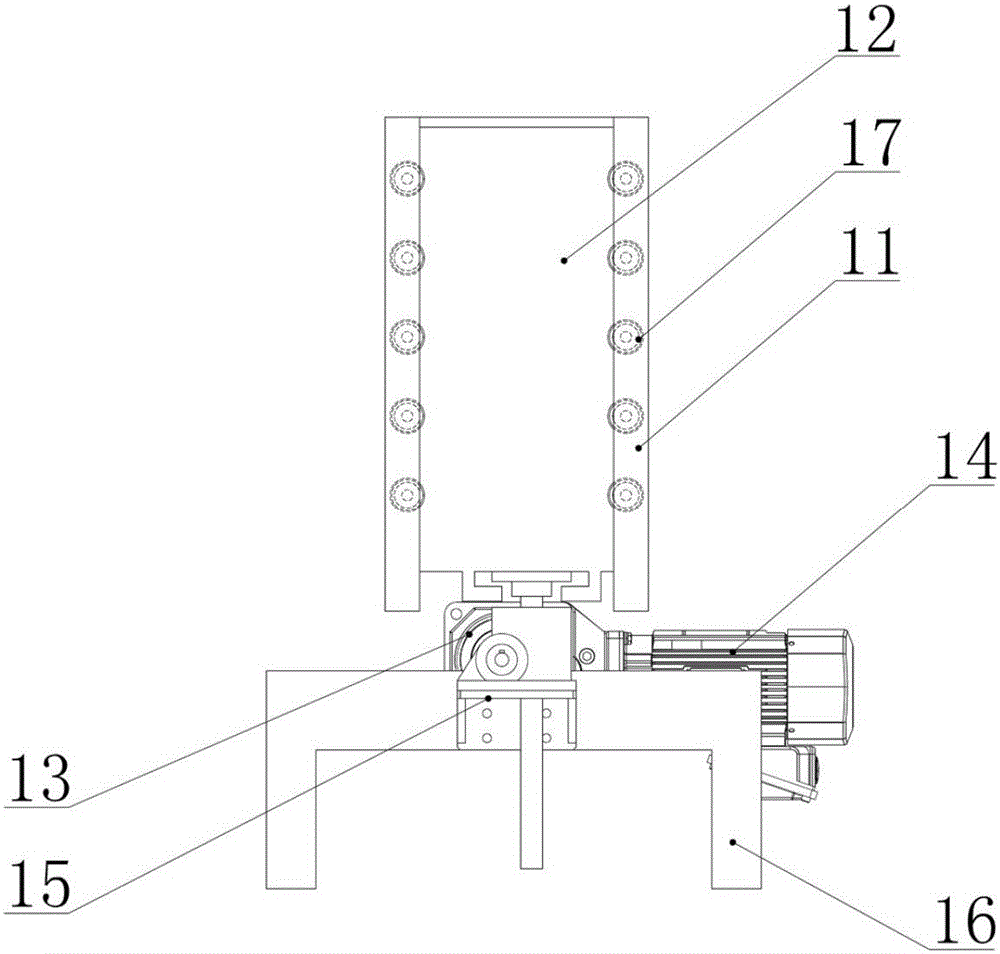

[0024] See Figure 1-Figure 5 , The present invention is an automatic furnace charging device, including a frame 1, at the bottom of the frame 1 is provided with walking rollers (not shown in the figure) and adjustable lifting feet 29, easy to move and positioning support; horizontally arranged on the frame There is a horizontal conveying and feeding mechanism for conveying stacked blanks 31, a jacking mechanism is arranged at the lower part of the feeding end of the horizontal conveying and feeding mechanism, and a pushing mechanism is arranged longitudinally at the upper part of the feeding end of the horizontal conveying and feeding mechanism, and push The feeding mechanism and the jacking mechanism are set up and down correspondingly. In order to ensure that the stacked blanks on the horizo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap