Steel coil lifting device automatic identification device and method adopting machine vision

An automatic identification and machine vision technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of low operation efficiency and low operation accuracy of the steel coil grasping system, and achieve improved production efficiency, low requirements, and low operation. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

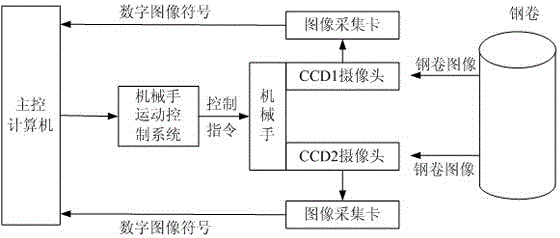

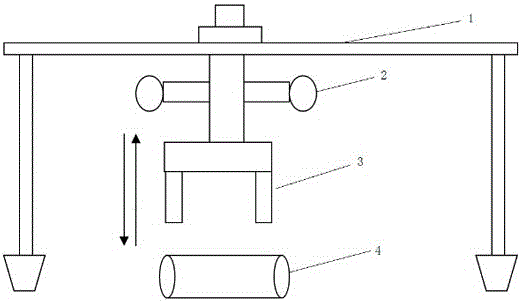

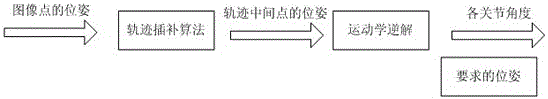

[0038] Such as figure 1 and figure 2 As shown, an automatic identification device for steel coil cranes using machine vision includes a manipulator and two CCD cameras mounted on the manipulator. The CCD camera is connected to the main control computer through an image acquisition card, and the manipulator motion control system is installed on the main control computer. , the manipulator motion control system controls the manipulator to move accordingly through control instructions. The motion control system of the manipulator includes a motion controller for planning and monitoring the motion trajectory of the manipulator and a servo driver connected to the motion controller for driving each motor based on the motion trajectory of the manipulator so that the manipulator Exercise accordingly. A guide rail is provided on the manipulator, and a fixing device is provided between the guide rail and the manipulator, and the CCD camera can freely slide laterally on the guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com