Double-sided sueding machine

A sanding machine and double-sided technology, which is applied in the direction of fabric surface trimming, textile and paper making, and roughening, etc., can solve the problems of long cloth running route, prone to curling, straight strips, and difficult control of the tension of the cloth guide roller, etc. Achieve rapid separation and improve control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

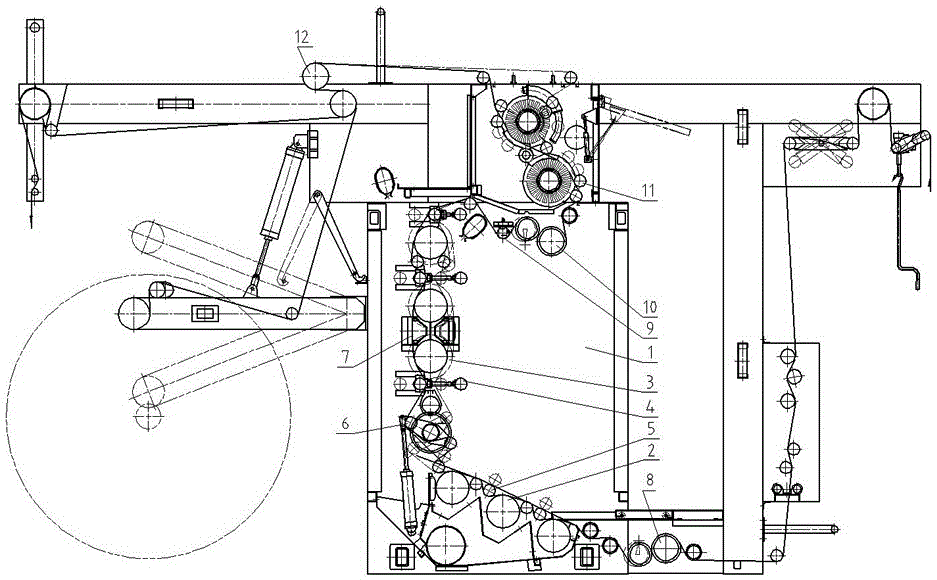

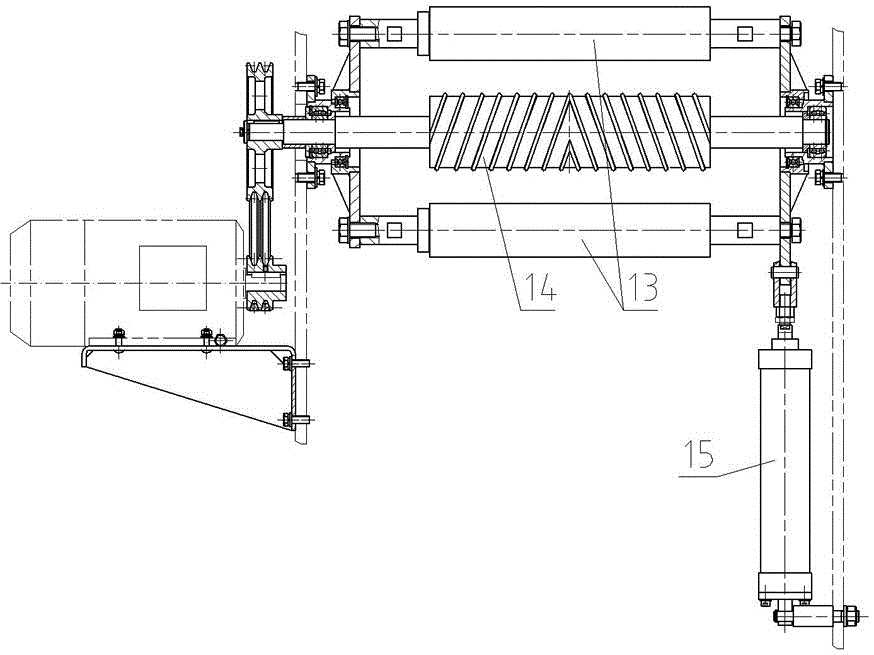

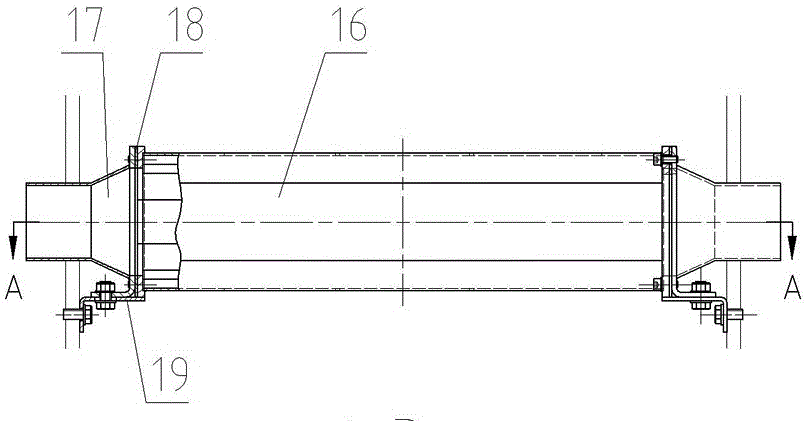

[0022] as attached figure 1 As shown, a double-sided sanding machine includes a frame 1, a rigid sanding roller 2, and a flexible sanding brush roller 3, including three groups of front, middle and rear sanding rollers, and the front part is a group of oblique Three rigid sanding rollers 2 are set, the middle part is a group of three rigid sanding rollers 2 vertically arranged vertically or a flexible brush roller 3, and the rear part is a group of two flexible brush rollers 3 ; The front and middle two groups of sanding rollers are provided with a swinging single and double-sided sanding route replacement device 6 (such as figure 2 shown), the swing-type single- and double-sided sanding route replacement device 6 includes a swing roller 13, an expansion roller 14, and a driving cylinder 15; The tension detection device 9 in the sanding area and the rubber roller type middle cloth guide roller 10; the front, middle and rear three groups of sanding rollers are respectively m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com