Suspension type monorail vehicle turnout system

A suspended, monorail technology, applied in the field of cargo transportation, can solve a large number of container truck traffic pressure, pollution, container truck exhaust emission environment and other problems, to achieve the effect of fully automatic operation and solve traffic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

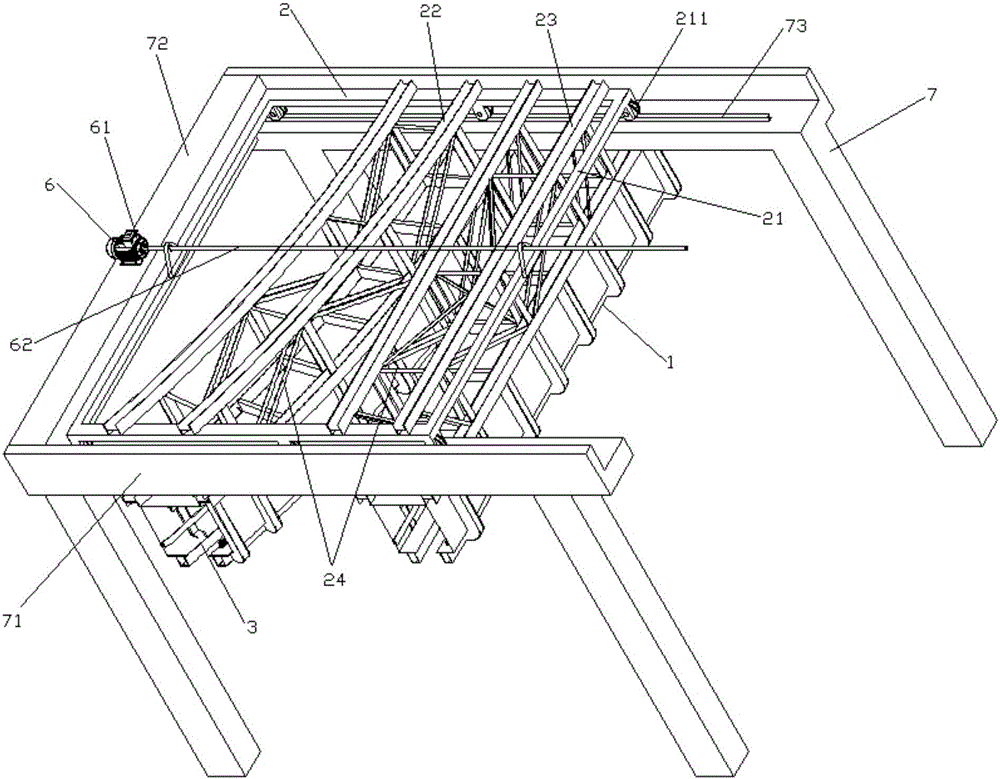

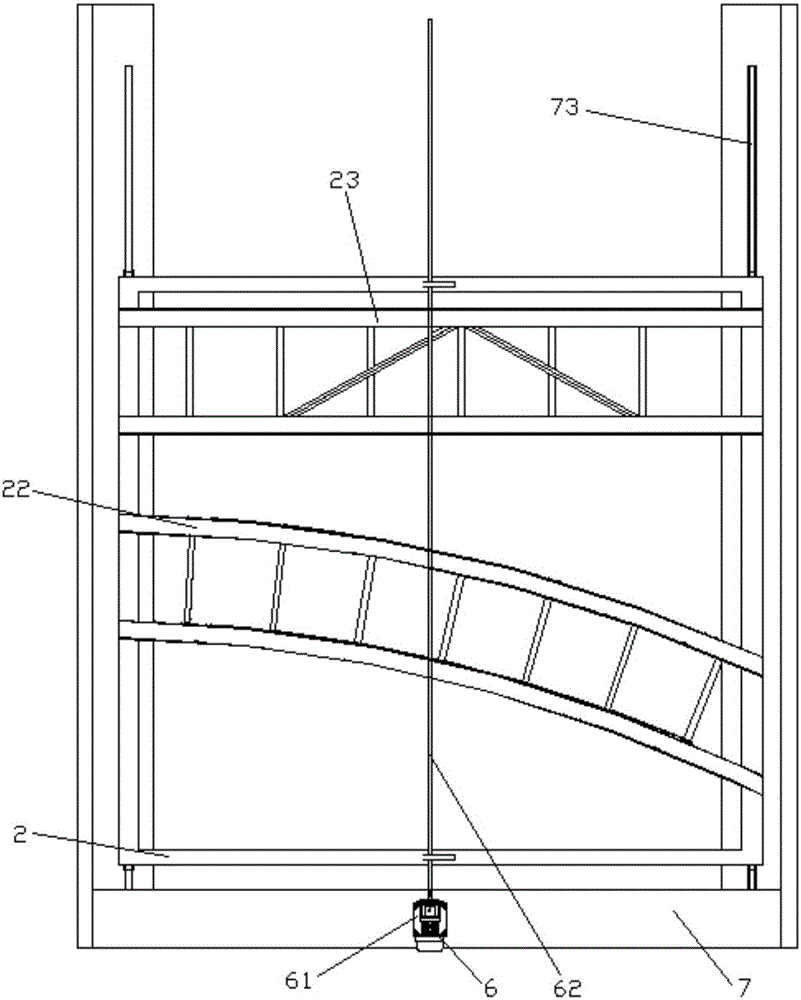

[0020] The embodiment of the present application provides a suspended monorail vehicle turnout system, which can not only realize the fully automated operation of the terminal, but also solve the traffic pressure caused by a large number of container trucks and the exhaust emission of a large number of container trucks when transferring containers to other container logistics centers The technical problems of environmental pollution brought about.

[0021] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

[0022] A suspended monorail vehicle turnout system, the suspended monorail vehicle turnout system includes: a bracket; a suspension, movably arranged on the bracket; a driving device, fixed on the bracket, for driving the suspension The frame moves on the support; the linear guide rail and the arc guide rail are suspended on the suspension and can move relative to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com