Pole pit tamping device for electric power engineering construction

A technology of electric power engineering and compaction device, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of bulky compaction machinery, inconvenient use, inflexible movement, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

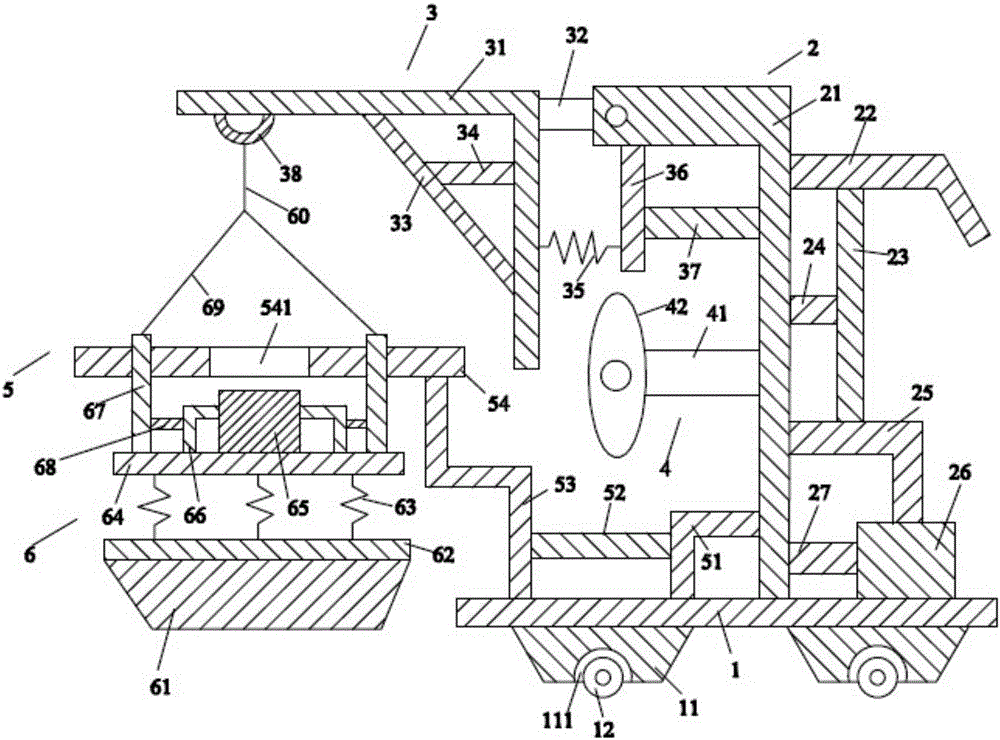

[0019] like figure 1 As shown, the rod hole tamping device for electric power engineering construction of the present invention includes a base plate 1, a support device 2 above the base plate 1, a rotation device 3 on the left side of the support device 2, and a cam located below the rotation device 3. Device 4 , a positioning device 5 located below the cam device 4 , a hammer device 6 located below the rotating device 3 .

[0020] like figure 1 As shown, the bottom plate 1 is rectangular parallelepiped and placed horizontally, and the bottom plate 1 is provided with first support blocks 11 on the left and right sides below it and first rollers 12 below the first support block 11 . There are two first support blocks 11, the cross section of the first support block 11 is isosceles trapezoidal, the upper surface of the first support block 11 is fixedly connected with the lower surface of the bottom plate 1, the The lower surface of the first supporting block 11 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com