Unilateral supporting formwork basement outer wall with flexible waterproof layer outer formwork

A basement exterior wall, flexible waterproof technology, applied in basic structure engineering, building components, excavation and other directions, can solve problems such as unfavorable civilized construction and site management, loose control of construction time, damage to waterproof layer, etc. Civilized management, avoiding post-construction deformation and uneven settlement, and avoiding the effect of long-term exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

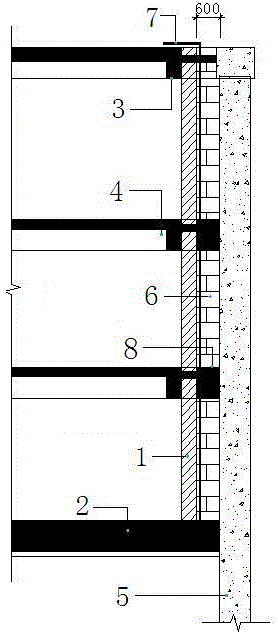

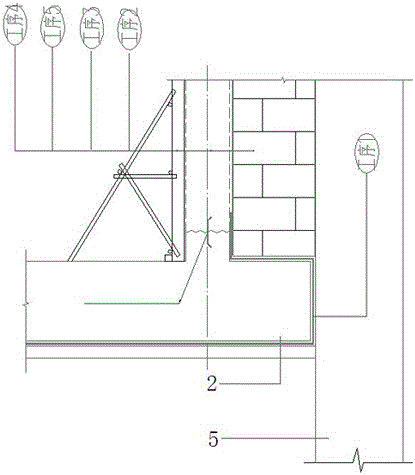

[0037] Such as figure 1 As shown, a basement exterior wall with a single-side formwork with a flexible waterproof layer outer mold, which includes a basement exterior wall 1, the bottom of the basement exterior wall 1 is provided with a waterproof bottom plate 2, and integrated inner supports are respectively provided on both sides Side beams 3 and rigid support piles 5, there is a gap between the rigid support piles 5 and the basement outdoor wall 1, and a filling wall 6 composed of filling blocks is filled in the gap, and the filling wall 6 and the basement outdoor A flexible waterproof layer 7 is arranged between the walls 1 .

[0038] In this waterproof structure, the waterproof bottom plate 2 is turned up and pasted on the bottom of the basement exterior wall 1 . The flexible waterproof layer 7 is composed of waterproof coiled material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com