Workshop stand column embedded iron structure

A technology of pre-embedded iron and columns, which is applied to building construction, on-site preparation of building components, formwork/formwork/work frame, etc., which can solve inaccurate positioning of pre-embedded iron, large amount of pre-embedded iron, and cumbersome construction To achieve the effect of reducing the construction period and construction waste, increasing the compressive strength, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

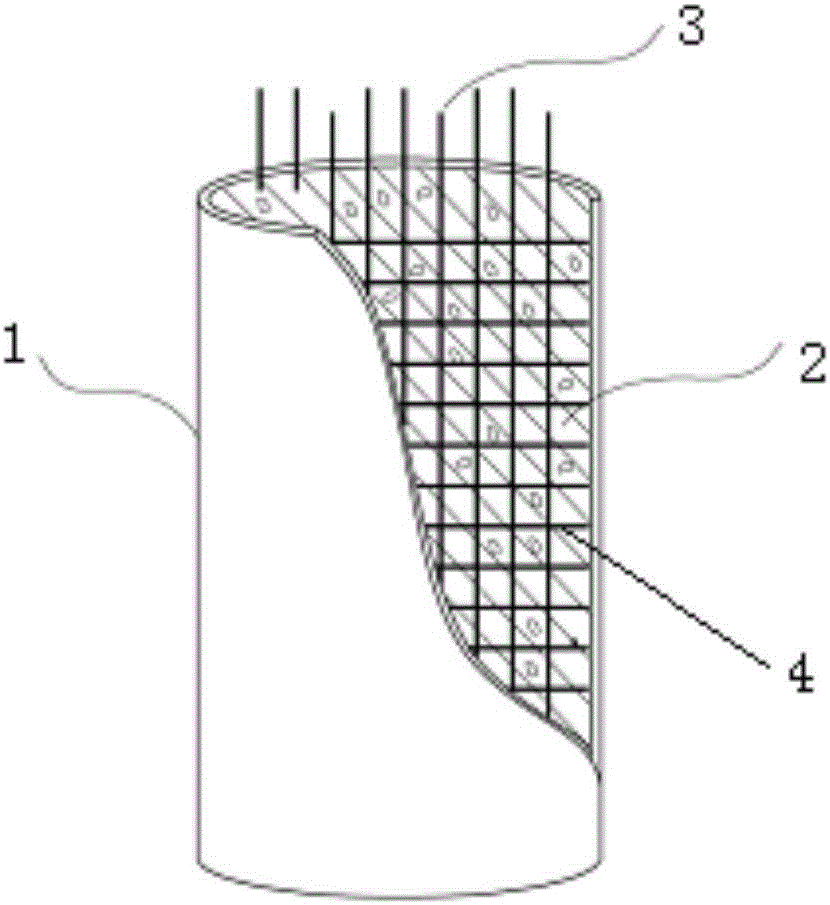

[0012] The present invention will be further explained below in conjunction with the drawings.

[0013] Such as figure 1 Shown is the structure diagram of the present invention, including: a steel pipe 1, a number of steel bars 3 extending along the length of the steel pipe 1 and reinforcing ribs 4 perpendicular to the steel bar 3 are evenly distributed in the internal cavity of the steel pipe 1. A columnar steel bar network with a size matching the internal cavity of the steel pipe 1 is formed; the columnar steel bar network is filled with concrete 2 in the void formed in the steel pipe 1.

[0014] The steel pipe 1 is used as both the template of the column and the embedded iron of the column. When it is suitable for multi-layer structure workshops, the steel pipes between two adjacent layers can be connected by welding or by flange structure, using flange connection At least one end of the two ends of the steel pipe 1 is provided with a flange cover, and the steel pipe 1 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com