Post-earthquake rapid repair of precast concrete column feet and its construction and maintenance methods

A prefabricated concrete and concrete technology, applied in the direction of columns, pillars, pier columns, etc., can solve the problems of poor stress distribution at the joints, unsatisfactory seismic performance, and lack of quick repairs, etc., to achieve easy implementation of construction quality control and reduce earthquake response , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

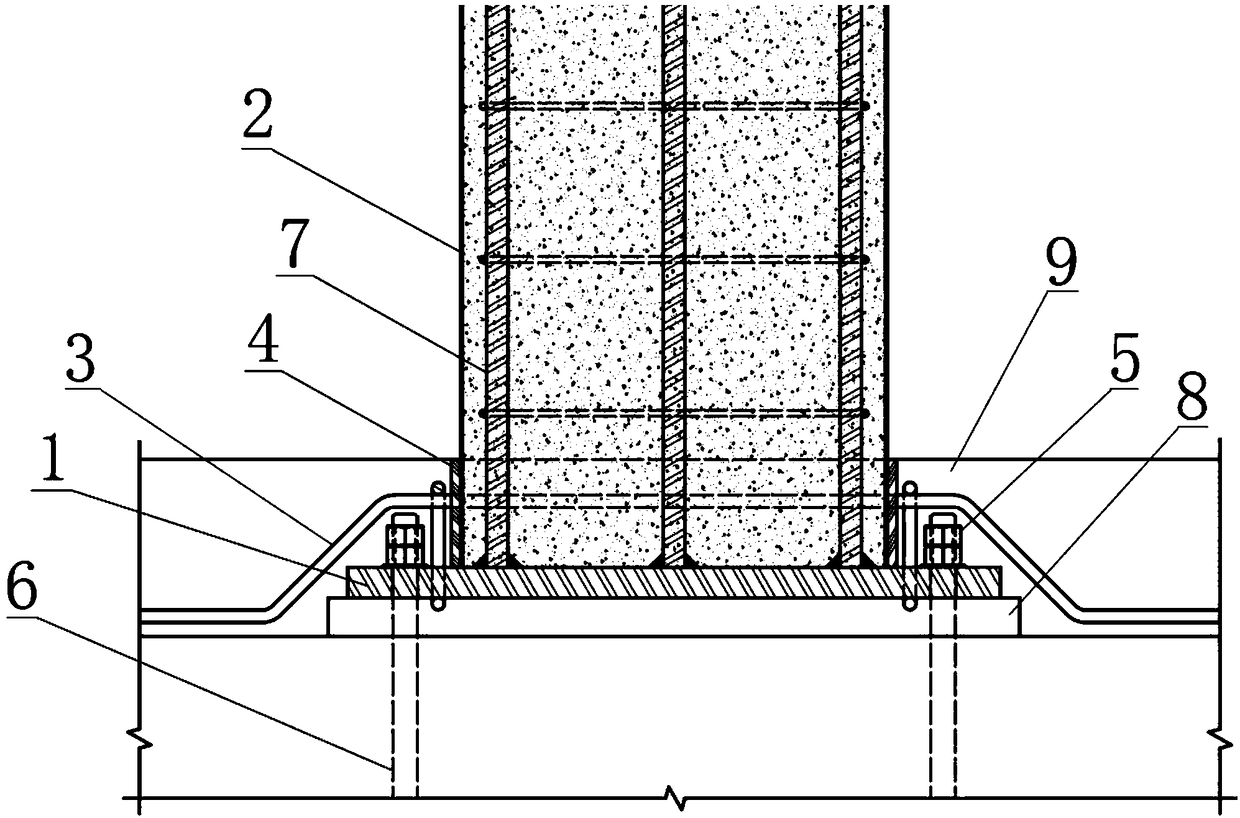

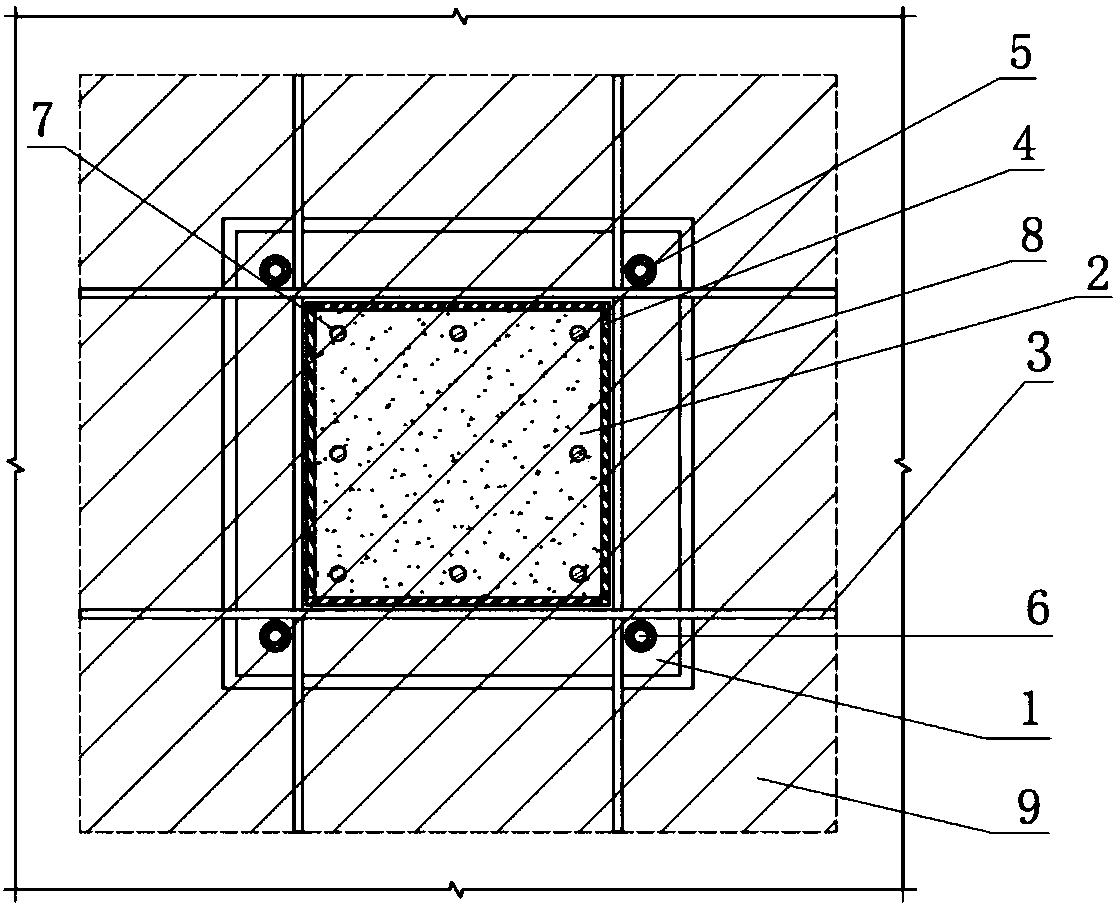

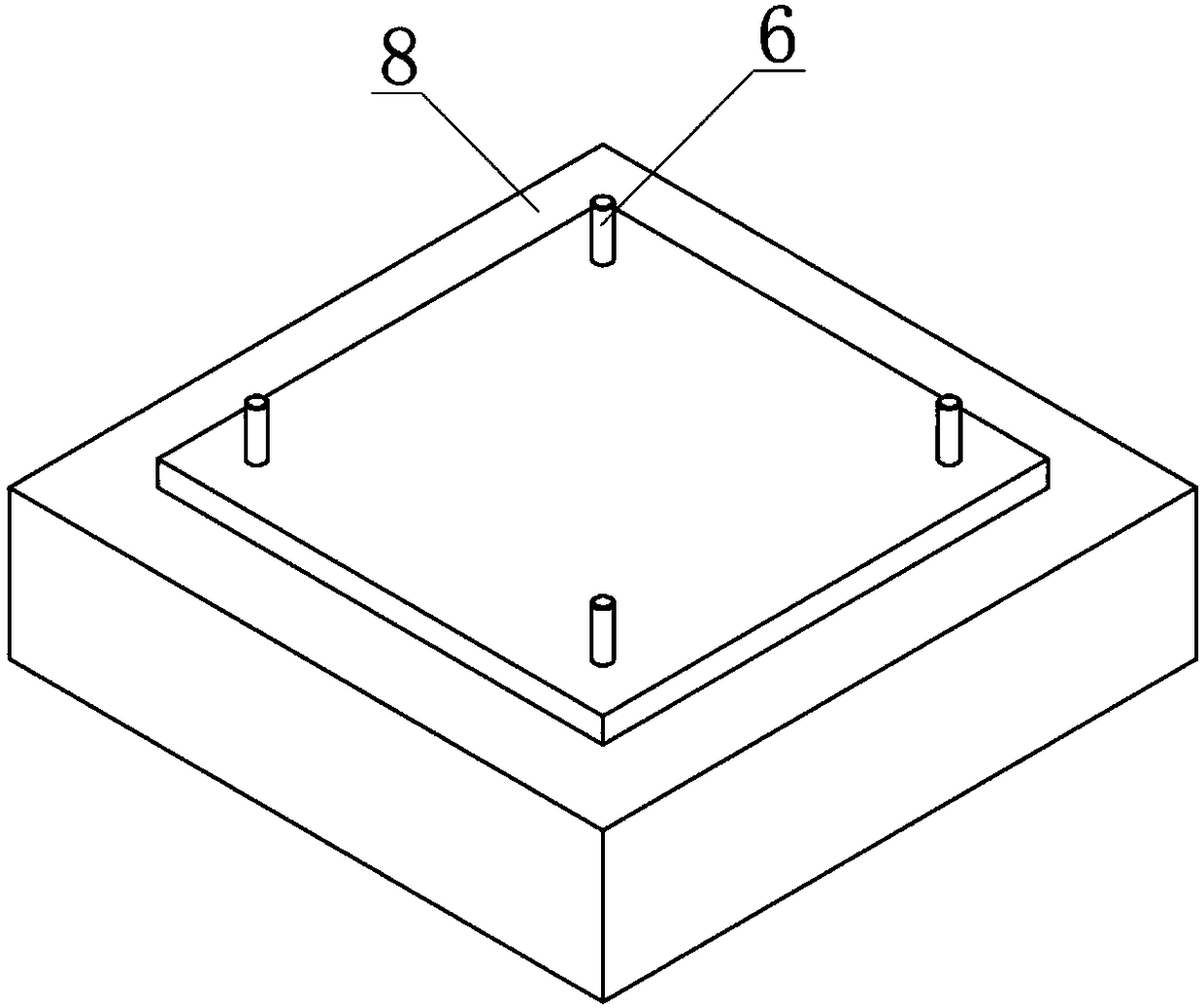

[0028] Such as figure 1 , figure 2 The post-earthquake rapid repair prefabricated concrete column foot is shown, including a steel base plate 1 with openings, a precast concrete column body 2, a well-shaped reinforced steel bar 3, a foundation mortar layer 8, a rubber cushion 4 and a post-cast bottom layer Floor 9, anchor bolts 6 pass through the openings of the steel floor 1 to fix the steel floor 1 on the foundation mortar layer 8; type arrangement, the anchor head of the anchor bolt 6 is a screw and is equipped with a high-strength nut 5. The steel bottom plate 1 with openings is welded to the longitudinal reinforcement 7 of the precast concrete column body 2 . The rubber pad 4 is tightly fitted around the bottom of the precast concrete column 2, and the top is higher than the top of the well-tac-toe reinforced steel bar 3 and the anchor bolt 6, and is flush with the top of the poured bottom floor 9. The steel bottom plate 1 is provided with several centrally symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com