An anti-collision steel plate wrapping column system

A steel plate and column-wrapped technology, which is applied in the field of anti-collision steel plate-wrapped column system, can solve the problems affecting the safety and beauty of the factory building structure, difficult to achieve coordination and unity, and the concrete structure column is damaged, so as to increase the compactness and improve the construction operation. Easy to solve frequently damaged effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

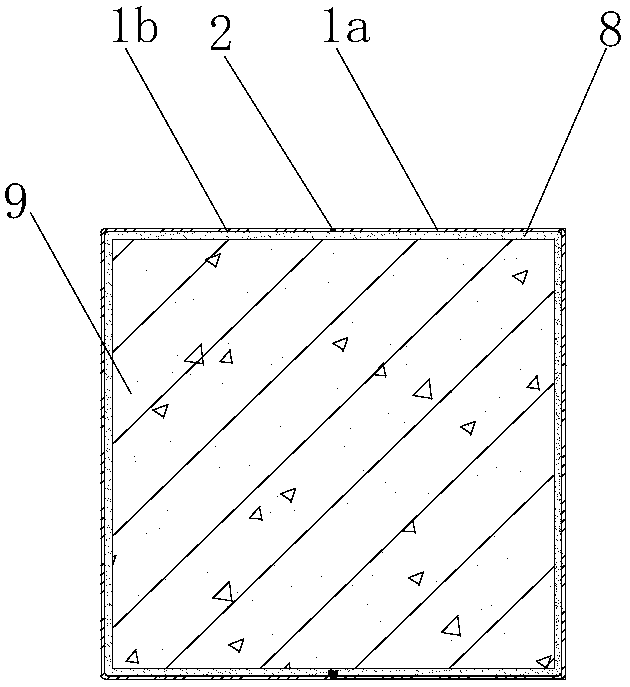

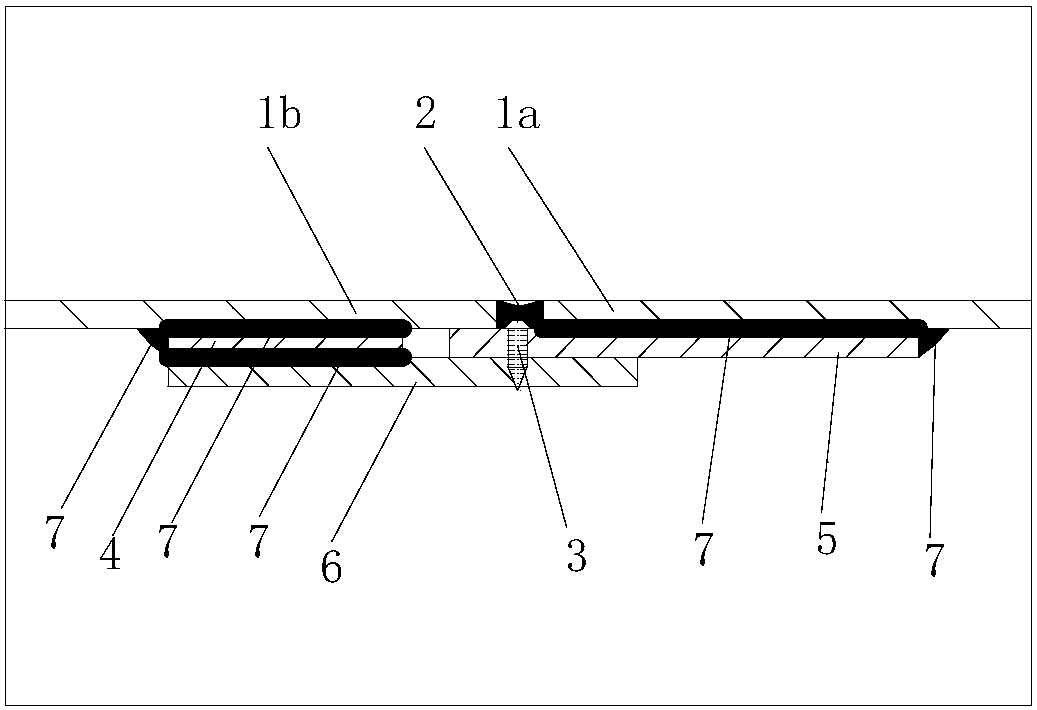

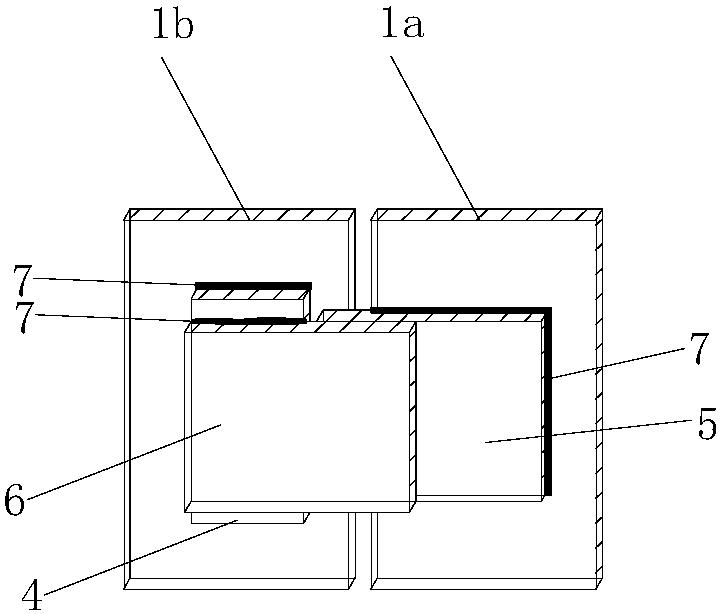

[0022] Such as figure 1 , figure 2 , image 3 An anti-collision steel plate wrapping column system shown includes a concrete column 9, a first U-shaped steel plate 1a, a second U-shaped steel plate 1b, and an inner lining panel assembly.

[0023] The first U-shaped steel plate 1a and the second U-shaped steel plate 1b are located on both sides of the column, and the U-shaped bending is customized. And there is a gap between the inner wall of the second U-shaped steel plate 1b and the concrete column 9 .

[0024] In this embodiment, the first U-shaped steel plate 1a and the second U-shaped steel plate 1b have a thickness of 6mm and a height of 150mm, and the surfaces of the steel plates are coated with epoxy zinc-rich primer and fluorocarbon paint.

[0025] The lining patch assembly is located at the joint between the first U-shaped steel plate 1a and the second U-shaped steel plate 1b, and is installed in the gap between the U-shaped steel plate and the concrete column 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com