An anchoring structure and reinforcement method for narrow coal pillars in gob-side entry retaining

An anchoring structure and narrow coal pillar technology, which is applied in earth-moving drilling, bolt installation, mining equipment, etc., can solve the problems of severe mine pressure, serious roadway fragmentation, difficult roadway maintenance, etc., and can resist the shear damage of surrounding rock. and compressive failure, improve the shear failure and compressive failure of surrounding rock, reduce the effect of pipe laying time and material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

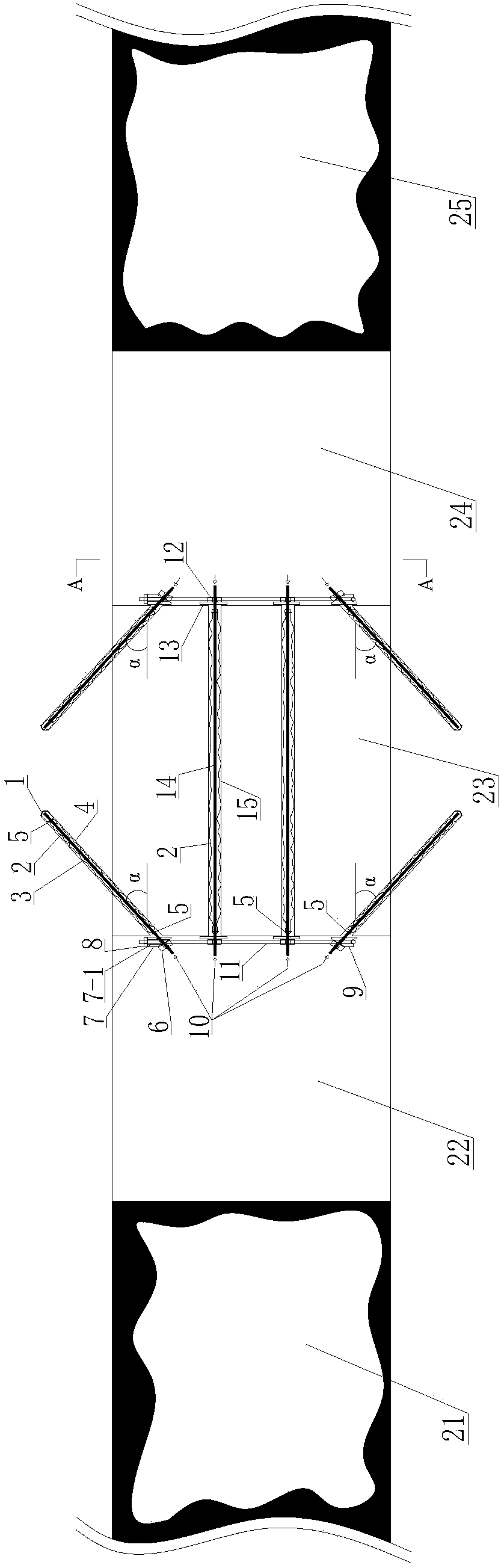

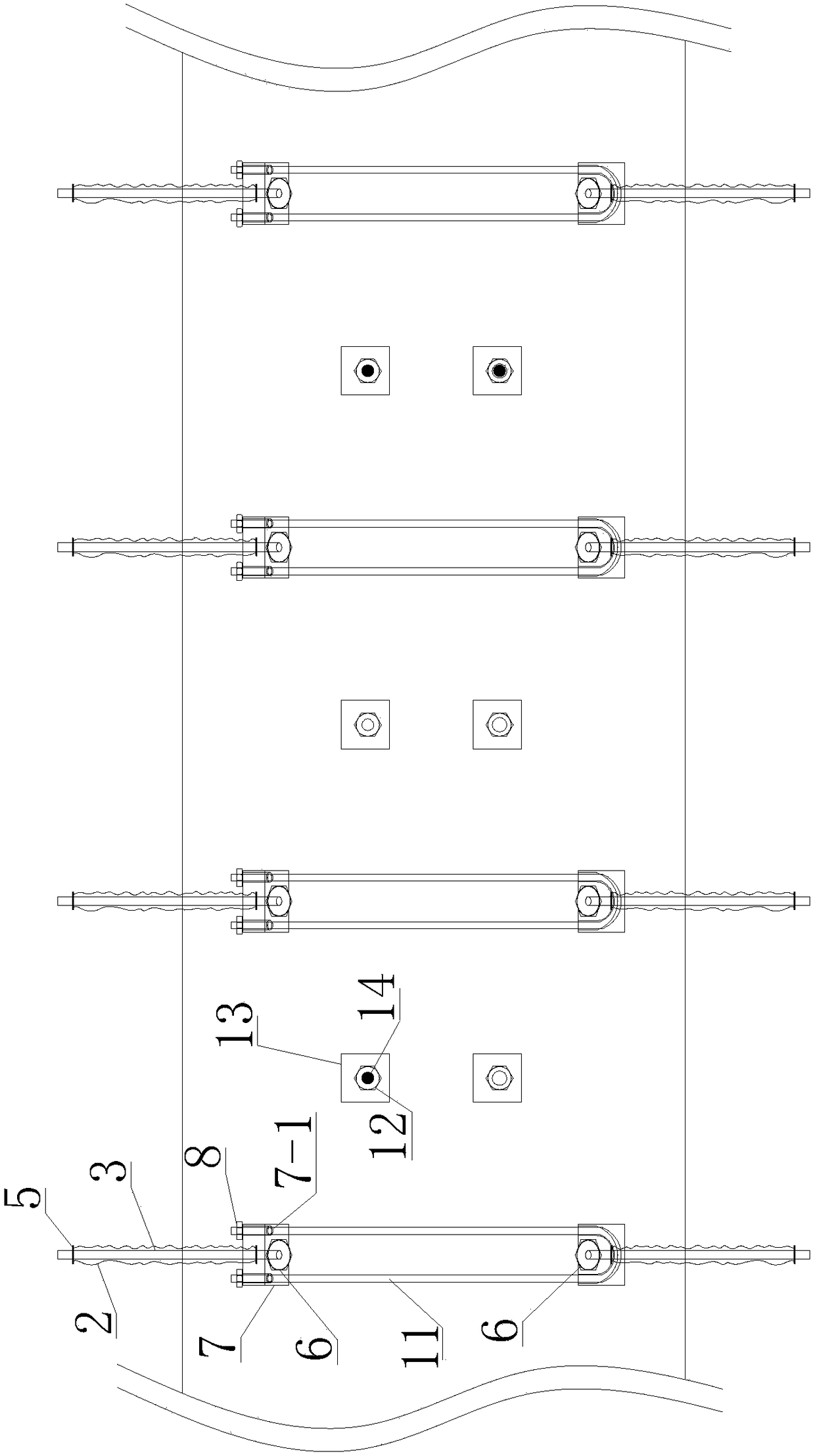

[0035] As shown in the figure, an anchoring structure for narrow coal pillars along the goaf, including cable-stayed anchoring systems and anchoring systems arranged at intervals along the length direction of the narrow coal pillars 23, the two sides of the narrow coal pillars 23 are respectively provided The upper section mining roadway 24 and the lower section gobside entry retention 22, the upper section mining roadway 24 and the lower section gobside entry retention 22 are respectively provided with an upper section mining face 25 and a lower section mining working surface Surface 21.

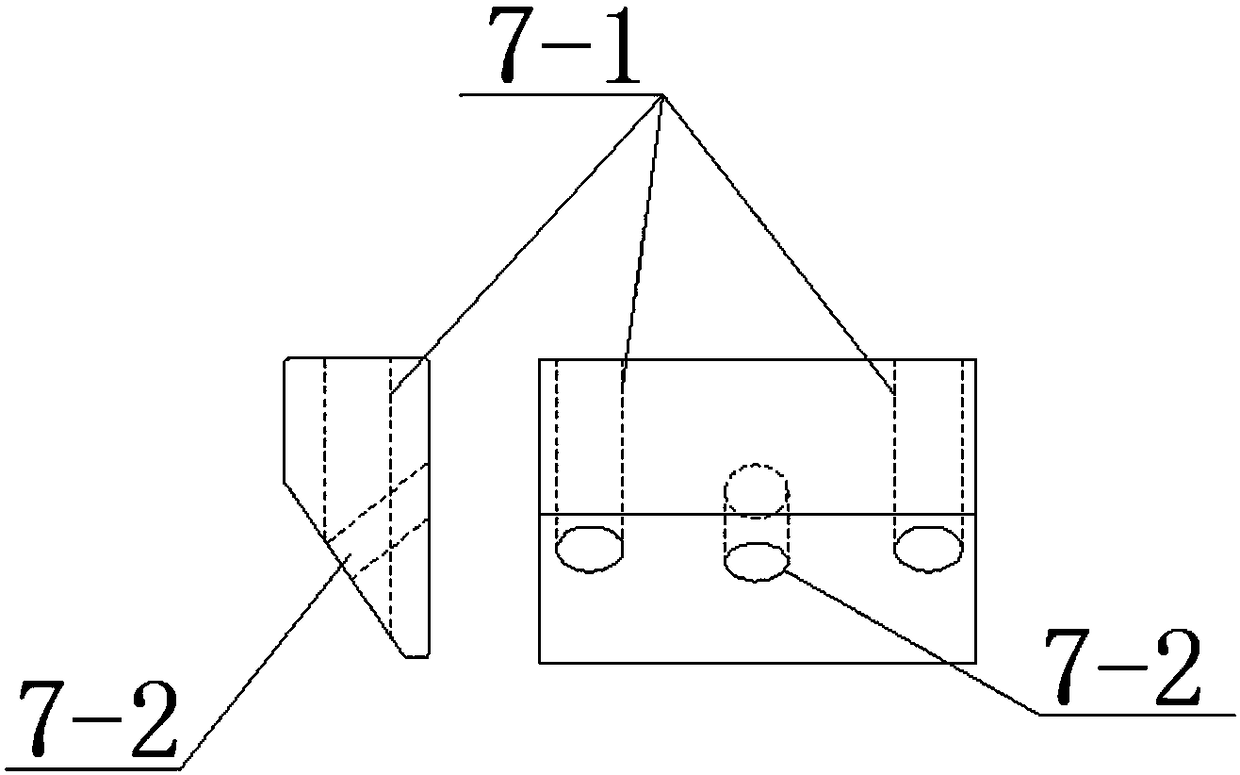

[0036]The cable-stayed anchoring system includes inclined grouting anchor rods 3 symmetrically installed on the four corners of the square section of the narrow coal pillar 23, and the two ends of the inclined grouting anchor rod 3 installed on the top plate of the narrow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com