Device for determining pressure and method for its manufacture

A pressure and extrusion force technology, applied in the field of pressure sensors, preferably high pressure sensors, and manufacturing devices for determining pressure, can solve problems such as material elongation, and achieve the effect of improving strength and good mechanical decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

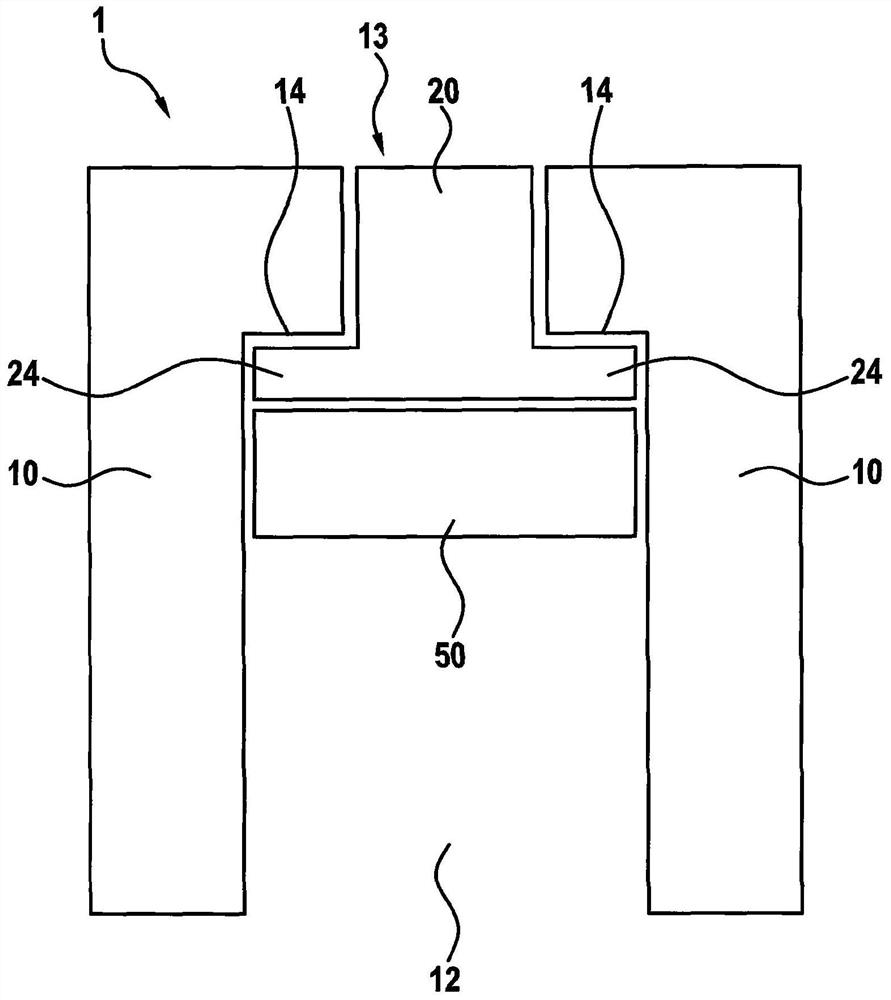

[0031] figure 1A schematic block diagram of a device 1 for determining pressure according to one embodiment of the invention is shown.

[0032] The device 1 has a housing 10 with a cavity 12 which has a mouth 13 which opens out from the cavity 12 to the outside of the housing 10 . The housing 10 also has a first sealing structure 14 . The device 1 also comprises a sensor device 20 with a second sealing structure 24 . The second sealing structure 24 cooperates with the first sealing structure 14 in such a way that the mouth 13 of the cavity 12 can be closed or is closed by the sensor device 20 by means of the first sealing structure 14 and the second sealing structure 24 .

[0033] The cavity is subjected to a pressure to be determined in that a fluid, which is charged with the pressure to be determined, is introduced into the cavity or has been introduced into the cavity, the sensor device 20 being designed to determine the Pressure to be determined.

[0034] The device 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com