High-accuracy heat and moisture exchanger moisture loss tester and working method thereof

A high-precision, exchanger technology, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of poor accuracy, poor accuracy of HME moisture loss tester, poor clinical reference, etc., to maintain Stable, compact structure, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

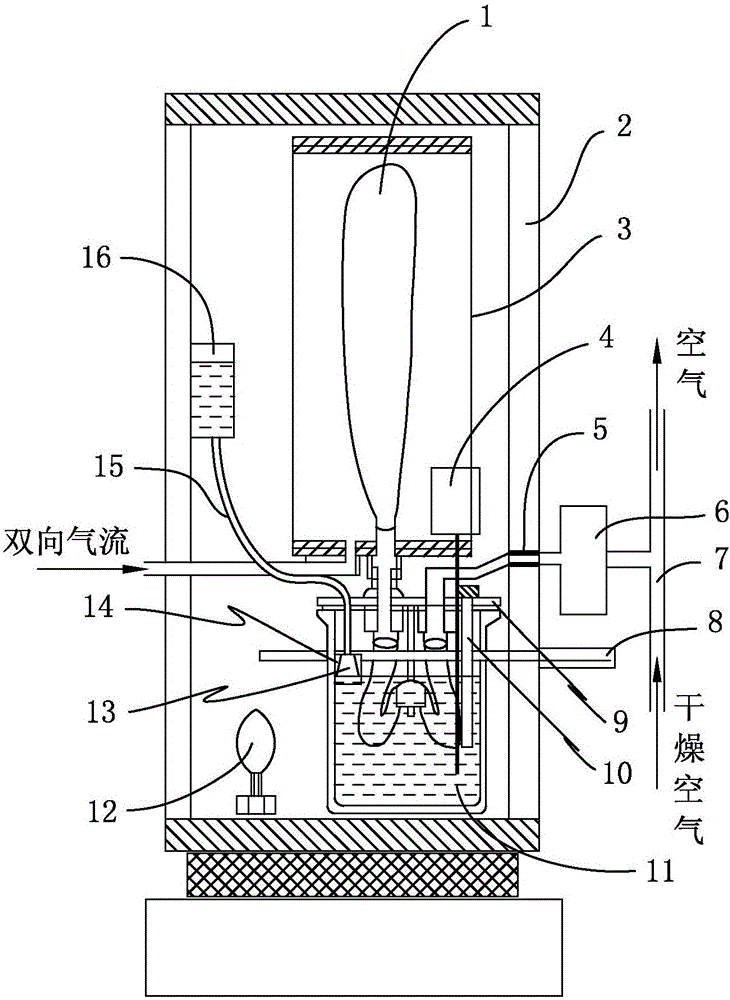

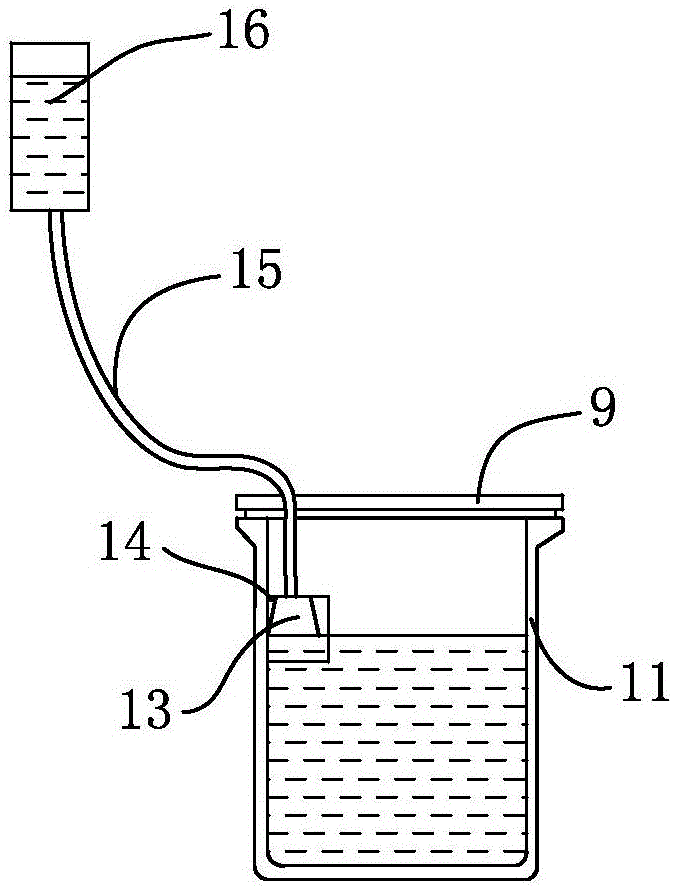

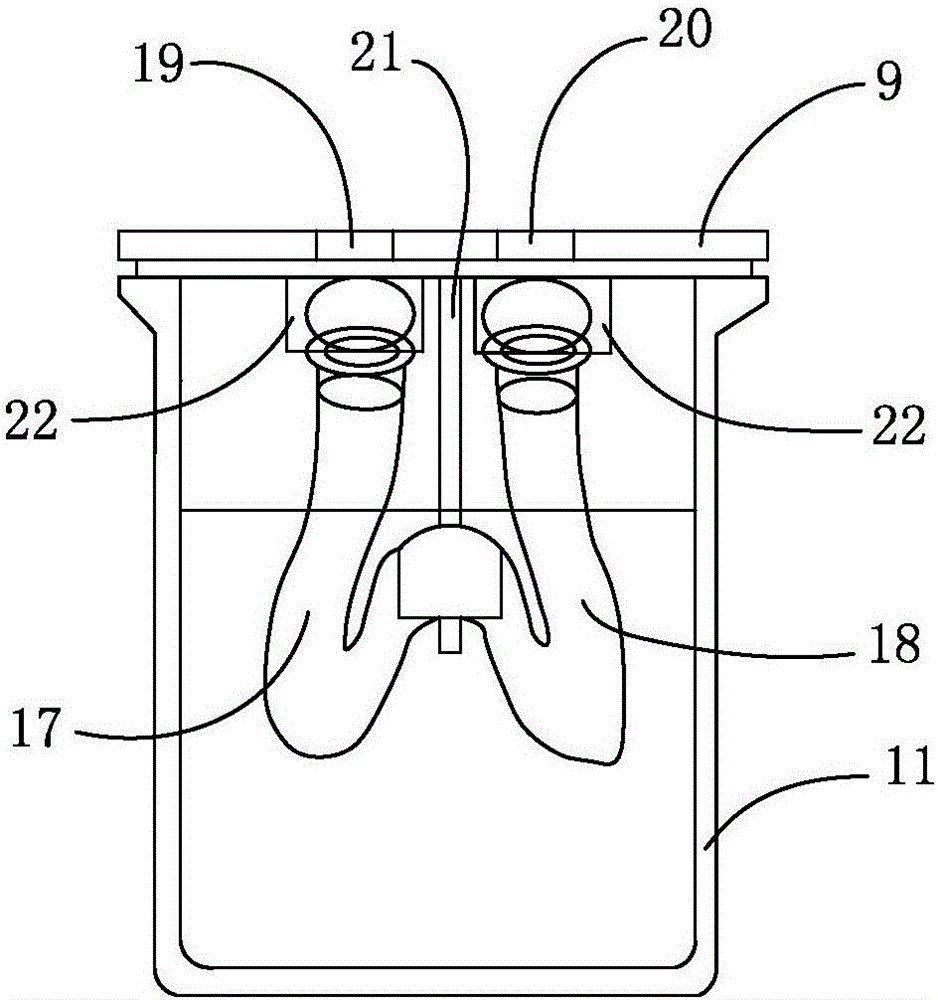

[0054] like figure 1 As shown, the high-precision heat and humidity exchanger moisture loss tester includes a water storage container 11, and the water storage container 11 forms a sealed connection with the cover plate 9 at its opening, and the interior of the water storage container 11 is provided with an exhalation pipeline 17 and inhalation pipeline 18; One end of the exhalation pipeline 17 is connected to the airbag 1 of the simulated human lung, and the other end of the exhalation pipeline 17 is passed into the water in the water storage container 11, and one end of the inhalation pipeline 18 is used In connection with the heat and moisture exchanger 6, the other end of the air suction pipeline 18 leads into the water in the water storage container 11; device 6, and the suction outlet communicates with the airbag 1.

[0055] li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com