Turbidity measuring circuit

A technology for measuring circuits and turbidity, which is used in measurement devices, measurement of scattering characteristics, and material analysis by optical means. High rate, the effect of suppressing zero drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below with reference to the accompanying drawings.

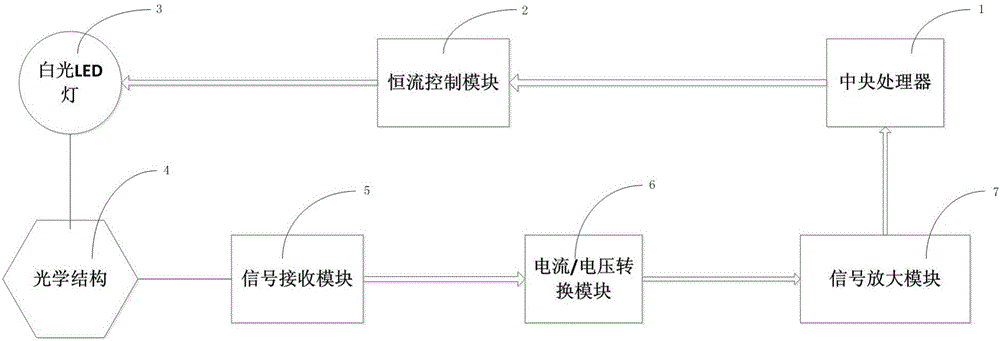

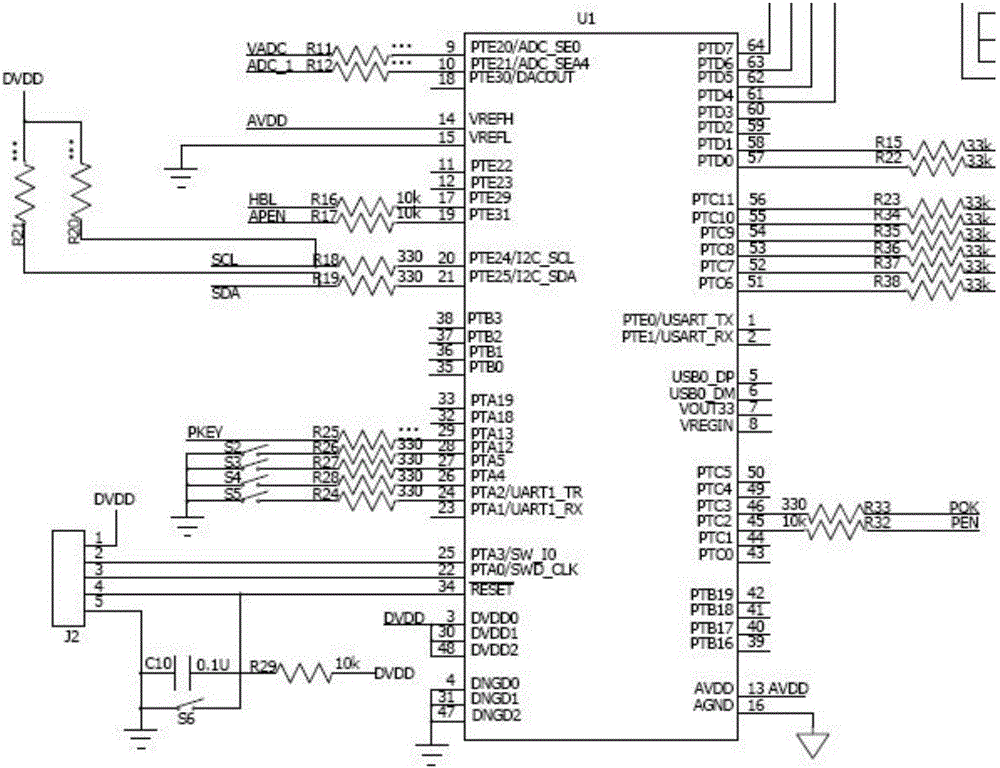

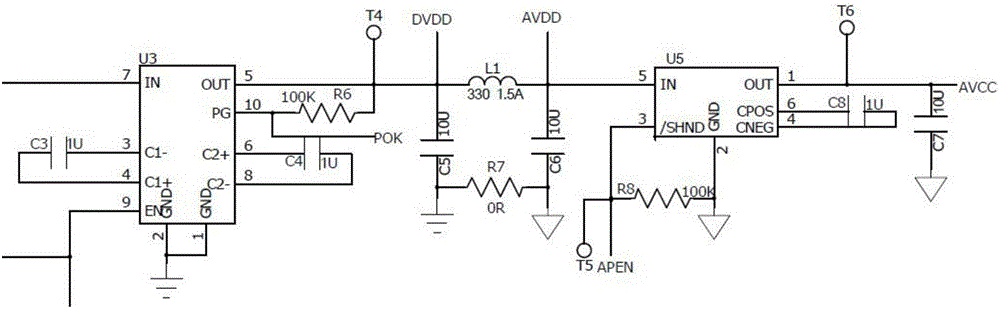

[0024] Please refer to the attached figure 1 to attach Figure 6 , in this embodiment, the turbidity measurement circuit includes: a central processing unit 1, the central processing unit 1 is electrically connected to the constant current control module 2, the constant current control module 2 is electrically connected to the white LED lamp 3, and the white light LED The lamp 3 acts on a signal receiving module 5 through an optical structure 4, the above signal receiving module 5 is coupled to the current / voltage conversion module 6, and the signal converted by the above current / voltage conversion module 6 is sent to the The above-mentioned central processing unit 1, wherein the solution to be detected is placed on the optical structure 4 for scattering. The central processing unit 1 controls the constant current control module 2 to provide a stable current for the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com