Leading production arrangement method and system

A generation system and leader technology, applied in the field of textile production, can solve problems such as waste of cost materials, poor accuracy, etc., and achieve the effects of avoiding waste, ensuring lean production, and facilitating monitoring and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

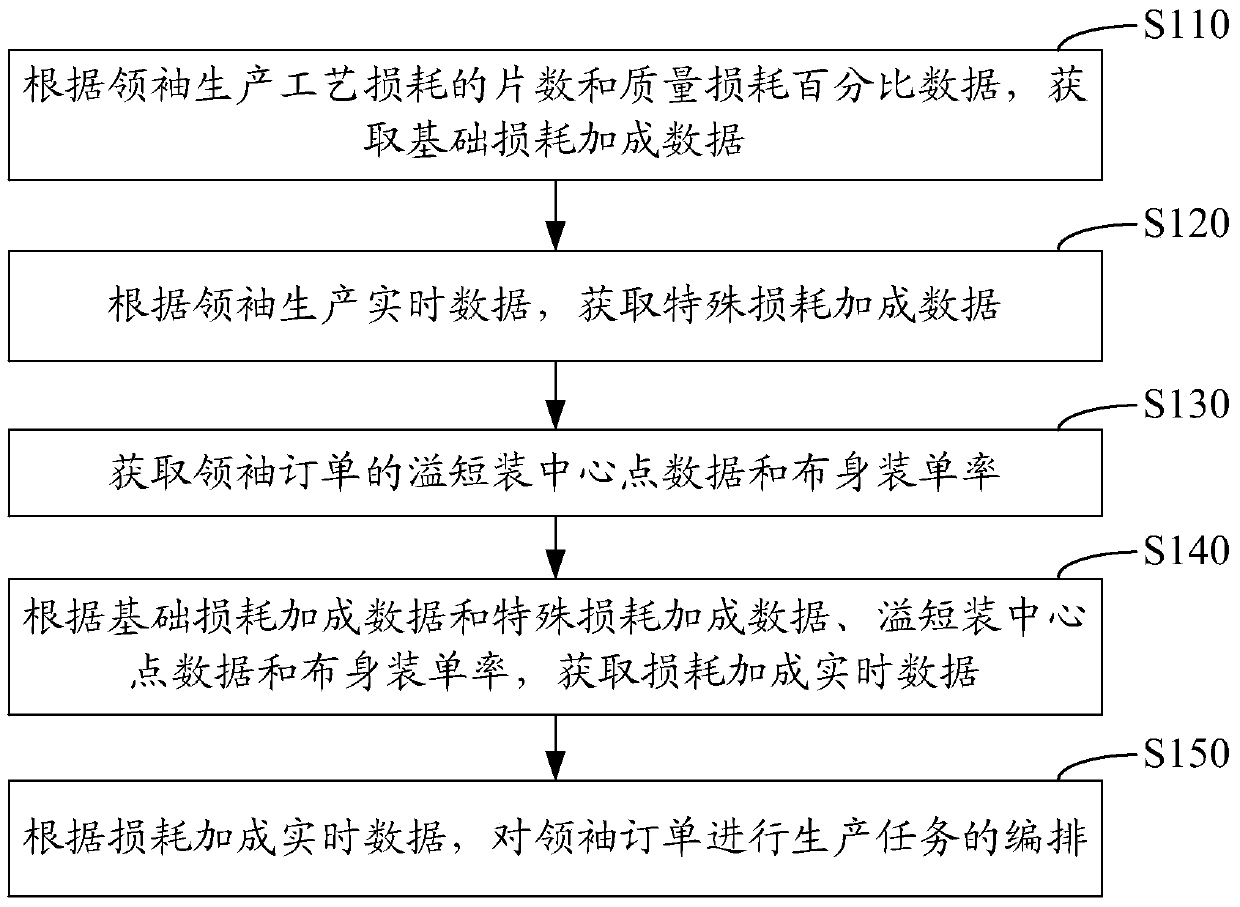

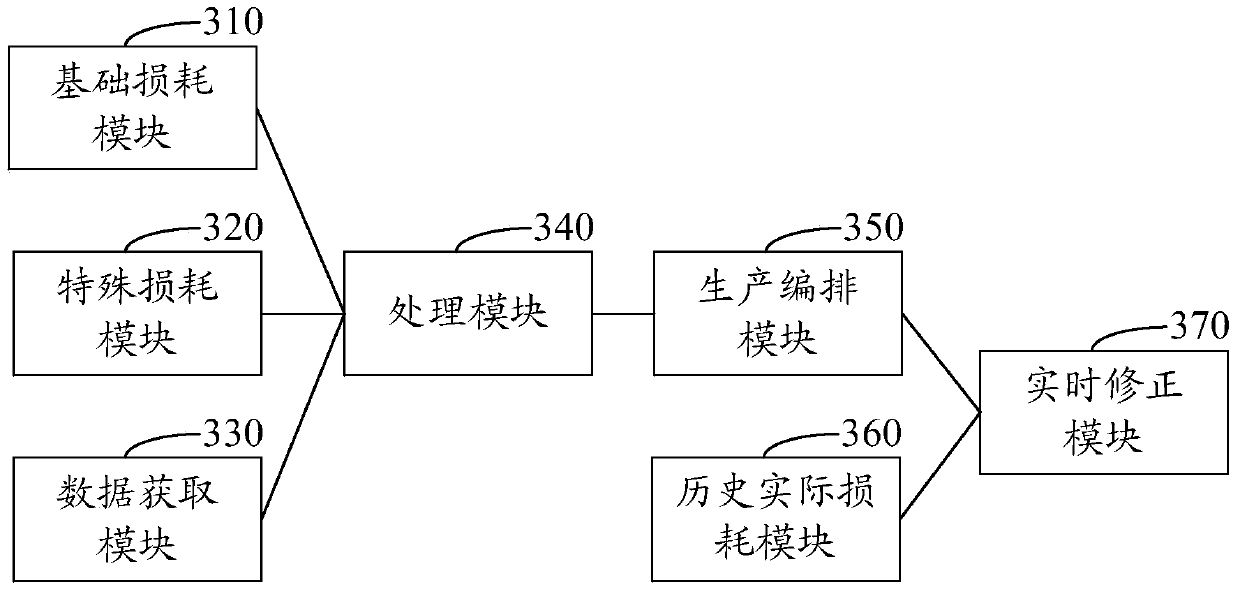

[0027] In order to solve the problem that the traditional production scheduling method is prone to waste of cost and materials due to the poor accuracy of loss addition, the present invention provides a leader production scheduling method Example 1; figure 1 It is a schematic flow chart of Embodiment 1 of the leader production arrangement method of the present invention; as figure 1 As shown, the following steps may be included:

[0028] Step S110: According to the number of pieces lost in the leader's production process and the percentage of mass loss, the basic loss addition data is obtained; the loss of the leader's production process includes the loss of relevant production materials based on each production process in the leader's production process;

[0029] Specifically, the leading production process loss can include dyeing and finishing quality loss, cutting sample loss, cloth head and cloth tail loss, and small order additional loss;

[0030] Step S120: According to...

specific Embodiment

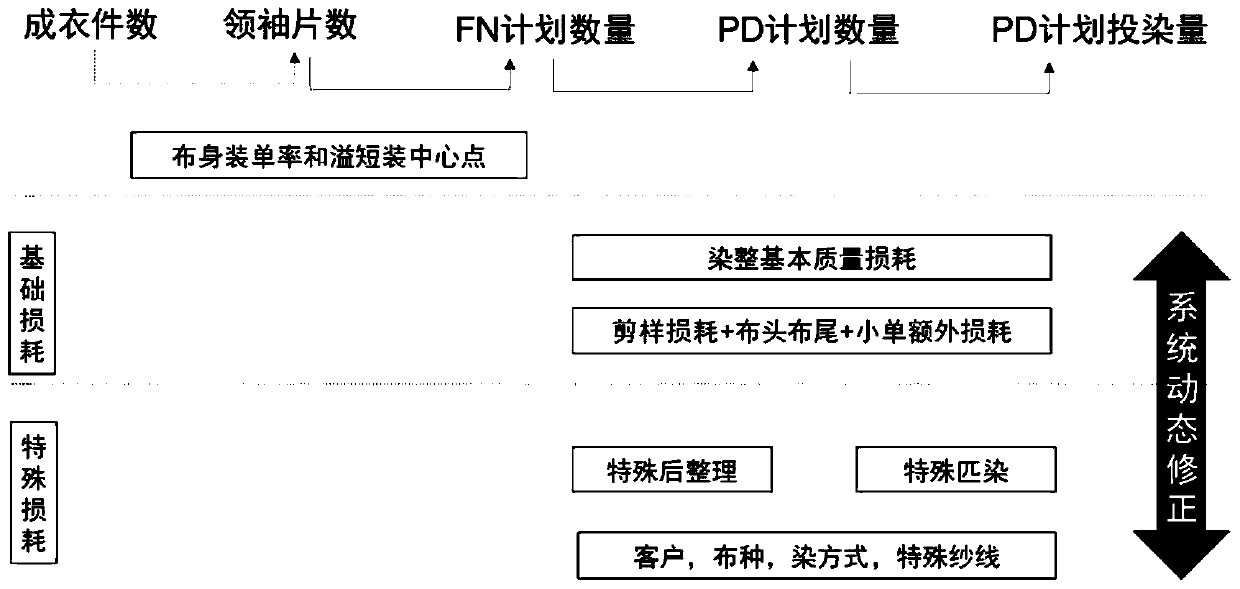

[0056] In order to further illustrate the technical solution of the present invention, the actual production process is taken as an example to illustrate the technical realization process of the present invention; figure 2 It is a schematic flow diagram of a specific embodiment of the leader production arrangement method of the present invention; as figure 2 Shown, the realization process of the present invention can be:

[0057] Implementation step 1: Obtain real-time loss bonus data;

[0058] Real-time loss bonus data = (basic loss + special loss) * ((overload and short load center point + cloth body load rate) / 2+100%)

[0059] Among them, basic loss = dyeing and finishing quality loss + cutting sample loss + cloth head and cloth tail + small order additional loss

[0060] Special loss needs to be determined according to specific actual production requirements and data analysis

[0061] Quality loss in dyeing and finishing: PD 3%, YD&HT 2%;

[0062] Cutting loss: mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com