Method of dividing wafer

A technology for wafers and dicing lanes, which is applied in the field of wafer division, can solve the problems of increased cost and complicated wafer processing procedures, and achieves the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

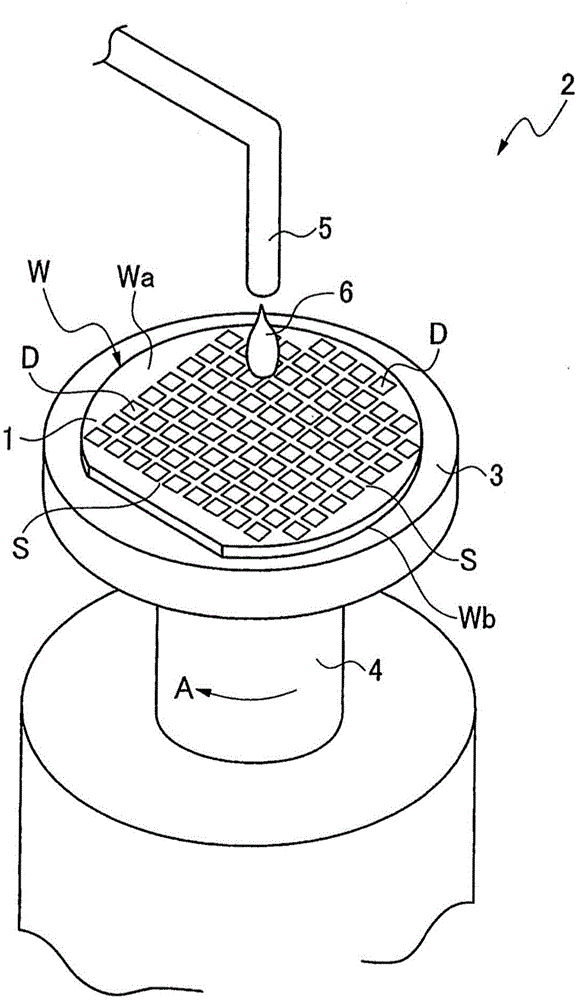

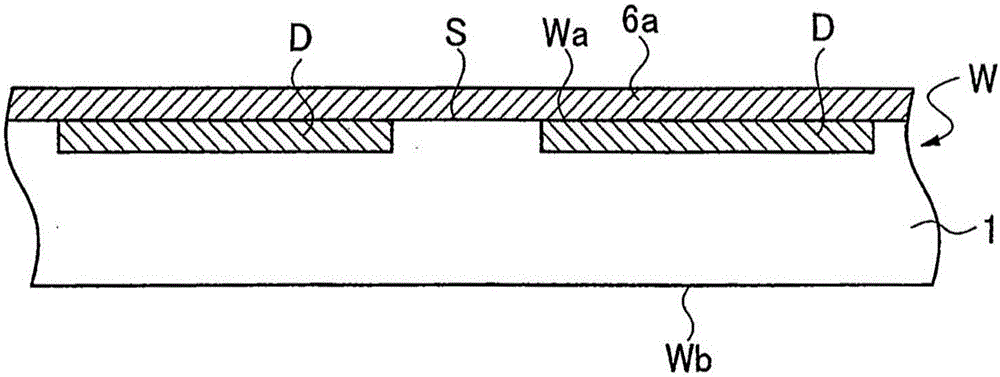

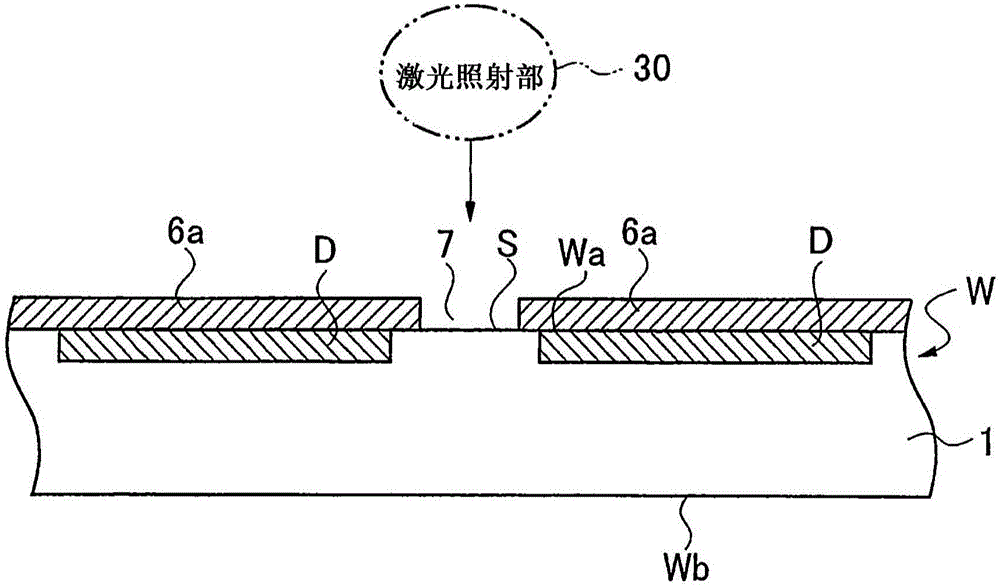

[0047] figure 1 The wafer W shown is an example of a workpiece, and includes a disc-shaped substrate 1 . A plurality of scribe lines S are formed on the front surface Wa of the wafer W, and devices D are formed in each of the areas divided by the plurality of scribe lines S. As shown in FIG. The surface on the opposite side to the front Wa constitutes the back surface Wb ground by a grinding die or the like. Next, a wafer dividing method for dividing the wafer W into individual devices D will be described.

[0048] (1) Protective film formation process

[0049] Such as figure 1 As shown, for example, a water-soluble protective film is formed on the front surface Wa of the wafer W using a spin coater 2 . The spin coater 2 has a spin table 3 that holds a wafer W and is rotatable. A rotating shaft 4 having an axis in the vertical direction is connected below the rotating table 3 . A nozzle 5 for ejecting a material liquid of a water-soluble protective film is arranged above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com