Electrical connectors for circuit boards

A technology for circuit substrates and electrical connectors, applied in the direction of conductive connection, circuit, connection, etc., can solve the problem of poor contact state of the elastic displacement terminal of the contact arm, poor contact of the target terminal, and the inability to fully obtain the elastic displacement state of the contact arm, etc. problem, to achieve the effect of ensuring the elastic displacement state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

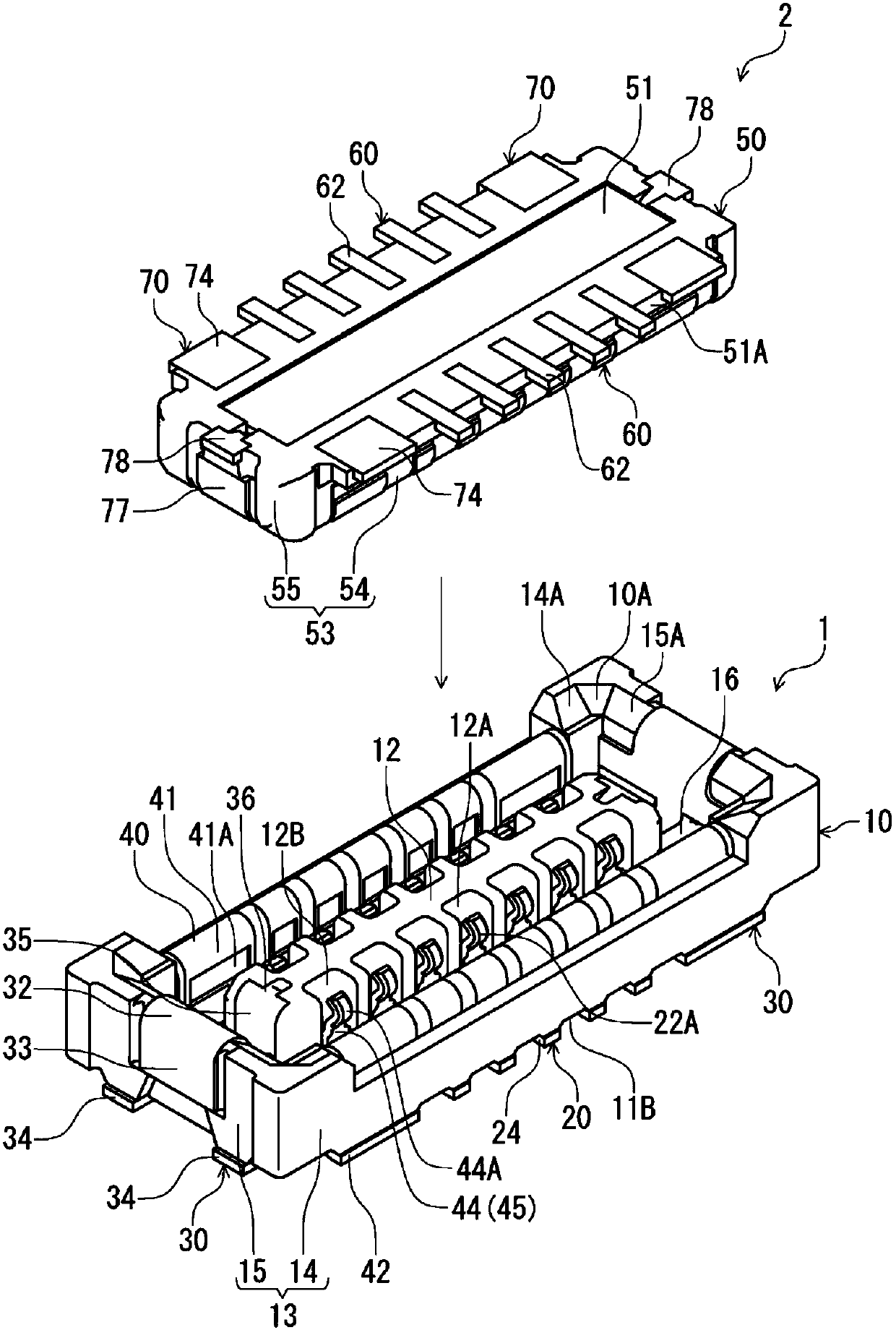

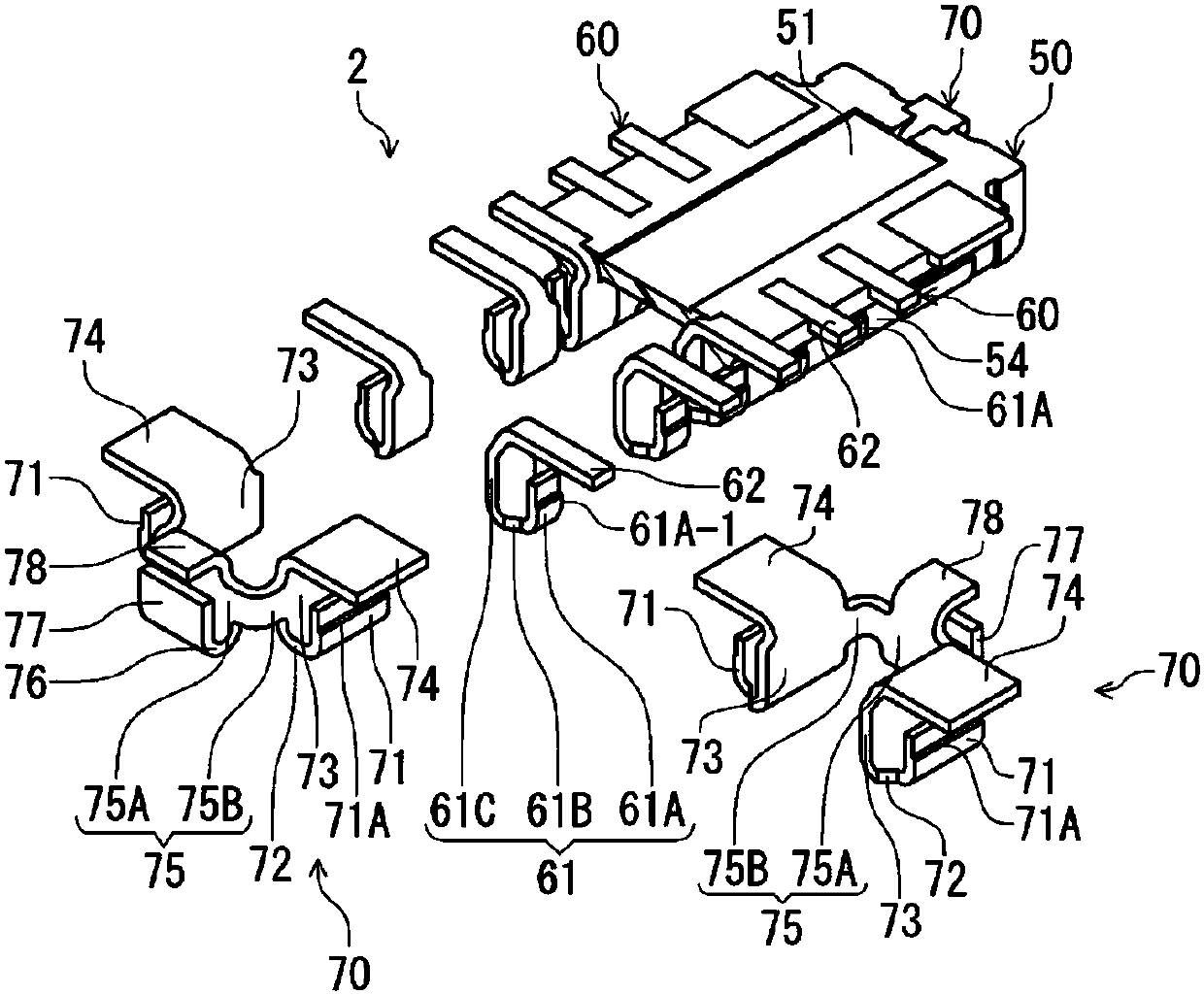

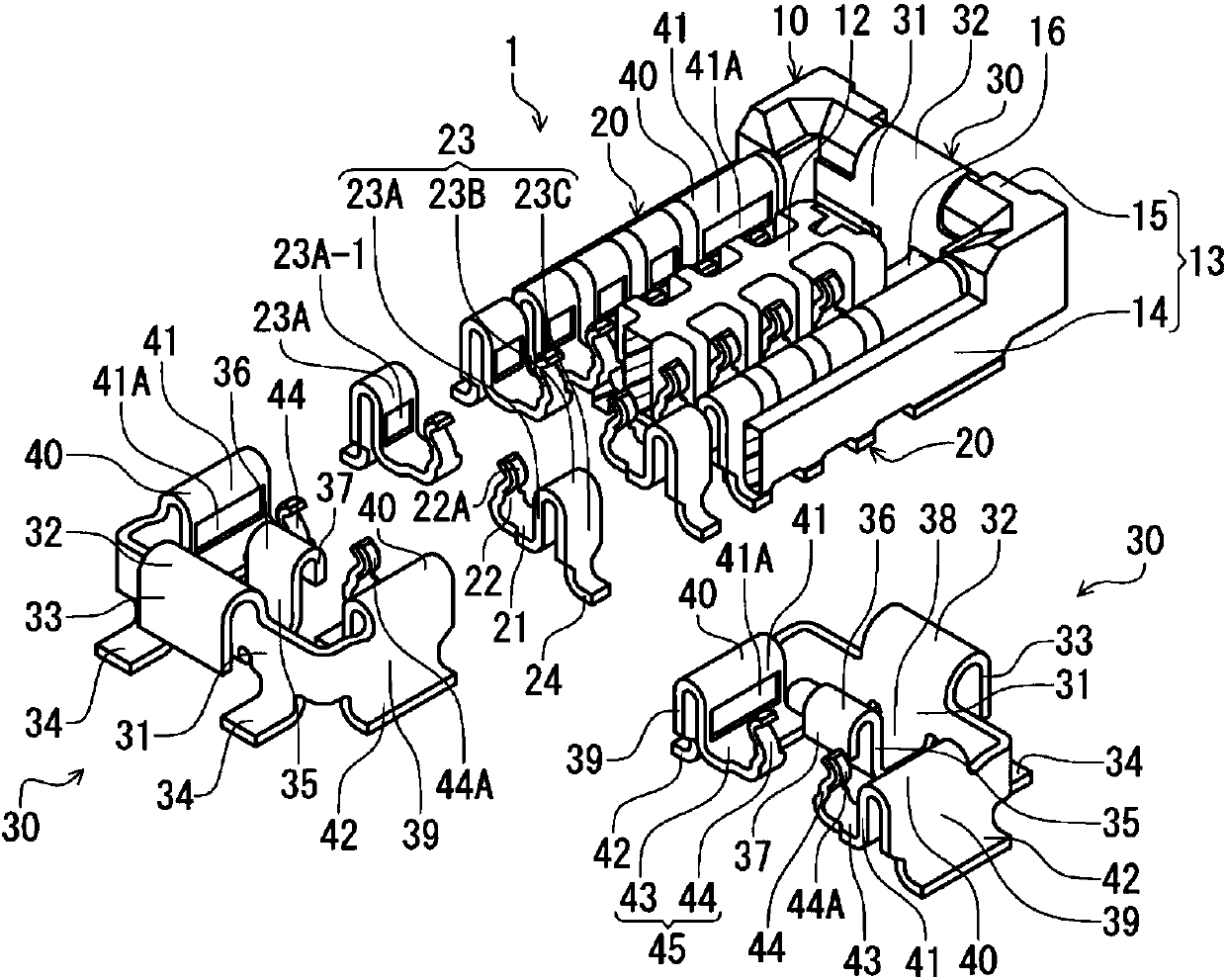

[0029] Embodiments of the present invention will be described below based on the drawings.

[0030] figure 1 It is a perspective view of the receptacle connector of this embodiment and the plug connector which is a target connector mated with it from above, and shows the state before connector mating. The receptacle connector 1 and the plug connector 2 in this embodiment are electrical connectors for circuit boards respectively disposed on the mounting surfaces of different circuit boards (not shown), and are configured so that they are at right angles to the mounting surfaces of the respective circuit boards. direction( figure 1 The up and down direction in) becomes the connector assembly in the plugging and unplugging direction. In this embodiment, the fitting direction of the plug connector 2 with respect to the receptacle connector 1, that is, figure 1 The direction in which the plug connector 2 moves downward is set as the "connector fitting direction", and the opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com