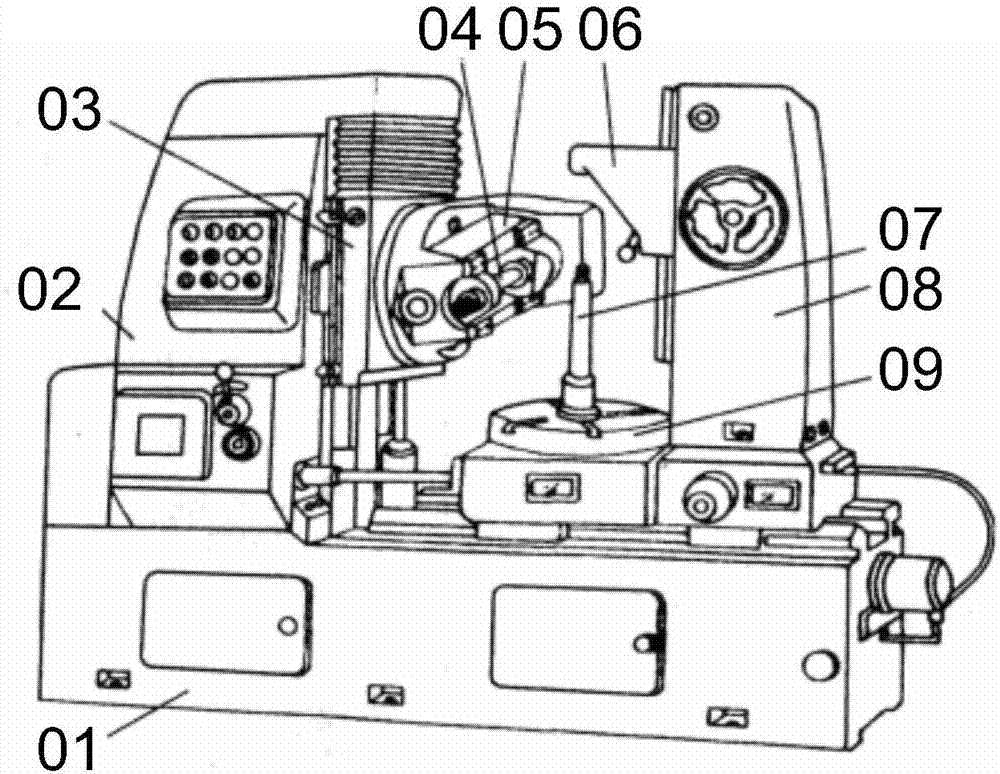

hobbing machine hob

A hob and gear hobbing machine technology, which is applied in the direction of gear cutting machines, gear teeth, mechanical equipment, etc., can solve the problems of complex structure and large space occupation, and achieve the effects of reducing labor intensity, simple structure, and reducing space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

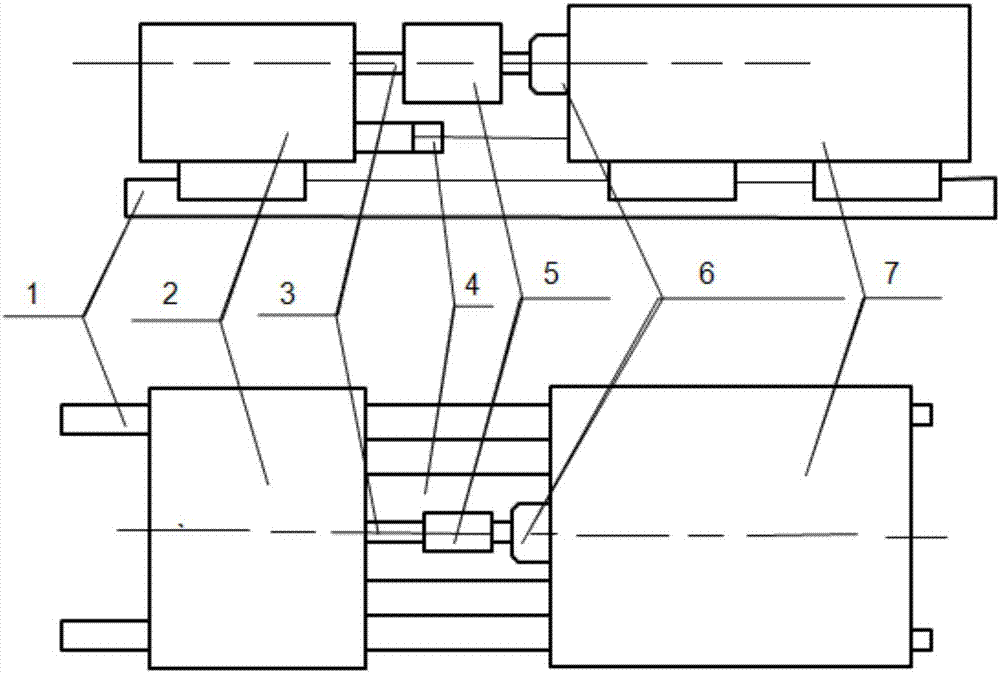

[0023] See figure 2 , the present invention provides a hob frame for a gear hobbing machine, which is composed of a guide rail pair 1, a hob tailstock 2, a tailstock shaft 3, an oil cylinder 4, a hob 5, a hob shaft 6 and a hob headstock 7, wherein,

[0024] The hob tailstock 2 is connected to the hob headstock 7 through the oil cylinder 4;

[0025] The tailstock shaft 3 is mounted on the hob tailstock 2, and the hob shaft 6 is mounted on the hob headstock 7;

[0026] The hob shaft 6 supports or installs one end of the hob 5, and the tailstock shaft 3 supports the other end of the hob 5;

[0027] The oil cylinder 4 provides the axial support force of the tailstock shaft 3 to the hob 5 .

[0028] Further, the hob headstock 7 and the hob tailstock 2 share the same guide rail pair 1 when moving; the hob headstock 7 moves on the guide rail pair 1, and the hob tailstock 2 Moving on the guide rail pair 1, the hob tailstock 2 moves with the hob headstock 7, and the hob tailstock 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com