Manipulator for tire vulcanizing machine

A tire vulcanization and manipulator technology, applied in the field of manipulators, can solve problems such as low efficiency and troublesome adjustment, and achieve the effects of high efficiency, fast adjustment speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] refer to Figure 5 , there is an existing manipulator that adopts the adjustment method of the adjustment screw 15 and the adjustment nut 16. When replacing each kind of steel ring embryo of different specifications, it is necessary to loosen the two adjustment nuts 16, turn the adjustment screw 15, and adjust After the required steel ring size is reached, the adjusting nut 16 is locked, which is troublesome and inefficient to adjust.

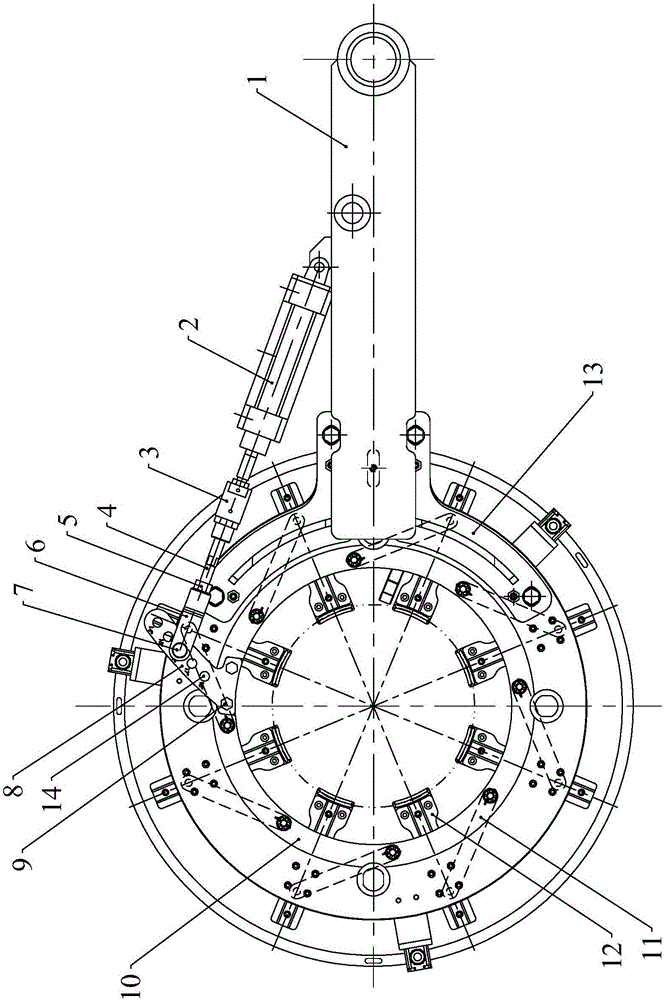

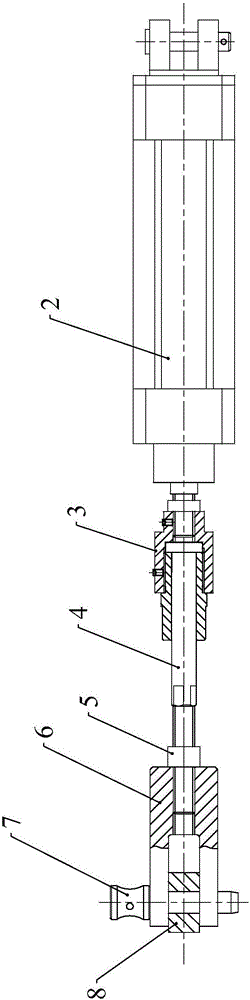

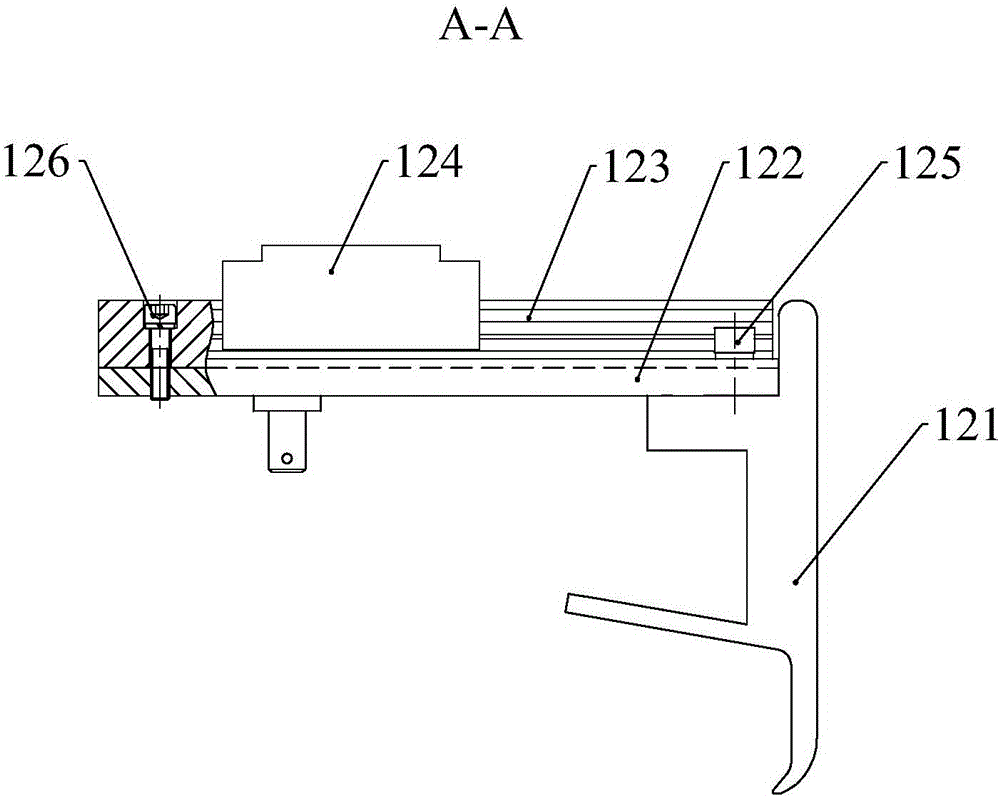

[0018] refer to Figure 1 to Figure 2 , the present embodiment is a manipulator for a tire vulcanizing machine, including a rotating arm 1, a rotating disk assembly 10, eight connecting rods 11, eight claw assembly 12, a fixed disk assembly 13 and an adjusting steel ring mechanism, the rotating arm One end is installed on the vulcanizer, and the other end of the rotating arm is connected to the fixed plate assembly; the claw assembly is fixed on the fixed plate assembly, the turntable assembly is connected to the claw assembly through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com