Preparation method of organic fluorine hydrophobic chain extender containing ionic liquid

An organic fluorine and hydrophobic technology, applied in the field of preparation of organic fluorine hydrophobic chain extenders, can solve the problems of complex production operation process and insignificant improvement of surface strength, and achieve the effect of good hydrophobic performance and improved stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

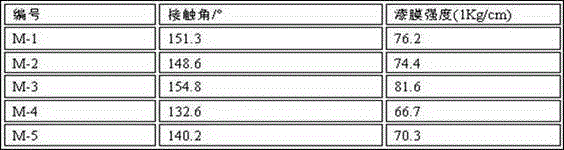

Embodiment 1

[0014] In a 1000L reactor, add 150Kg of water, 100Kg of styrene, 40Kg of 1-vinyl-3-ethylimidazole hexafluorophosphate solution (mass concentration 20%), 1-vinyl-3-butylimidazole tetrafluoroboron Salt solution (mass concentration 20%) 40Kg, 6,6,7,7,8,8,8-heptafluoro-5,5-bis(trifluoromethyl)-1,3-octadiene 8Kg, 1 5 9-Cyclododecatriene 1Kg, benzoyl peroxide 1Kg, react at 100°C for 10 hours, remove unreacted reactants after the reaction, filter the product, and dry to obtain organic fluorine hydrophobic chain extension agent. The resulting product number was M-1.

Embodiment 2

[0016] In a 1000L reactor, add 150Kg of water, 100Kg of styrene, 30Kg of 1-vinyl-3-ethylimidazole hexafluorophosphate solution (mass concentration 20%), 1-vinyl-3-butylimidazole tetrafluoroboron Salt solution (mass concentration 20%) 30Kg, 6,6,7,7,8,8,8-heptafluoro-5,5-bis(trifluoromethyl)-1,3-octadiene 5Kg, 1 5 9-Cyclododecatriene 0.5Kg, benzoyl peroxide 0.5Kg, react at 80°C for 8 hours, remove unreacted reactants after the reaction, filter the product, and dry to obtain organic fluorine hydrophobic chain extender. The resulting product number was M-2.

Embodiment 3

[0018] In a 1000L reactor, add 150Kg of water, 100Kg of styrene, 50Kg of 1-vinyl-3-ethylimidazole hexafluorophosphate solution (mass concentration 20%), 1-vinyl-3-butylimidazole tetrafluoroboron Salt solution (mass concentration 20%) 50Kg, 6,6,7,7,8,8,8-heptafluoro-5,5-bis(trifluoromethyl)-1,3-octadiene 10Kg, 1 5 9-Cyclododecatriene 2Kg, benzoyl peroxide 2Kg, react at 120°C for 12 hours, remove unreacted reactants after the reaction, filter the product, and dry to obtain organic fluorine hydrophobic chain extension agent. The resulting product number was M-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com