Construction method of high-rise steel structure frame beam

A technology of steel structure frame and construction method, applied in truss-type structures, joists, girders and other directions, can solve the hidden dangers of high-altitude construction safety, without considering cranes, safety risks and other problems, to improve construction quality and construction efficiency, solve the Construction safety issues and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0045] The construction sequence of the steel structure frame is: 1. Installation of frame columns; 2. Installation of frame steel beams; Stage framing column installation….

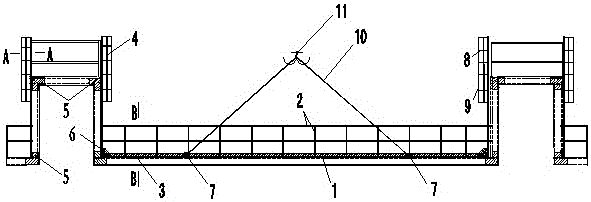

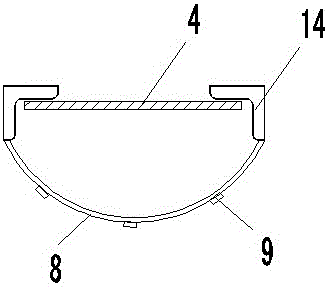

[0046] attached Figure 1-4 It can be known that a high-rise steel structure frame beam construction method comprises the following steps:

[0047] Step 1, steel structure construction sequence frame steel beams are installed in place;

[0048] Step 2, using the hoisting machine to move the bridge to a connection end point of a group of opposite steel beams installed in place;

[0049] Step 3, hoisting in place across the bridge:

[0050] In step 4, the construction personnel carry out the construction work of the connection point through the bridge: bolt connection, welding or bolt welding processing operation;

[0051] Step 5, the construction operation of a connection end point of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com