Modular flowmeter

A flow meter, modular technology, applied in the direction of volume/mass flow generated by mechanical effects, through detection of dynamic effects of fluid flow, etc., can solve the problems of short service life, low precision, etc., to reduce wear, prolong service life, good aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

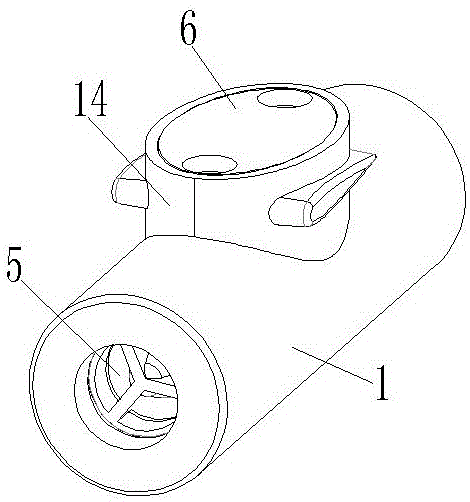

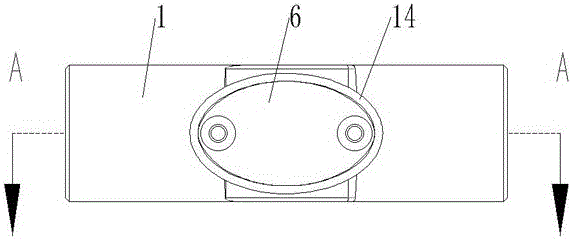

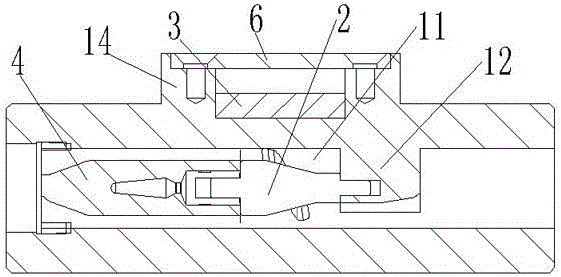

[0034] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the modular flowmeter includes a casing 1 with a fluid passage 11 inside, and a centripetal turbine 2 is installed in the fluid passage 11. The materials of the casing 1 and the centripetal turbine 2 are nylon magnets. The middle part of the centripetal turbine 2 is a truncated cone-shaped turbine shaft 21, and a helical blade 22 is installed on the side wall of the middle part of the turbine shaft 21, which improves the conversion rate of the fluid and the impeller speed. A sensor 3 is also mounted on the outer side of the housing 1 . When in use, install the flowmeter on the fluid pipeline that needs to be measured according to the installation instructions. After the fluid to be measured passes through the fluid passage 11, the spiral blade 22 of the centripetal turbine 2 rotates under the impact of the fluid to be measured, and the sensor 3 detects the direction of flow. The rotation speed of heart tur...

Embodiment 2

[0036] like Figure 10 , Figure 11 and Figure 12 As shown, the difference between this embodiment and Embodiment 1 lies in the number of helical blades 22. In this embodiment, the number of helical blades 22 is two, and the direction of rotation of the two helical blades 22 is the same. A spiral channel 23 is formed between them. After the fluid to be tested passes through the spiral channel 23, the fluid to be tested will generate a force opposite to the flow direction on the turbine to balance part of the impact force of the fluid.

Embodiment 3

[0038] like image 3 , Figure 6 , Figure 7 and Figure 9 As shown, the difference between this embodiment and Embodiment 2 lies in the installation method of the centripetal turbine 2. In this embodiment, a support 12 is fixed in the fluid channel 11, and a plurality of fan-shaped openings for fluid passage are opened on the support 12. Opening 5, a plugging core 4 is installed in the fluid channel 11. The material of the plugging core 4 is nylon. The turbine 2 is fixed on the support 12 to ensure that the centripetal turbine 2 will not shake freely in the fluid passage 11, and avoid the unstable movement of the centripetal turbine 2 from affecting the stability of flow monitoring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com