Robot-based gluing quality on-line visual detection device and method

A visual inspection device and robot technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of not being able to control multiple sets of visual inspection units, and achieve the effects of prolonging operation time, improving adaptability, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

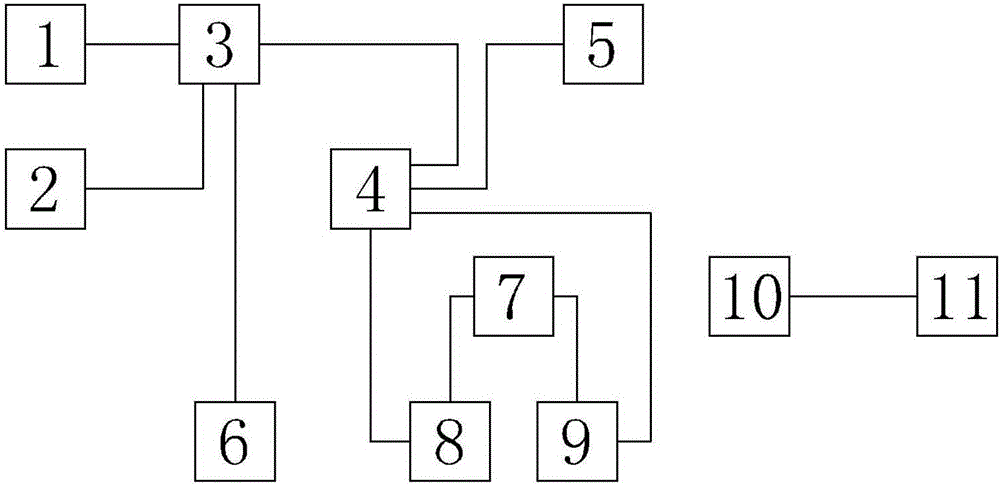

[0030] refer to figure 1 , an on-line visual detection device for robot gluing quality, comprising a display 1, a keyboard and mouse 2, an industrial computer 3, a PCI-E network card 4, a robot controller 5, a light source controller 6, a mounting bracket 7, a light source 8, 2 or Multiple cameras 9 , glue guns 10 and robots 11 . The light source 8 is a ring light source and is installed on the glue gun 10 through the mounting bracket 7 . The camera 9 is installed inside the light source 8 ; the glue gun 10 is installed on the robot 11 .

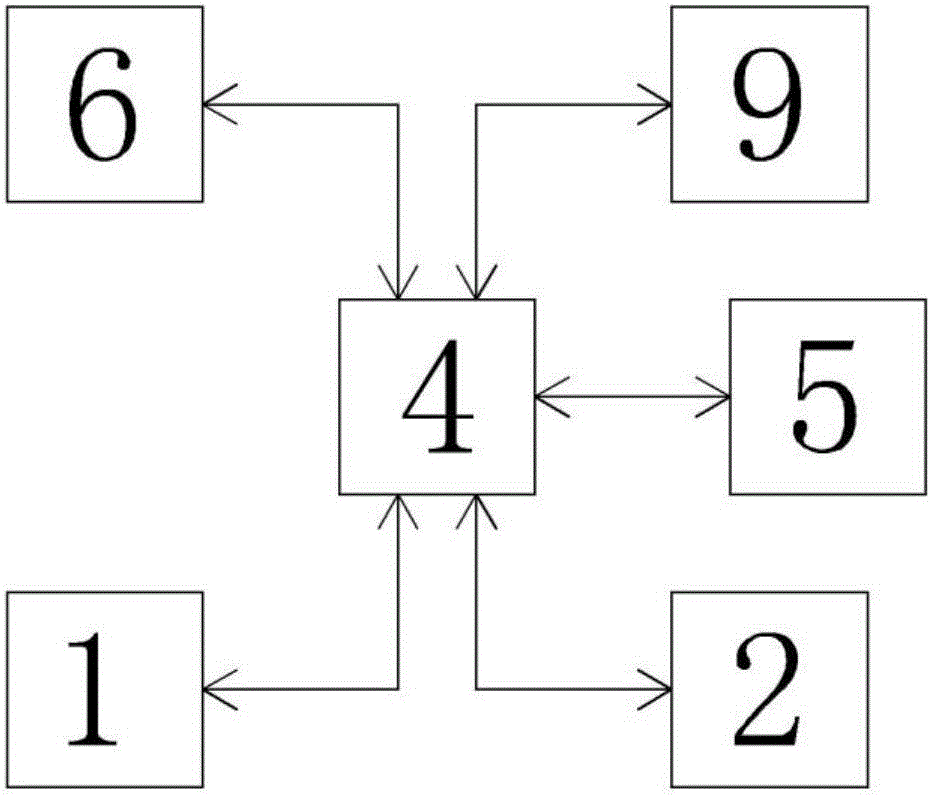

[0031] refer to figure 2 The communication between robot 11, camera 9 and computer all adopts TCP / IP network communication, light source controller 6 and computer adopt RS232 interface communication, display 1 and computer adopt RS485 communication, keyboard and mouse 2 adopt USB mode communication with computer.

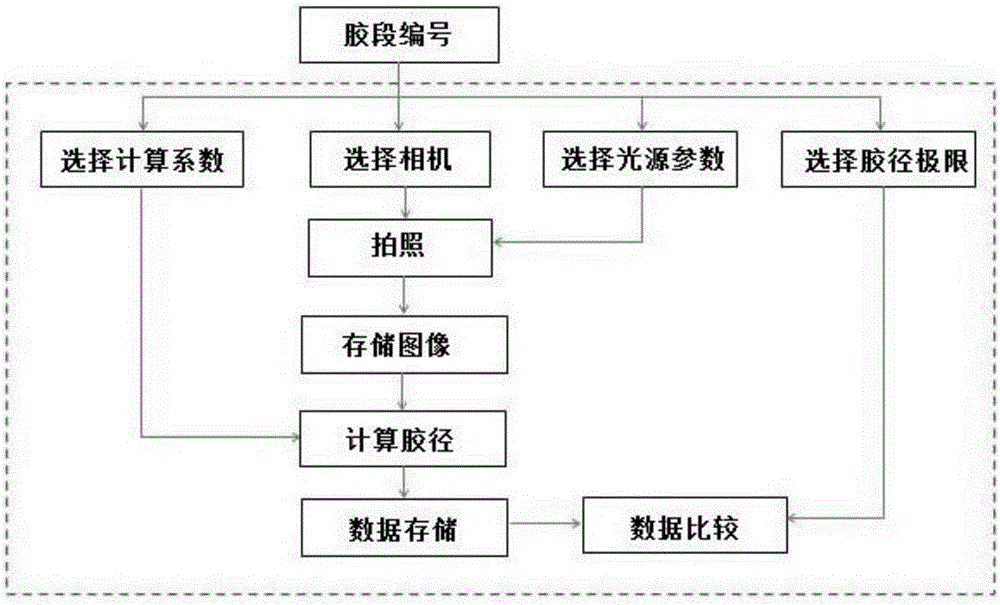

[0032] The present invention is based on the database information, and the stored data table in the computer includes: a cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com