Method for determining residual stress of sealing ring of solid rocket engine under high pressure

A solid rocket, residual stress technology, applied in special data processing applications, force/torque/power measuring instruments, instruments, etc., can solve the problem that the residual stress of the sealing ring is difficult to be directly detected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

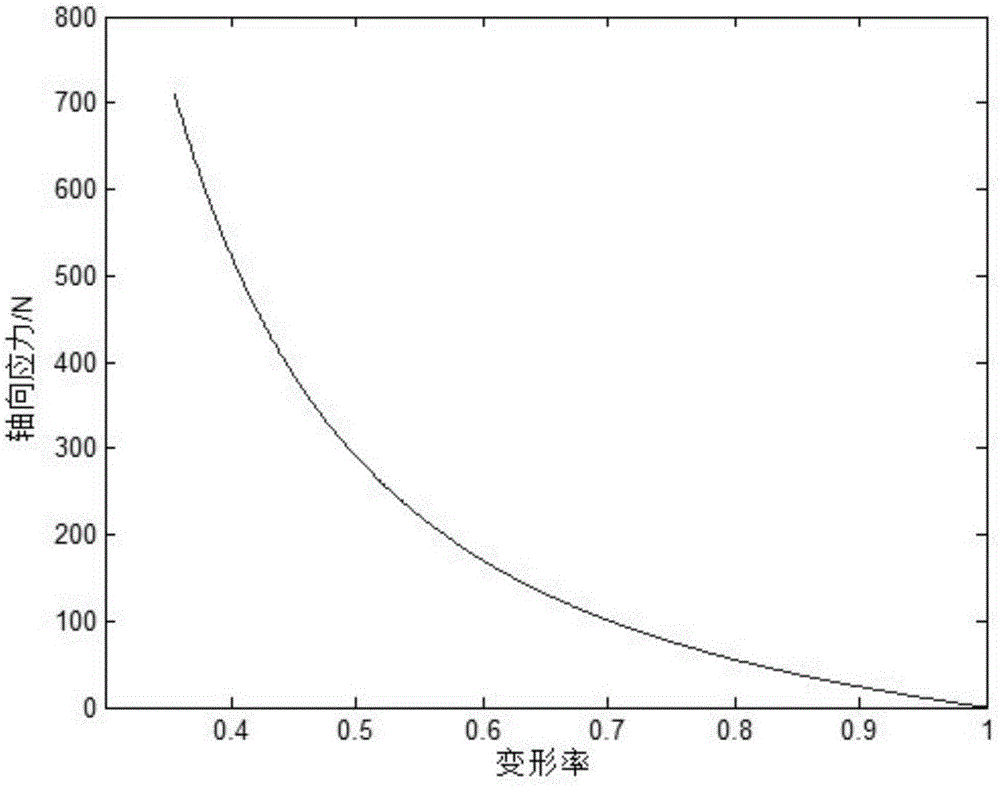

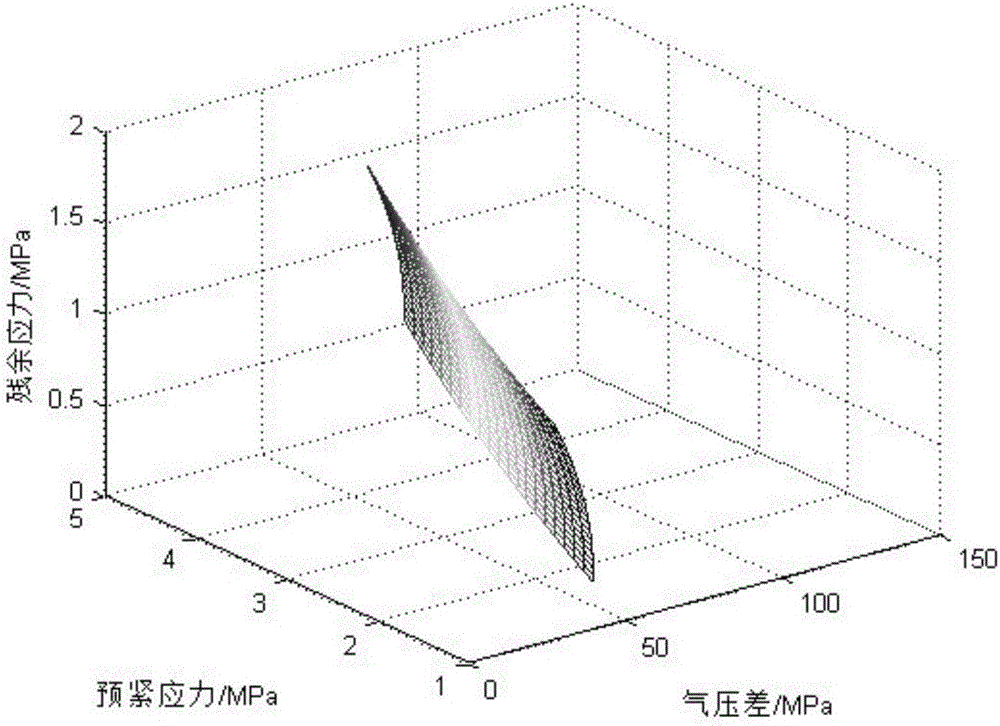

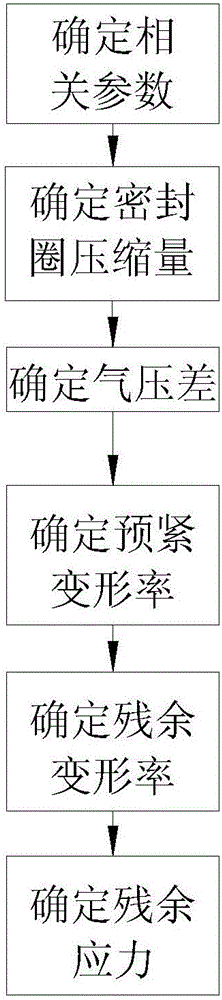

[0054] image 3It is a schematic flow chart of the method of the present invention. As shown in the figure, the implementation process of the method includes: (1) determining the relevant parameters of the solid rocket motor; (2) confirming the preload compression deformation of the sealing ring; (3) determining the Air pressure difference when the solid rocket motor works at high pressure; (4) Determine the deformation rate of the sealing ring in the pre-tightened state; (5) Solve the residual deformation rate of the sealing ring; (6) Solve the residual stress of the sealing ring.

[0055] (1) Determine the relevant parameters of the solid rocket motor

[0056] There are many model parameters to be determined in the present invention, mainly the structural material parameters of the solid rocket motor and the structural material parameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com