Automatic control system, method and device for combined harvester

A technology of combine harvester and control system, applied in the field of automatic control device and automatic control device, can solve the problems of unsafe, unable to open at the same time, starting with large engine load, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

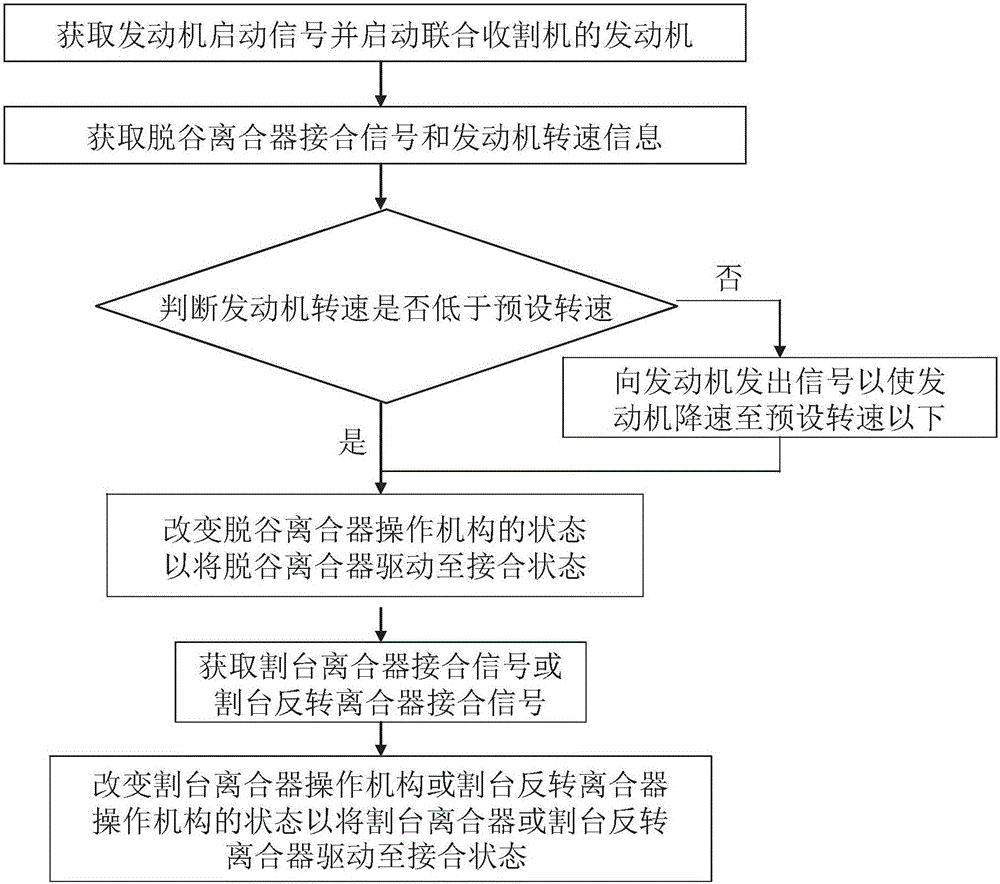

[0029] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

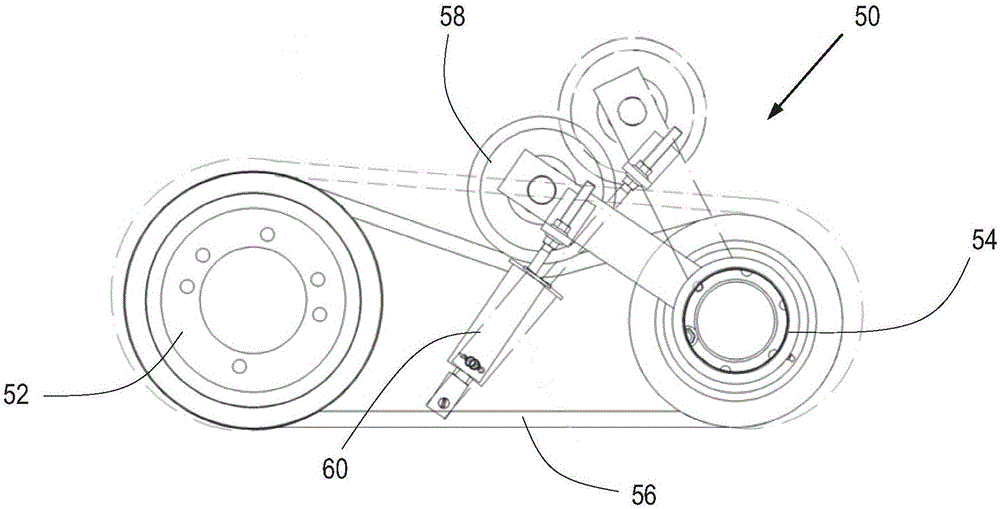

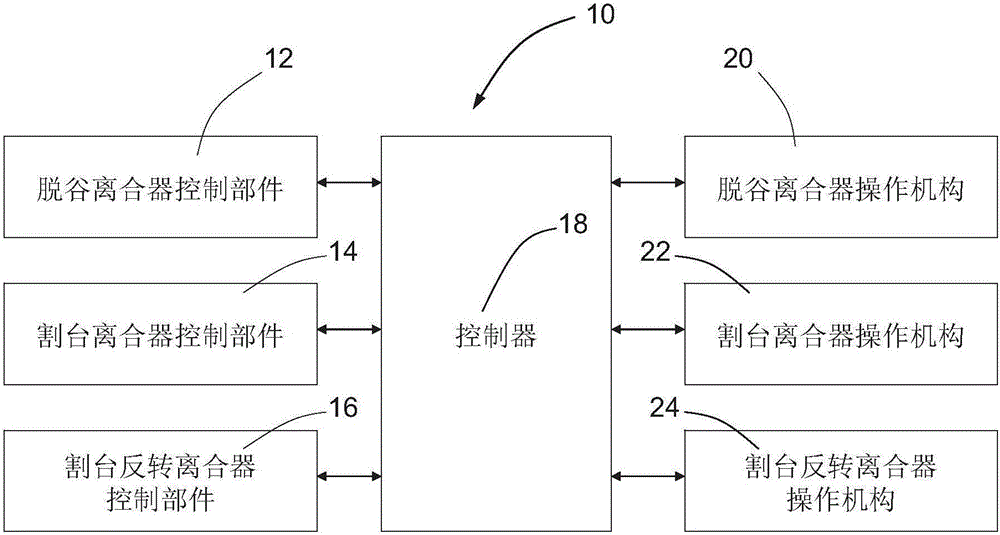

[0030] The present invention proposes a kind of automatic control system that is used for combine harvester, below at first referring to attached figure 1 A brief description will be given of a clutch for a combine harvester according to the present invention. Such as figure 1 As shown, the clutch 50 for the combine includes a driving wheel 52 coupled with the engine of the combine, a driven wheel 54 for driving a threshing device or header of the combine, and a driven wheel 54 arranged between the driving wheel 52 and the harvester. The belt 56 between the driven pulley 54 and the tensioning device that is arranged on the belt 56 so that the belt 56 is tensioned or loosened between the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com