Lag screw

A screw and tension technology, applied in the field of medical devices, can solve the problems of easily piercing the femoral head, and achieve the effect of firm and reliable fixation, stability and effectiveness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

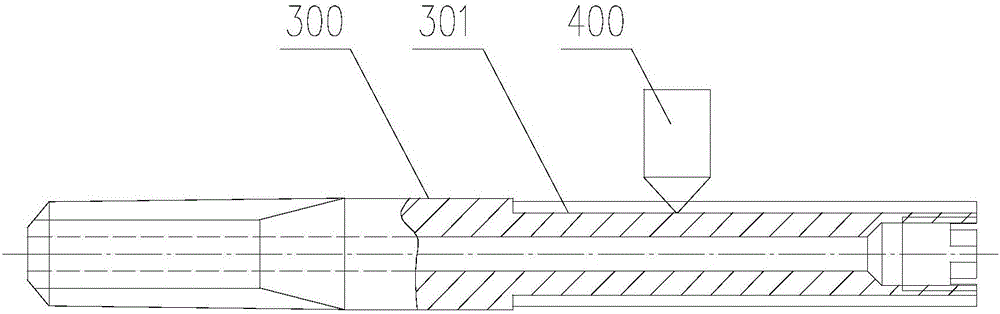

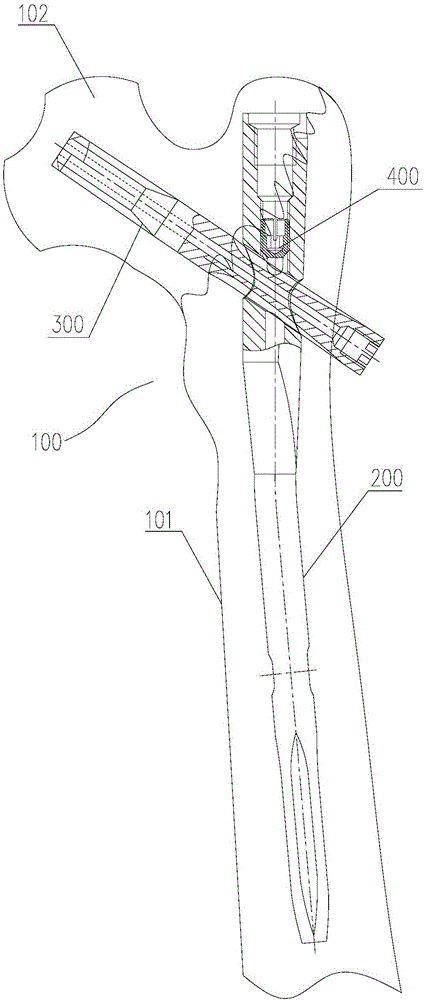

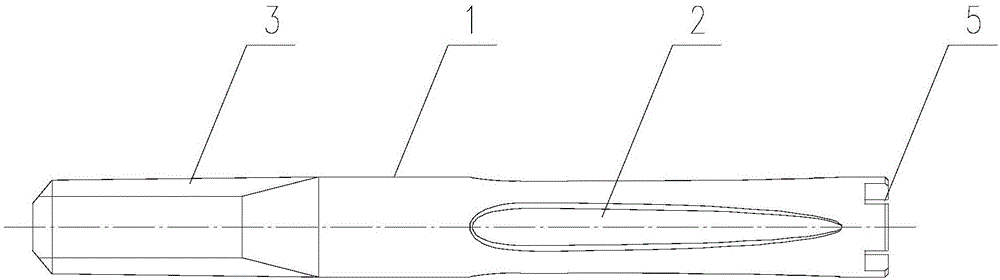

[0025] Such as figure 2 As shown, a lag screw assembly structure of the present invention includes a femur 100, an intramedullary nail 200, a lag screw 300 and a fastening screw 400, the intramedullary nail 200 penetrates the femoral body 101 of the femur 100 from top to bottom, and the lag screw 300 penetrates the intramedullary nail 200 along the direction of the femoral head 102, the fastening screw 400 is placed in the inner hole of the intramedullary nail 200, and is threadedly connected with the intramedullary nail 200, and the spherical head of the fastening screw 400 is embedded in the lag screw 300 The anti-rotation groove 2 is in contact with the anti-rotation groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com