Preparation method of high-performance sealing material applied to high-temperature environment

A sealing material, high temperature environment technology, applied in the field of high-performance sealing material preparation, can solve the problems of inconvenient operation of the pressing plate, affecting the quality of the sealing parts, etc., and achieve the effect of improving product quality and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

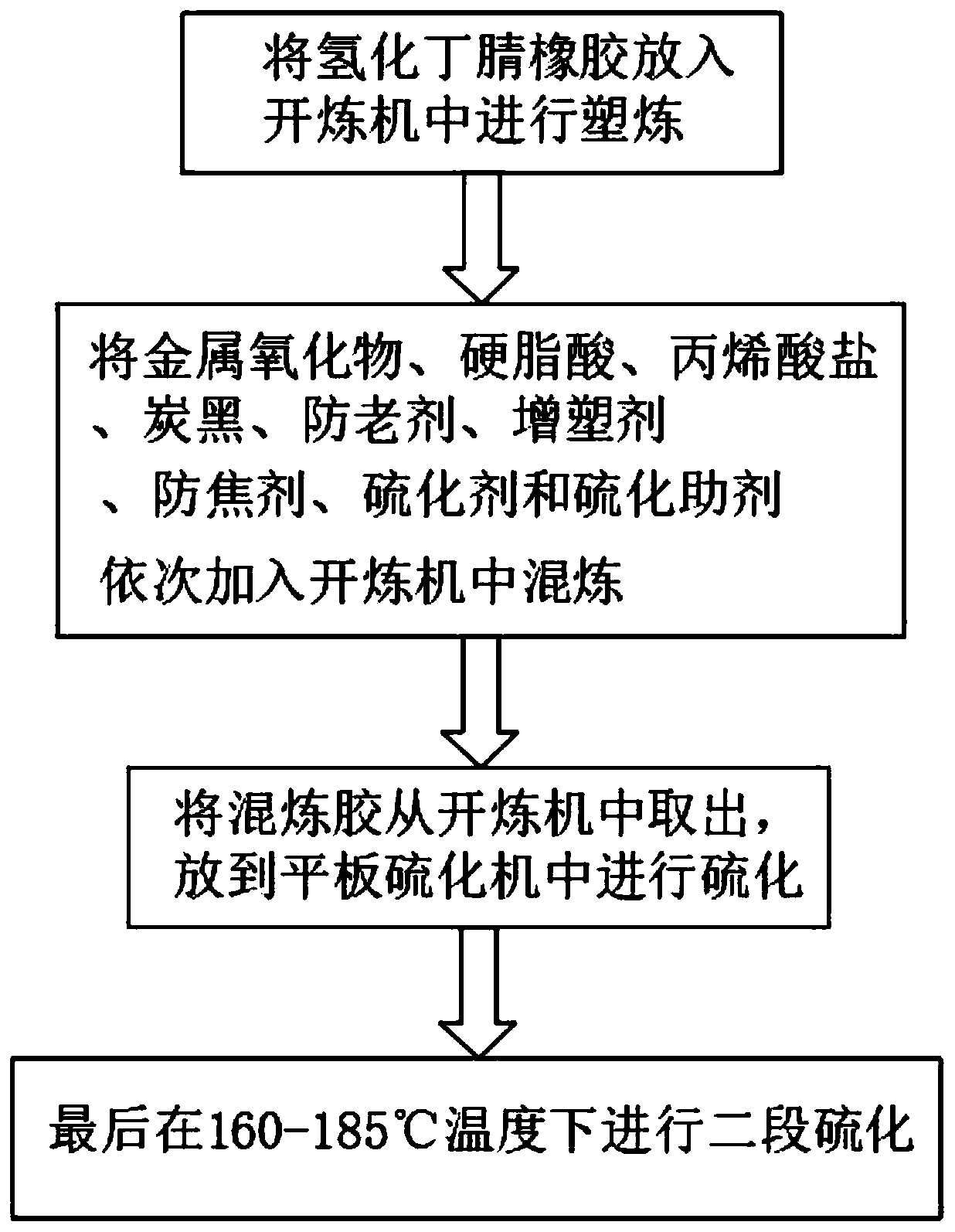

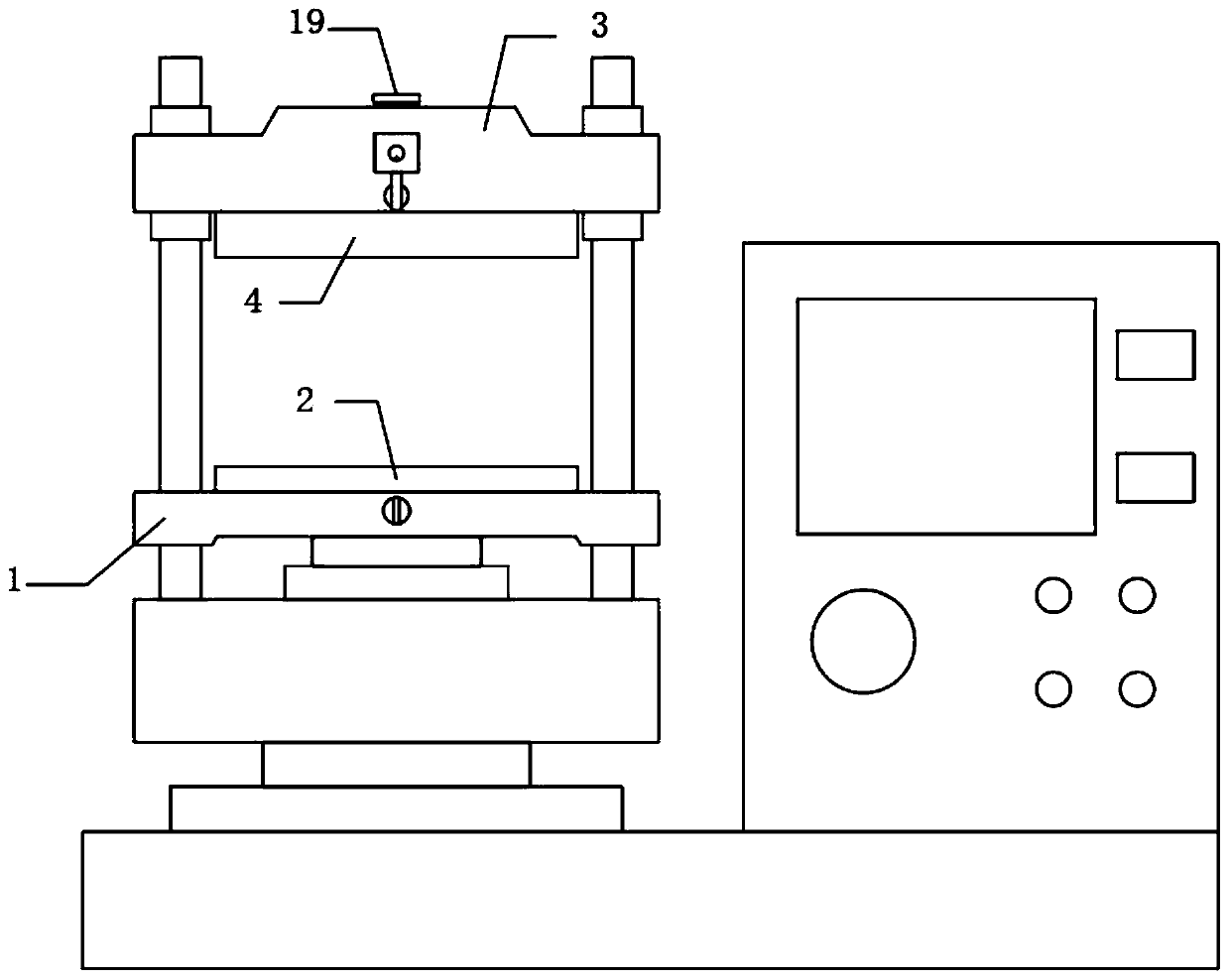

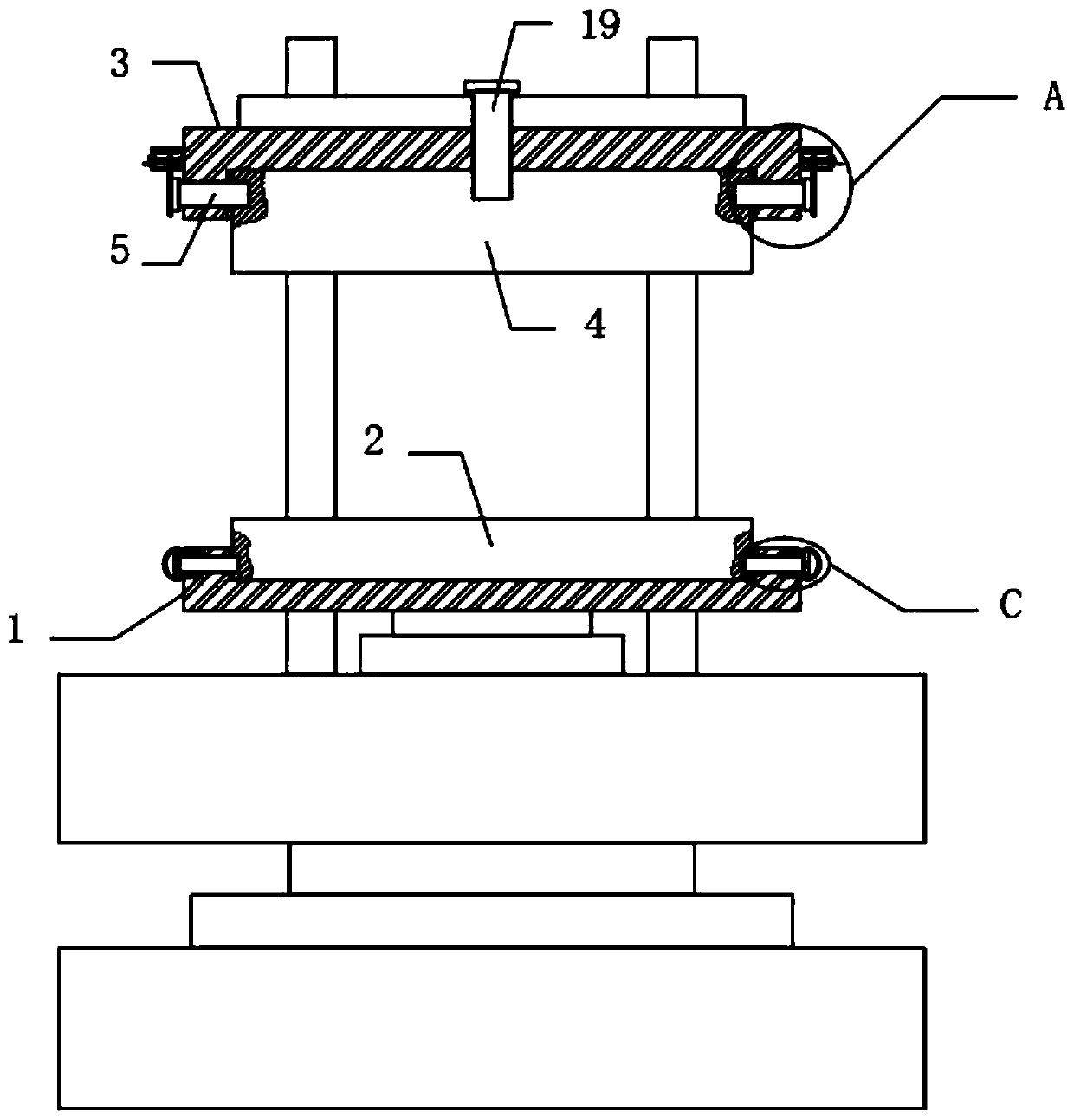

[0045] see figure 1 , a method for preparing a high-performance sealing material applied in a high-temperature environment, comprising the following steps:

[0046] S1, putting the hydrogenated nitrile rubber into an open mill for masticating;

[0047] S2, then adding metal oxide, stearic acid, acrylate, carbon black, anti-aging agent, plasticizer, anti-scorch agent, vulcanizing agent and vulcanization auxiliary agent into the open mill and kneading evenly to obtain a rubber compound;

[0048] S3, taking out the mixed rubber from the open mill, and putting it into a flat vulcanizer for vulcanization;

[0049] S4, and finally perform two-stage vulcanization.

[0050] The formula of each material in the S2 step is: hydrogenated nitrile rubber: 100 parts, metal oxide: 2-18 parts, stearic acid: 1-6 parts, acrylate: 6-90 parts, carbon black: 12-68 parts , anti-aging agent: 2-4 parts, plasticizer: 4-32 parts, anti-scorch agent: 3-9 parts, vulcanizing agent: 3-10 parts, vulcanizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com