Pull rod and rod pulling machine with the same

A tie rod and core rod technology, which is applied in the assembly of fuel elements, reactor fuel elements, nuclear power generation, etc., can solve the problems of low efficiency and high labor intensity, and achieve the effect of high operation efficiency, low labor intensity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

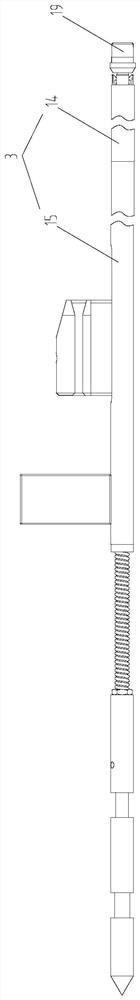

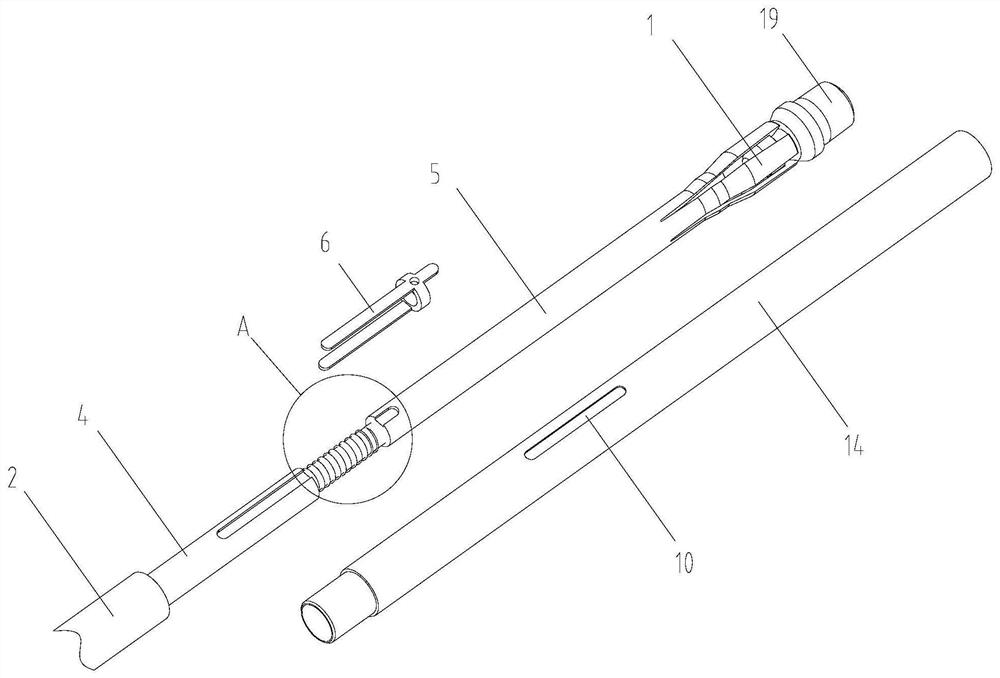

[0040] This embodiment provides a pull rod, such as figure 1 - Figure 5 As shown, it includes: pull claw 1, core rod 2 and adjustment mechanism, pull claw 1 is used to grab fuel rods, pull claw 1 and core rod 2 are connected through an adjustment mechanism, and the adjustment mechanism is suitable for adjusting pull claw 1 and core rod 2 The pull rod also includes a pipe fitting 3, the core rod 2 is set in the pipe fitting 3, one end of the pipe fitting 3 is against the pull claw 1, and the pull claw 1 is suitable for entering or exiting one end of the pipe fitting 3.

[0041] Wherein, the pipe fitting 3 comprises a clamping tube 14 and a sleeve tube 15 clamped with the clamping tube 14, the clamping tube 14 is arranged between the sleeve tube 15 and the pull claw 1, and the adjustment mechanism is located in the clamping tube 14, and the axial dimension of the clamping tube 14 is smaller than the sleeve 15; it should be noted that in this embodiment, the specific structure of...

Embodiment 2

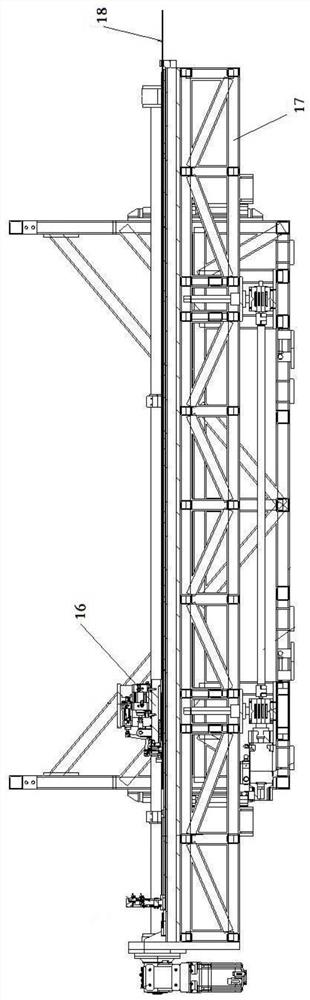

[0060] The rod drawing machine of the present embodiment, as figure 1 As shown, it includes the pull rod described in Embodiment 1, and also includes a slide mechanism 16 and an installation platform 17, and the pull rod 18 is arranged between the slide mechanism and the installation platform 17. Since the pull rod 18 is provided with an adjustment mechanism, the distance between the pull claw 1 and the core rod 2 is shortened or extended by the adjustment mechanism, and then the length of the pull claw 1 extending out of the pipe 3 is adjusted, so that each pull rod can be connected to the end plug of the fuel rod. 19 snap-in, and snap-in at the correct position.

[0061] Compared with the traditional rod pulling machine, which manually moves the fuel rod to connect the fuel rod end plug 19 to the tie rod, the rod pulling machine in this embodiment can greatly save manpower, has low labor intensity, and has higher working efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com