Pressure testing type numerically-controlled crusher for solid wastes

A technology of solid waste and testing pressure, applied in grain processing and other directions, can solve the problems of low degree of automation, waste of time, restricting the processing speed of equipment, etc., to improve the economic efficiency of enterprises, increase the operating life and reduce the frequency of maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

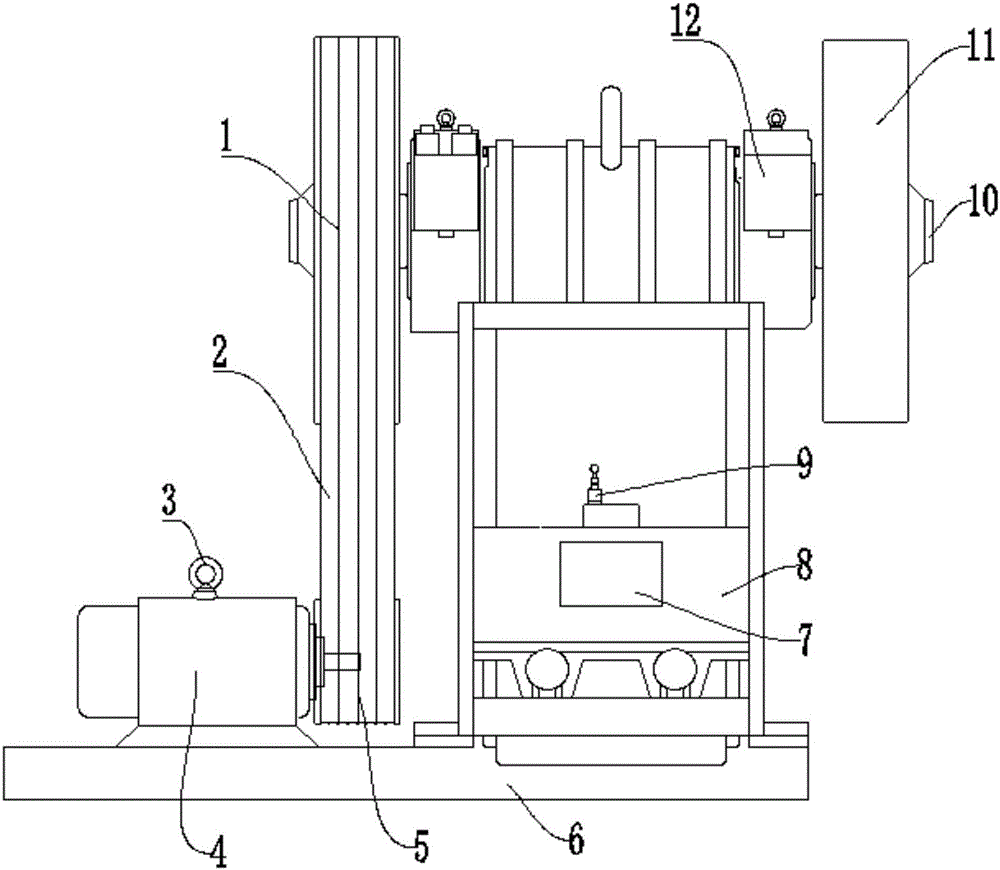

[0015] like figure 1 As shown, a kind of numerically controlled crushing machine for solid waste that can test the pressure includes a motor 4, a base plate 6, a numerical control panel 7 and a pressure sensor 9, a motor 4 is arranged on the upper surface of the base plate 6, and the motor 4 is used to provide power for the crusher. A hoisting ring 3 is arranged next to the 4, and the hoisting ring 3 is used to move the motor 4. A driving wheel 5 is arranged next to the hoisting ring 3, and the driving wheel 5 is used to transmit power to the conveyor belt 2. A conveyor belt 2 is arranged next to the driving wheel 5. The conveyor belt 2 is used to transmit the power to the driven wheel 1. The driven wheel 1 is arranged beside the conveyor belt 2. The driven wheel 1 is used to transmit the power to the main shaft 10. For crushing, a reduction box 12 is arranged next to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com