Multi-pipe type centrifugal solid-liquid separation machine

A solid-liquid separator and multi-tube technology, which is applied in centrifuges and other directions, can solve the problems of difficult control of revolution speed and rotation speed, short life of rotation drive belt, and difficult maintenance of filter cartridge bearings, etc., so as to achieve easy control of rotation speed, The effect of large driving torque and easy maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

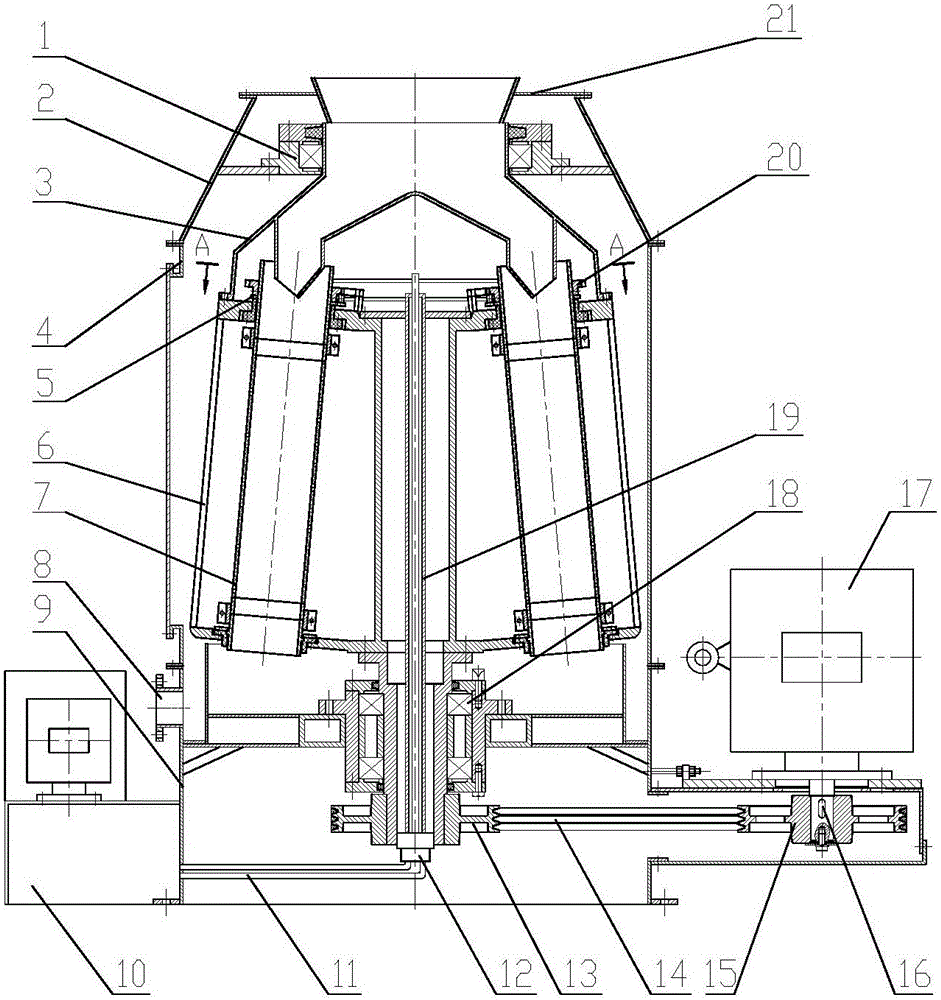

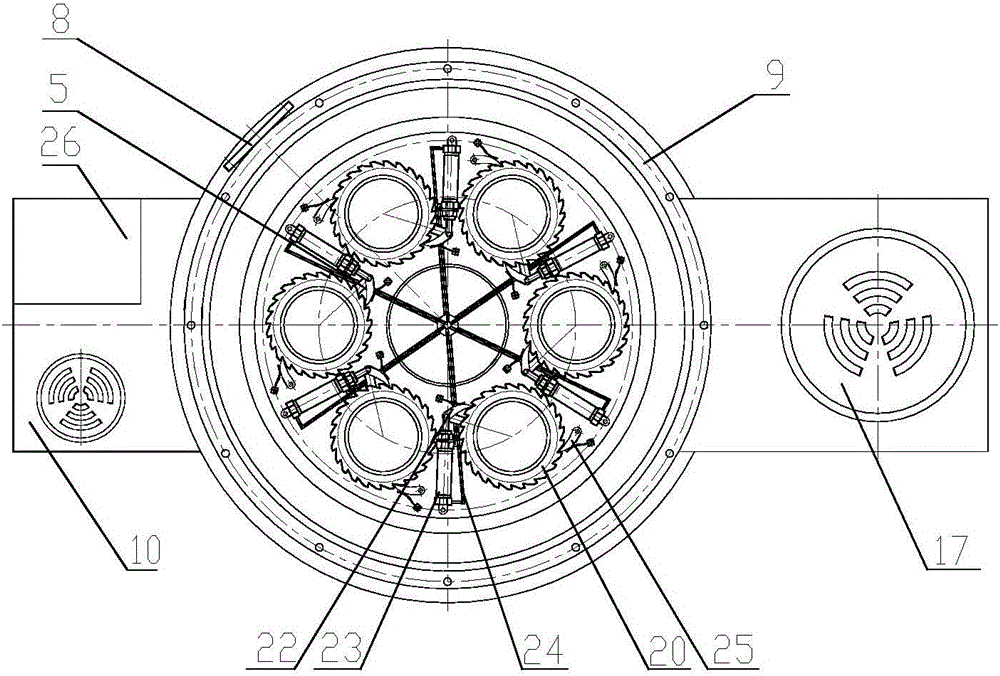

[0037] Below with reference to accompanying drawing, further describe:

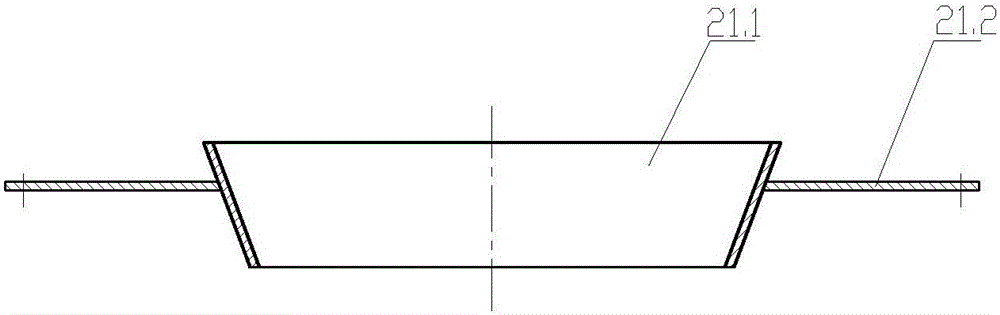

[0038] According to the present invention, if Figure 1 ~ Figure 2 As shown, 1 is the top bearing assembly, 2 is the upper cone shell, 3 is the dynamic inlet, 4 is the main shell, 5 is the driving handle, 6 is the drum assembly, 7 is the filter cartridge, 8 is the liquid outlet , 9 is the skirt seat, 10 is the hydraulic station, 11 is the main oil pipe, 12 is the dynamic and static joint, 13 is the slave pulley, 14 is the belt, 15 is the main pulley, 16 is the key, 17 is the main motor, 18 is the transmission assembly , 19 is the main oil pipe assembly, 20 is a ratchet, 21 is a static feed inlet, 22 is a driving pawl, 23 is a hydraulic cylinder, 24 is an oil distribution pipe, 25 is a stop pawl, and 26 is a control box.

[0039] Such as Figure 1 ~ Figure 2 In the multi-tube centrifugal solid-liquid separator shown, the exterior is sequentially connected to the static feed inlet 21, the upper cone shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com