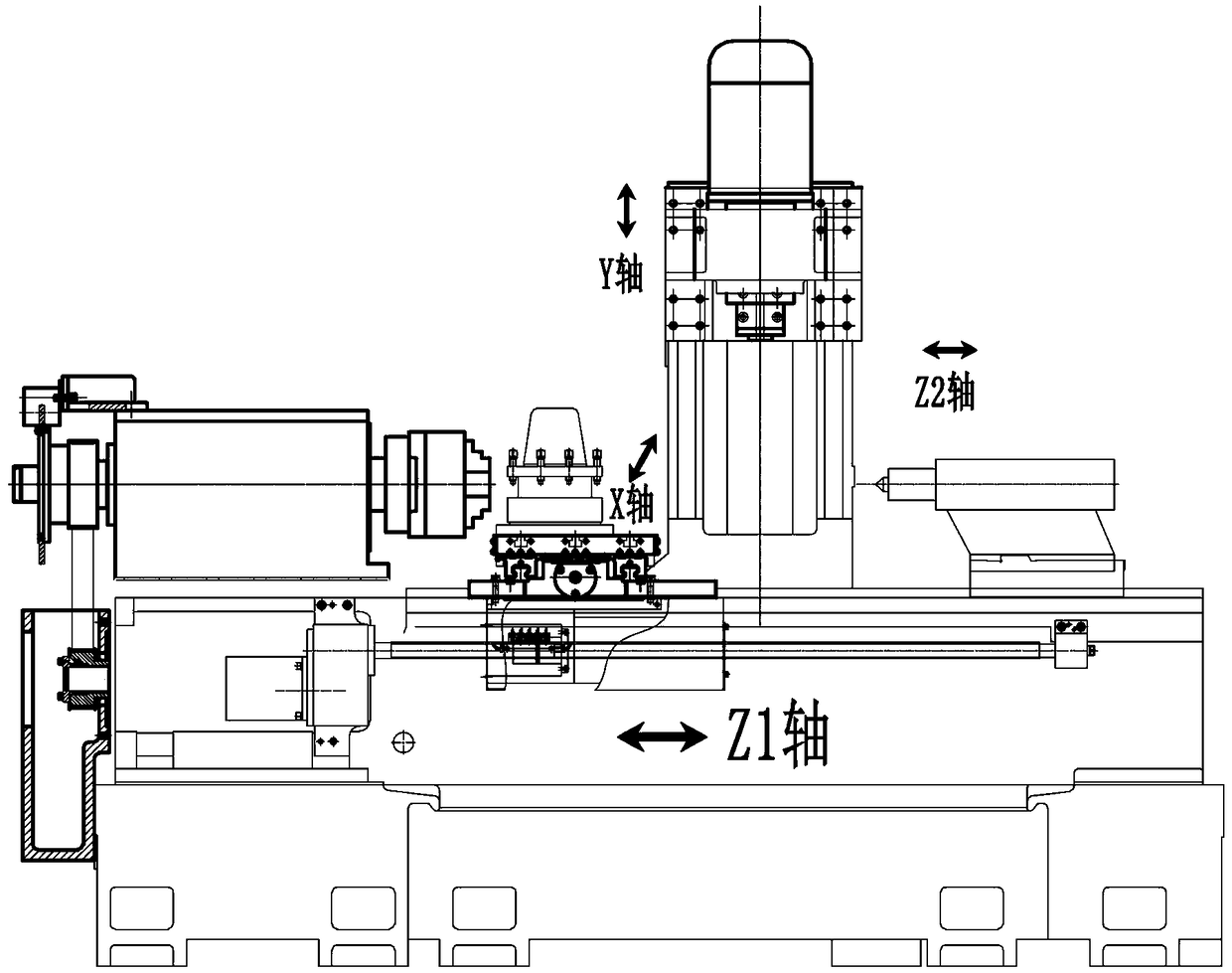

A Redundant Manual Control System for Turn-Mill Compound Machine Tool

A compound machine tool and redundant technology, applied in the direction of automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve problems such as machine tool failure, CNC system failure, and paralysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

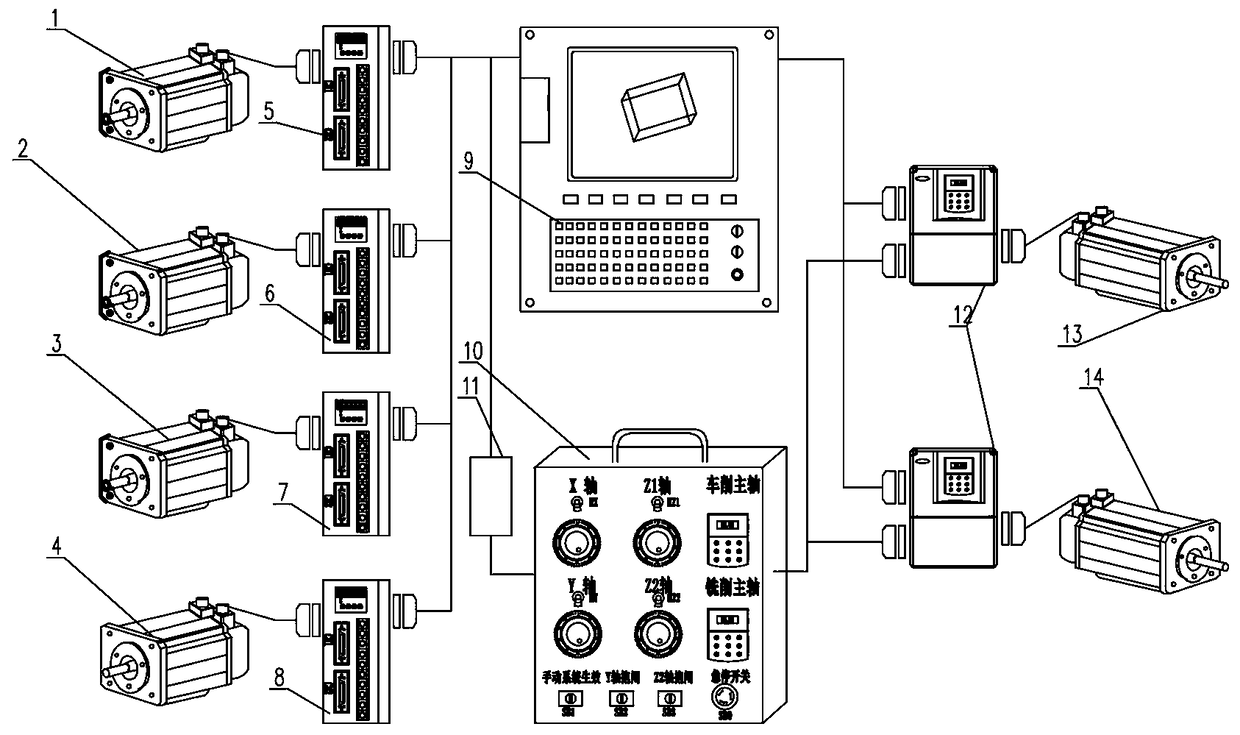

[0020] The specific implementation of the present invention will be further described below in conjunction with the schematic diagram of the control connection.

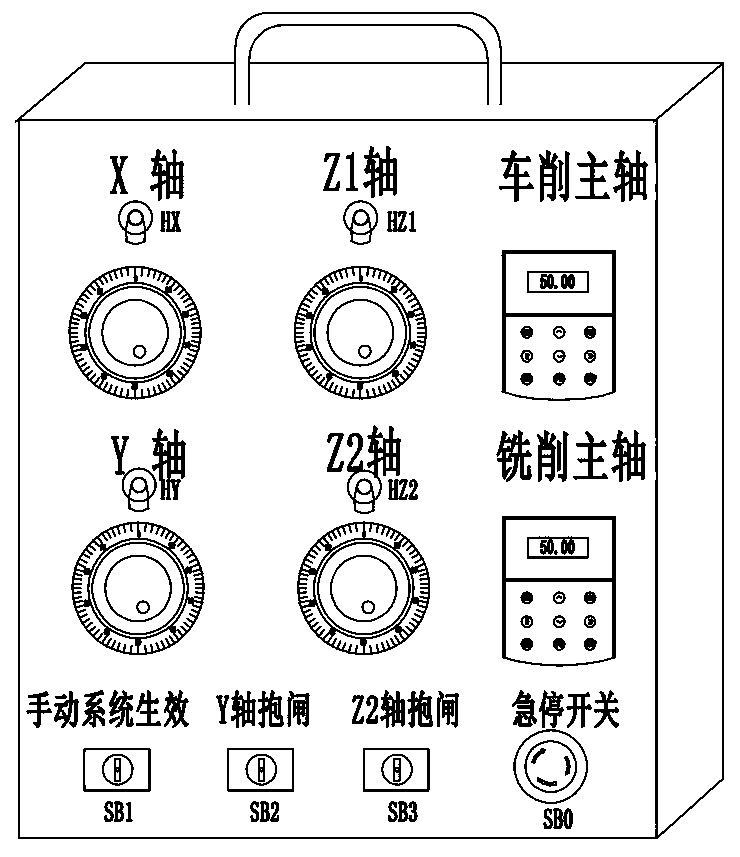

[0021] The following takes the feed axis X-axis as an example to describe in detail how the manual control device and the numerical control system can automatically switch between the main control and the redundant control. The detailed control connection diagram is as follows Figure 4 shown.

[0022] When the numerical control system breaks down or becomes paralyzed, it is only necessary to release the emergency stop switch SB0 on the "manual control system", and the system effective switch SB1 is turned ON, and the normally open contacts of relays KA1 and KA2 are energized and closed, and the operation is completed. The control process of switching from the CNC system mode to the redundant manual control mode is realized, and the redundant manual control system takes effect, thereby realizing the fast and effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com