Powder material cooling system and cooling process thereof

A powder material and cooling system technology, applied in heat exchange equipment, direct contact heat exchangers, fixed tubular conduit components, etc., can solve the problem of low control requirements, powder materials that do not have engineering feasibility, and are not easy to form Stable fluidized bed and other issues to achieve the effect of low control requirements, improved cooling effect, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

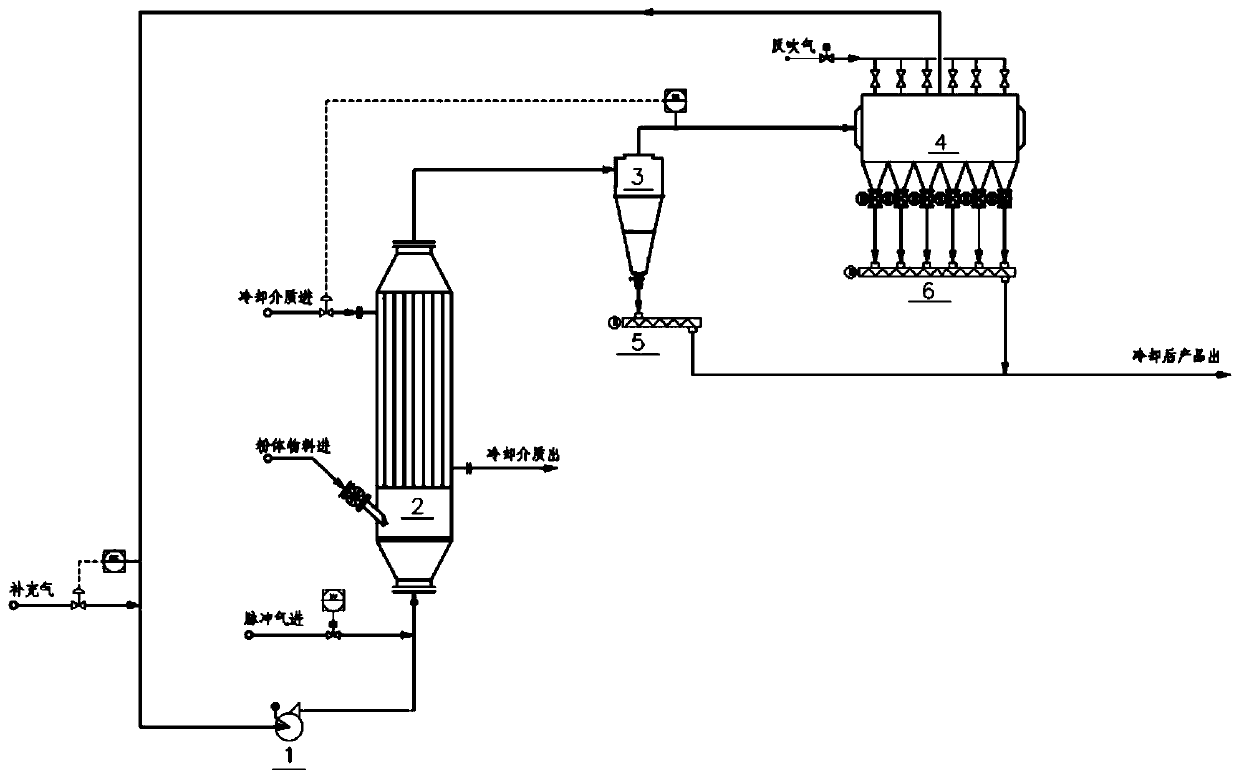

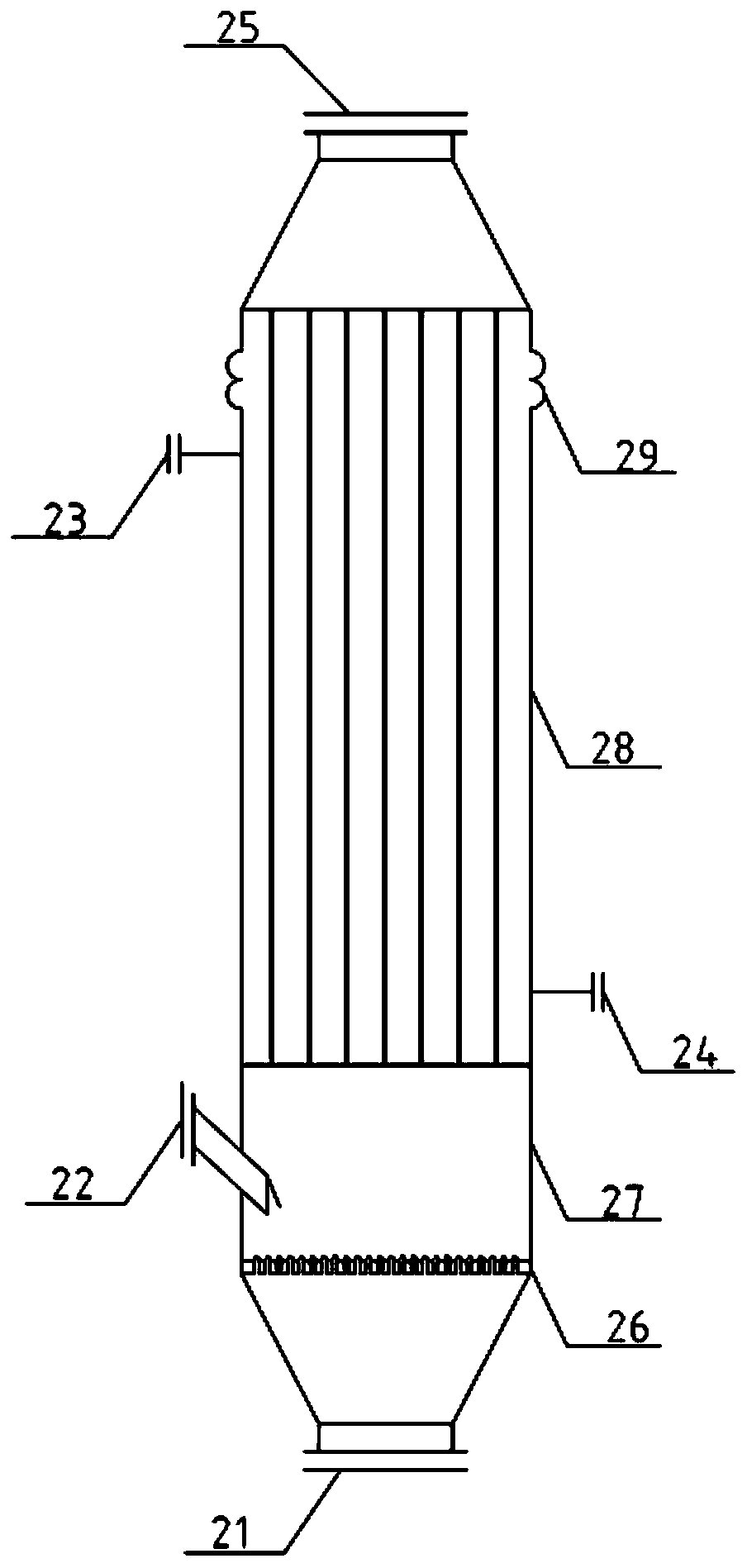

[0042] The embodiment is basically as figure 1 with figure 2 Shown: This embodiment provides a cooling system for powder materials, which can be used in the fields of chemical engineering, inorganic salt industry, metal oxide, metal powder production, etc. Moist or perishable, poor fluidity powder materials have poor cooling effect and are not suitable for engineering implementation, which has good practicability; specifically, such as figure 1 As shown, the cooling system includes a circulating fan 1, a powder fluidized cooler, a cyclone separator 3, a bag filter and a powder conveyor; wherein, the powder fluidized cooler is vertically installed, and the powder fluidized cooling The lower end of the device is provided with a powder material inlet 22, and its top outlet 25 is connected with the inlet of the cyclone separator 3, and the bottom gas inlet 21 of the powder fluidized cooler is connected with the outlet of the circulating fan 1, so that the gas-solid two-phase flo...

Embodiment 2

[0055] On the other hand, this embodiment also provides a cooling process of the powder material cooling system, using the above powder material cooling system, specifically including the steps of starting up and stopping:

[0056] Driving steps:

[0057] Step 1, open the air supply valve on the air supply pipeline, turn on the circulation fan 1, and replace the air in the cooling system; during this process, the circulation fan 1 operates at low load;

[0058] Step 2: Open the feed valve of the powder material inlet 22, and the powder material enters the fluidization chamber 27 of the powder fluidization cooler to form a stable fluidization state, so that the powder material is evenly distributed in the air distribution above plate 26;

[0059] Step 3: Increase the flow rate of the circulating fan 1 and increase the feeding amount of the powder material at the same time. Driven by the carrier gas, the powder material evenly enters the tube side of the shell-and-tube heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com