Character carving machine with paperweight

A paper presser and cutting plotter technology, applied in the field of plotters, can solve the problems of low efficiency, large energy loss, slow speed, etc., and achieve the effect of improving engraving accuracy, improving installation accuracy, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

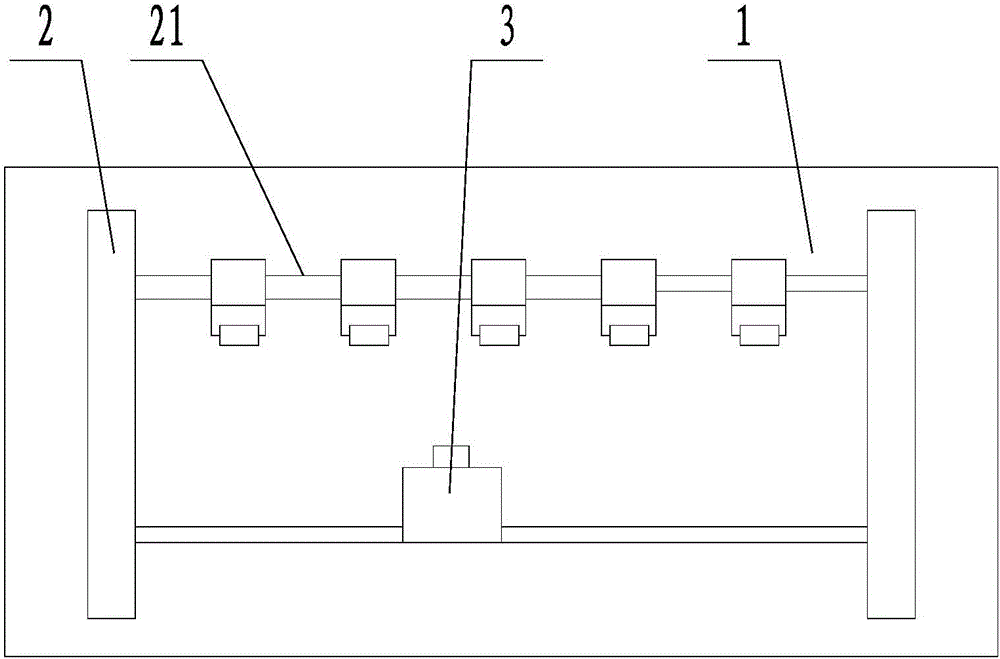

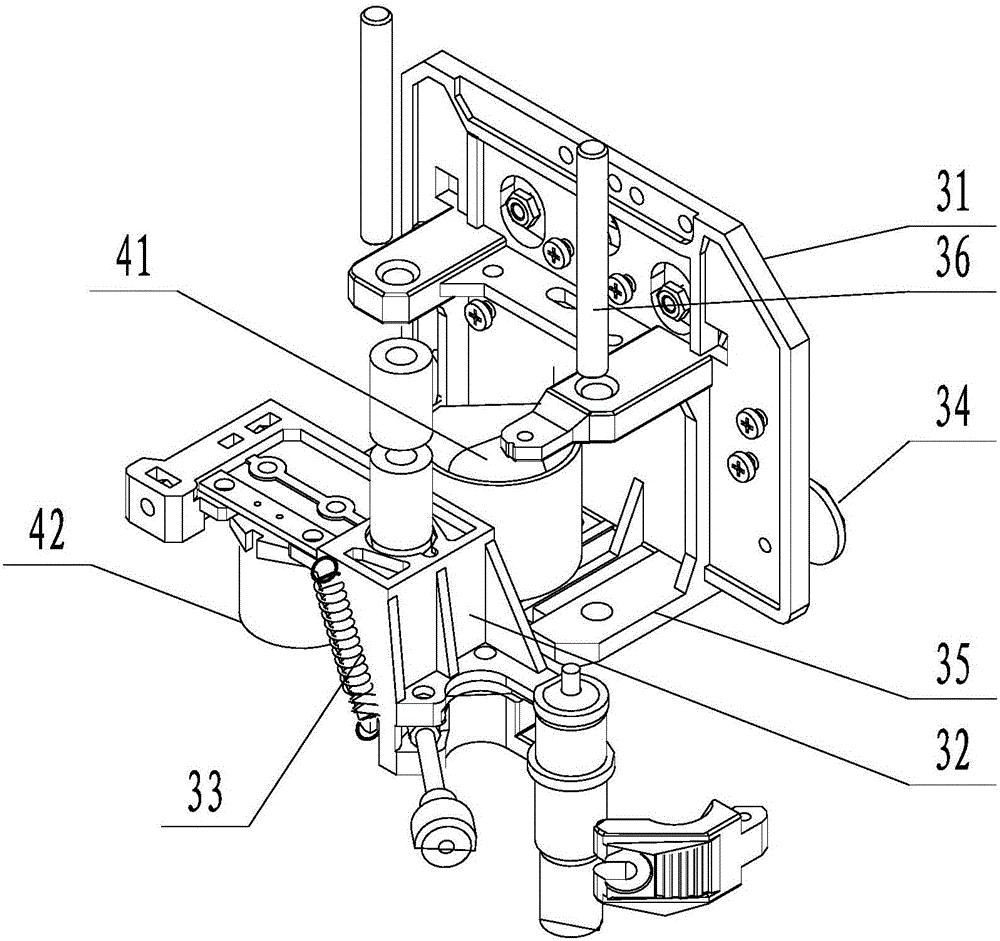

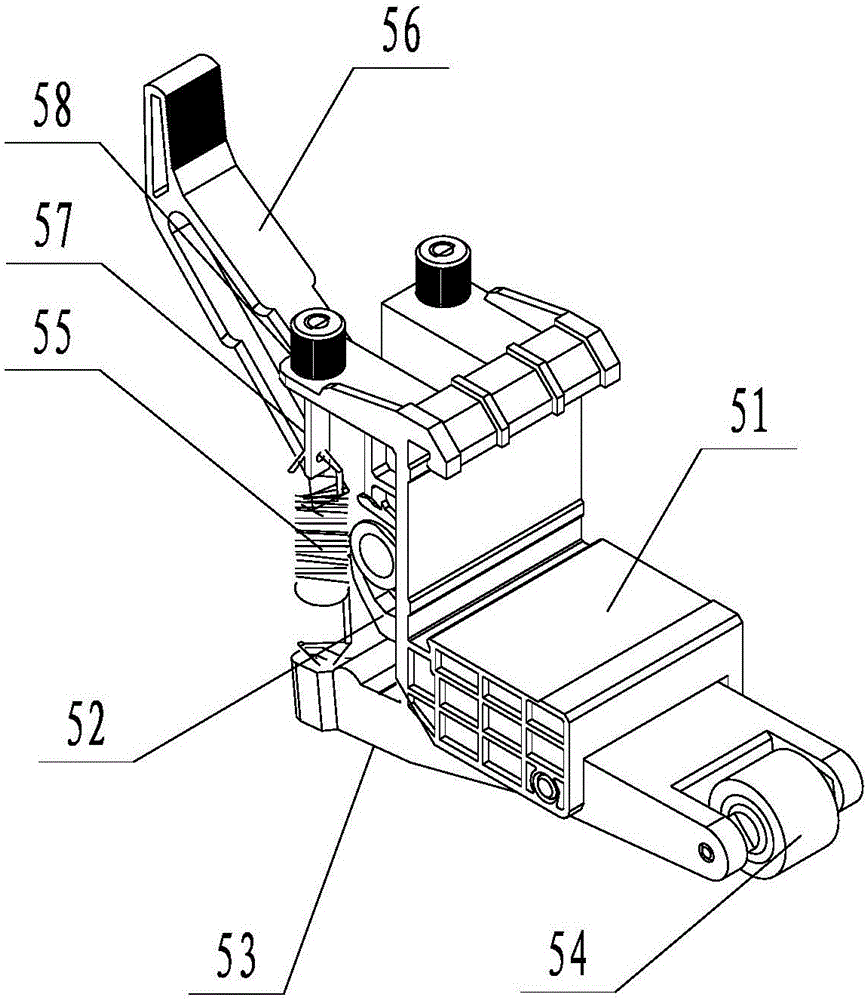

[0019] Such as Figures 1 to 3 as shown, figure 1 It is a structural schematic diagram of a cutting plotter with a paper presser proposed by the present invention, figure 2 It is a structural schematic diagram of a lettering device of a cutting lettering machine with a paper presser proposed by the present invention, image 3 It is a structural schematic diagram of a paper pressing mechanism of a cutting plotter with a paper pressing device proposed by the present invention.

[0020] refer to Figures 1 to 3 , a kind of cutting plotter with paper presser that the present invention proposes, comprises: base 1, support 2, carving knife device 3, paper presser, first drive unit, second drive unit:

[0021] The base 1 is provided with a backing plate and a slide rail, the slide rail is located on one side of the backing plate, the support 2 is located above the backing plate and is movably mounted on the slide rail, and the first driving device is connected to the support 2 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com