Car carpet with enhanced sound insulation

A car carpet and film layer technology, which is applied to vehicle parts, special positions of vehicles, synthetic resin layered products, etc., can solve the problems of not meeting the requirements of light weight of cars, poor sound insulation effect, high product weight, etc., and achieve good surface quality And machinery, excellent sound insulation effect, high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

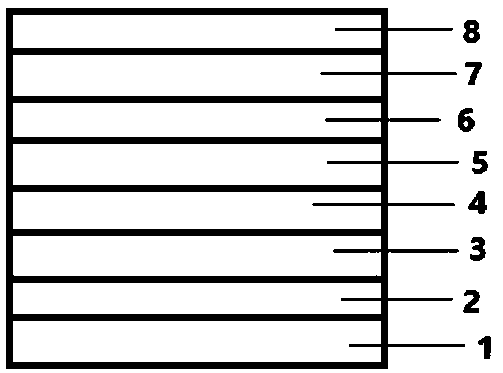

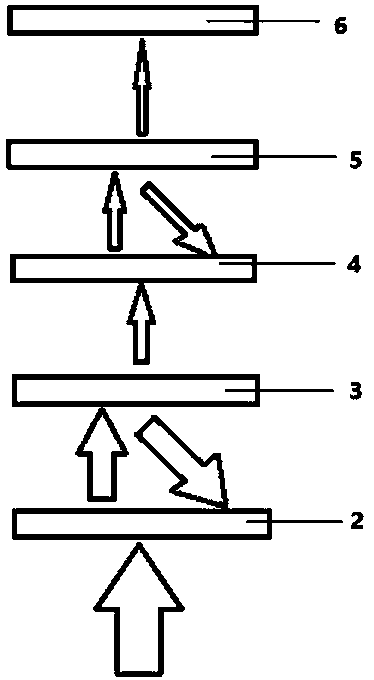

[0044] A car carpet for enhanced sound insulation, comprising a PET / PP composite layer (4), the PET / PP composite layer (4) comprising PET fibers in a weight ratio of 35 parts and PP fibers in a weight ratio of 25 parts, and the PET / PP The thickness of the composite layer (4) is 0.35 mm. The PET / PP composite layer (4) is conducive to molding and is the skeleton of the main carpet; the front side of the PET / PP composite layer (4) is provided with a PE film layer (5 ), the thickness of the PE film layer (5) is 0.15 mm, and the square gram weight of the PE film layer (5) is 150 g / m 2 , the PE film layer (5) mainly plays the role of sound insulation; the opposite side of the PET / PP composite layer (4) is provided with a PP film layer (3), and the PP film layer (3) mainly plays the role of sound insulation enhancement, so The thickness of the PP film layer (3) is 0.15 mm, and the square gram weight of the PP film layer (3) is 500 g / m 2 ; The front side of the PE film layer (5) is p...

Embodiment 2

[0068] A car carpet for enhanced sound insulation, comprising a PET / PP composite layer (4), the PET / PP composite layer (4) comprising 30 parts by weight of PET fibers and 20 parts by weight of PP fibers, the PET / PP The thickness of the composite layer (4) is 0.3 mm. The PET / PP composite layer (4) is conducive to molding and is the skeleton of the main carpet; the front side of the PET / PP composite layer (4) is provided with a PE film layer (5 ), the thickness of the PE film layer (5) is 0.2 mm, and the square gram weight of the PE film layer (5) is 180 g / m 2 , the PE film layer (5) mainly plays the role of sound insulation; the opposite side of the PET / PP composite layer (4) is provided with a PP film layer (3), and the PP film layer (3) mainly plays the role of sound insulation enhancement , the thickness of the PP film layer (3) is 0.2 mm, and the square gram weight of the PP film layer (3) is 450 g / m 2 ; The front side of the PE film layer (5) is provided with a PET fabric...

Embodiment 3

[0092] An automotive carpet for enhanced sound insulation, comprising a PET / PP composite layer (4), the PET / PP composite layer (4) comprising a weight ratio of 40 parts of PET fiber and 30 parts of PP fiber, the PET / PP The thickness of the composite layer (4) is 0.4 mm. The PET / PP composite layer (4) is conducive to molding and is the skeleton of the main carpet; the front side of the PET / PP composite layer (4) is provided with a PE film layer (5 ), the thickness of the PE film layer (5) is 0.1 mm, and the square gram weight of the PE film layer (5) is 120 g / m 2 , the PE film layer (5) mainly plays the role of sound insulation; the opposite side of the PET / PP composite layer (4) is provided with a PP film layer (3), and the PP film layer (3) mainly plays the role of sound insulation enhancement, so The thickness of the PP film layer (3) is 0.1 mm, and the square gram weight of the PP film layer (3) is 550 g / m 2 ; The front side of the PE film layer (5) is provided with a PET ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com