Portal frame system for automatic integral overturning conveyer

A flip-type, conveyor technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of lack of safety protection device, complex gantry structure, inability to automatically control, etc., to simplify the gantry structure, simplify the installation and positioning procedures, Improve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

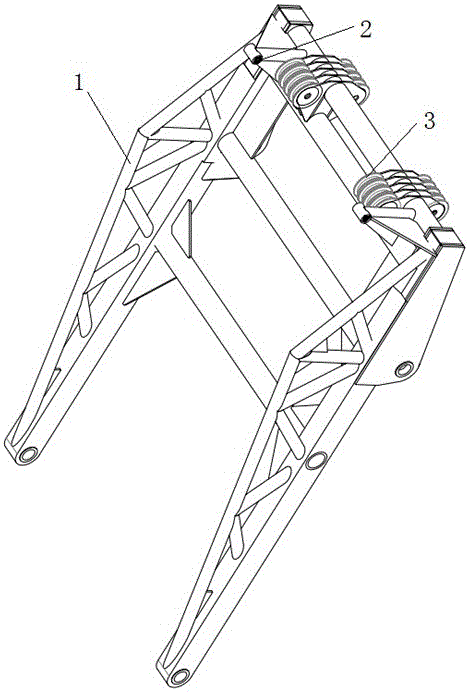

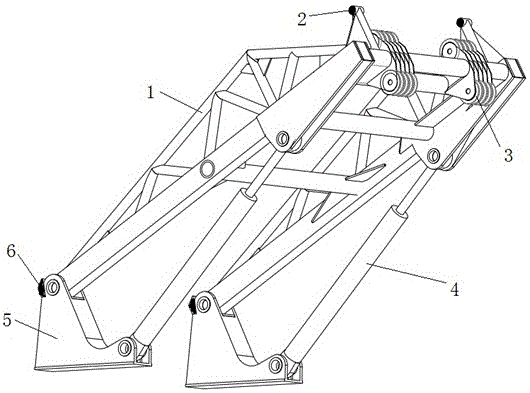

[0013] in the attached figure 1 Among them, the embodiments of the present invention are as follows. The present invention provides a gantry system for an automatic integral overturning conveyor, including a gantry (1), a pressure sensor (2), a pulley block (3), a hydraulic cylinder (4), a fixed Support (5), limit device (6).

[0014] in the attached figure 1 Among them, the fixed support (5) described in the embodiment of the present invention has two through holes for hinges. In order to ensure that the gantry (1) can achieve a large amplitude change from 0 degrees to 100 degrees, the two holes are front and rear. The height is staggered, the low hinge hole is used to connect the oil cylinder, the high hinge hole is used to connect the gantry (1) column, and the limit device (6) is installed next to the high hole; the wear-resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com