A kind of manufacturing method of polygonal solid tire

A technology of a solid tire and a manufacturing method, applied in the field of tire manufacturing, can solve the problems of small contact area and the safety of operation cannot be effectively guaranteed, and achieves good running stability, elimination of hidden dangers of tire puncture, and high puncture resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

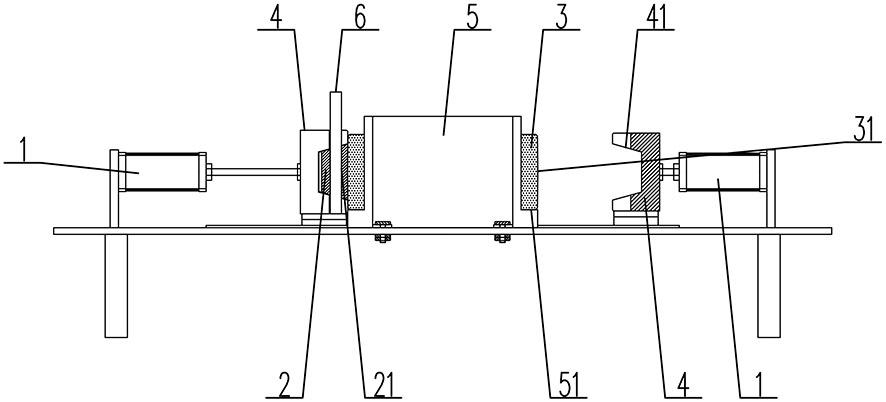

[0044] A method for manufacturing a polygonal solid tire, comprising the following steps:

[0045] (1) Take a rubber material A, extrude the rubber material A through an extruder and cut it to form a straight rubber strip;

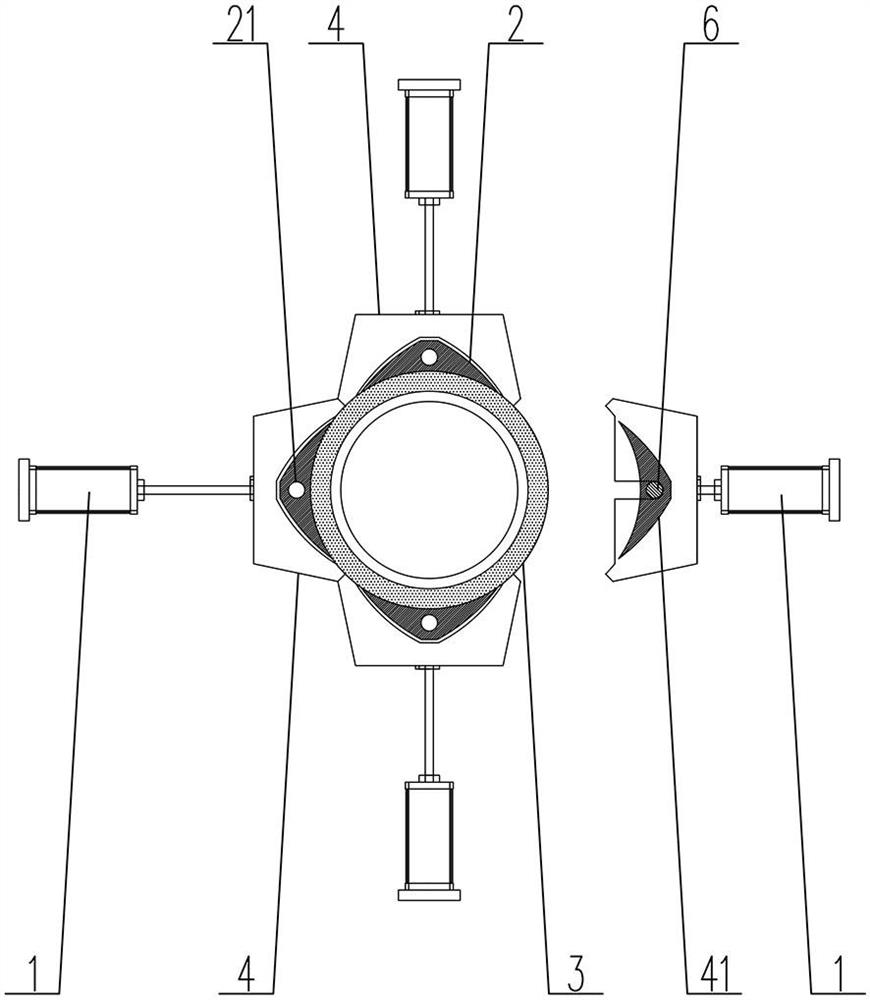

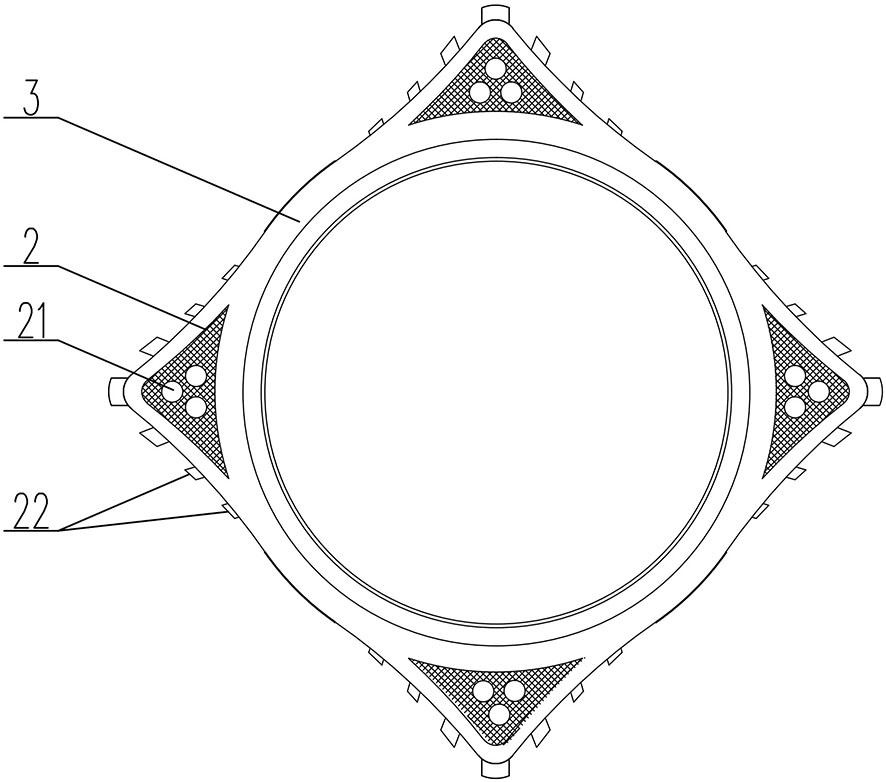

[0046] (2) Take a rubber material B, extrude the rubber material B through an extruder into a rubber strip with a buffer cooling hole 21 and a triangular cross-section, and cut it to form a convex rubber strip 2;

[0047] (3) Take the pins 6 with the same diameter as the buffer cooling holes 21 and insert each pin 6 into the corresponding buffer cooling holes 21 of the flange strip 2;

[0048] (4) Take at least three chime strips 2 with pins 6 and transfer them to the positioning grooves 41 on the chime strip positioning device 4 ;

[0049] (5) Take the straight rubber strip prepared in step (1) and coil the straight rubber strip along the outer surface of the green tire positioning device 5 to form the main body part 3 of the green tire;

[0050](6) The...

Embodiment 2

[0067] As a preference, the rubber material A in the step (1) and the rubber material B in the step (2) include the following composition by weight:

[0068] rubber 35,

[0069] carbon black 30,

[0070] operating oil 8,

[0071] staple fiber 5,

[0072] Adhesive 3,

[0073] Additive 2;

[0074] The preparation steps are as follows:

[0075] The materials of the above weight components were weighed, and then mixed and put into an internal mixer for mixing, wherein the pressure of the upper ram was 6kgf / cm2, the mixing time was 6 minutes, and the mixing temperature was 120°C. All the other implementation steps are the same as in Example 1.

Embodiment 3

[0077] As a preference, the rubber material A in the step (1) and the rubber material B in the step (2) include the following composition by weight:

[0078] rubber 45,

[0079] carbon black 35,

[0080] Operating oil 12,

[0081] staple fiber 10,

[0082] Adhesive 5,

[0083] Additive 3;

[0084] The preparation steps are as follows:

[0085] The materials of the above weight components were weighed, then mixed and put into an internal mixer for mixing, wherein the pressure of the upper ram was 8kgf / cm2, the mixing time was 8 minutes, and the mixing temperature was 140°C. All the other implementation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com