A kind of hydrophilic self-lubricating microsphere and its preparation method and application

A self-lubricating, microsphere technology, applied in the coating and other directions, can solve the problems of the use of filling materials, too large scale, etc., and achieve the effect of controllable size, controllable matrix size, and wide trial area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing hydrophilic self-lubricating microspheres, the method steps are as follows:

[0040] Step 1: Add emulsifier, buffer, 1 / 2 styrene monomer and acrylamide monomer into a three-necked flask equipped with a thermometer and a reflux condenser, dissolve in water, and wait until the emulsifier is completely dissolved;

[0041] Step 2: Dissolve the initiator in water at the same time, pour half of the dissolved solution into the reaction three-necked flask, stir, heat up to the specified temperature, and then drop the remaining styrene and acrylamide monomers;

[0042] Step 3: After the addition, add the remaining initiator into the reaction three-necked flask, heat to reflux temperature, and after the reaction is completed, cool to 50°C to complete the synthesis process, and obtain the styrene-acrylamide copolymerized microsphere dispersion;

[0043] Step 4: At the same time, disperse the sulfonated graphene in water to prepare a sulfonated graphene dispe...

Embodiment 1

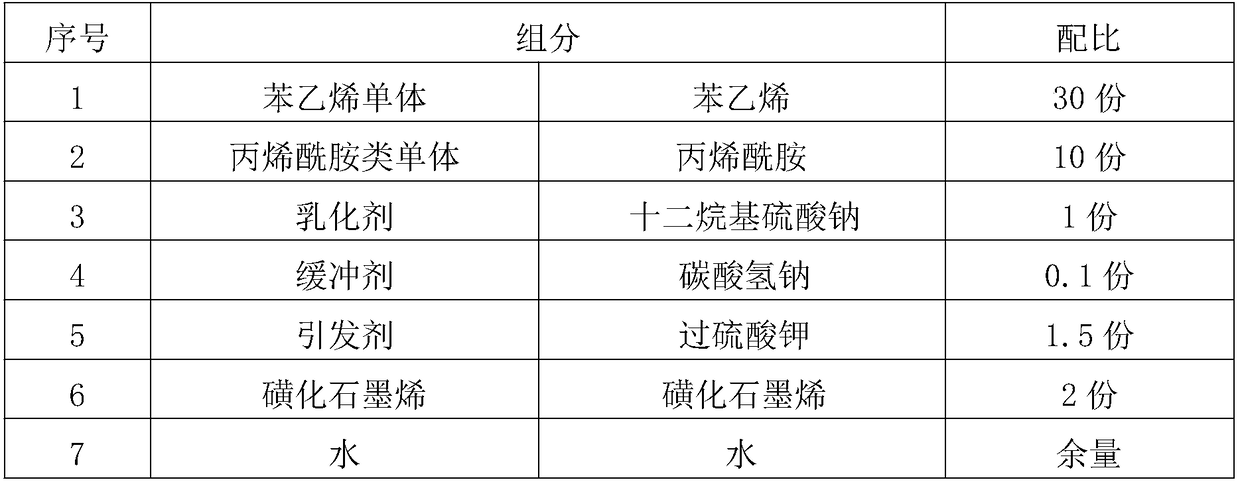

[0060] The ratio of various ingredients is as follows:

[0061]

[0062] (1) Add emulsifier, buffer, 1 / 2 styrene monomer and acrylamide monomer into a three-necked flask equipped with a thermometer and a reflux condenser, dissolve in water, and wait until the emulsifier is completely dissolved;

[0063] (2) Dissolve the initiator in water at the same time, pour half of the solution into the three-necked flask for reaction, stir at 300 rpm, heat to 60 degrees, and then drop the remaining styrene and acrylamide monomers;

[0064] (3) After the addition, add the remaining initiator into the reaction three-necked flask, heat to 80°C and reflux, and after the reaction is completed, cool to 50°C to complete the synthesis process, and obtain the dispersion of styrene-acrylamide copolymerized microspheres;

[0065] (4) At the same time, the sulfonated graphene is dispersed in water to prepare a sulfonated graphene dispersion with a concentration of 10%;

[0066] (5) After the styr...

Embodiment 2

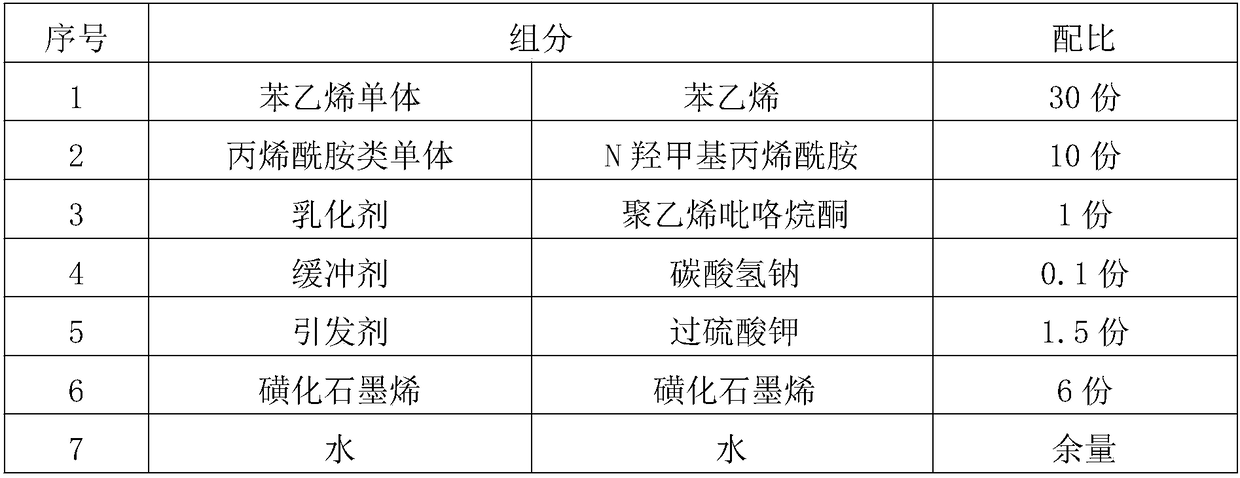

[0070] The ratio of various ingredients is as follows:

[0071]

[0072] (1) Add emulsifier, buffer, 1 / 2 styrene monomer and acrylamide monomer into a three-necked flask equipped with a thermometer and a reflux condenser, dissolve in water, and wait until the emulsifier is completely dissolved;

[0073] (2) Dissolve the initiator in water at the same time, pour half of the solution into the three-necked flask for reaction, stir at 300 rpm, heat to 60 degrees, and then drop the remaining styrene and acrylamide monomers;

[0074] (3) After the addition, add the remaining initiator into the reaction three-necked flask, heat to 80°C and reflux, and after the reaction is completed, cool to 50°C to complete the synthesis process, and obtain the dispersion of styrene-acrylamide copolymerized microspheres;

[0075] (4) At the same time, the sulfonated graphene is dispersed in water to prepare a sulfonated graphene dispersion with a concentration of 10%;

[0076] (5) After the styr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com