Luminescent PLA wire used for 3D printing, and preparation method thereof

A 3D printing and wire technology, applied in the field of 3D printing, to achieve the effect of simple preparation process and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

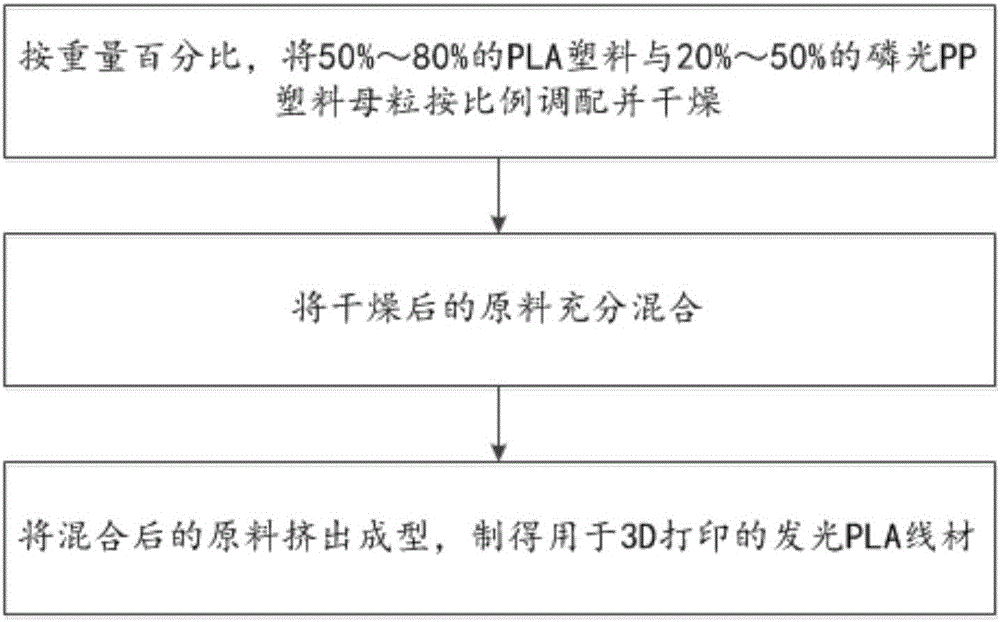

[0025] like figure 1 Shown, a kind of preparation method for the luminous PLA wire rod of 3D printing comprises the steps:

[0026] Step 1. According to the percentage by weight, 50% to 80% of PLA plastics and 20% to 50% of phosphorescent PP plastic masterbatches are blended in proportion, and the blended raw materials are placed in a closed environment at 90°C for 7 to 9 hours. dry;

[0027] Step 2, the dried raw materials are placed in a double-shaft blade mixer and fully mixed;

[0028] Step 3, extruding the mixed raw materials through a single-screw extruder to obtain the luminescent PLA wire for 3D printing, wherein the extrusion temperature is set at 195-210°C, and the speed of the single-screw extruder is 20 ~40rpm.

Embodiment 1

[0029] Example 1, blending 80% PLA plastic and 20% phosphorescent PP plastic masterbatch, using the above-mentioned preparation method for luminescent PLA wire for 3D printing, to prepare the luminescent PLA wire for 3D printing.

Embodiment 2

[0030] Example 2, blending 70% PLA plastic and 30% phosphorescent PP plastic masterbatch, using the above-mentioned preparation method for 3D printing luminescent PLA filament, to prepare the luminescent PLA filament for 3D printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com