Antibacterial anti-mite function filling non-woven fabric and manufacturing method thereof

A technology of non-woven fabrics and melt-blown non-woven fabrics, which is applied in the field of non-woven fabrics, can solve the problems of not being able to meet high heat retention and high elasticity at the same time, improve product quality and service life, avoid separation of fiber web layers, and enhance strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of the above-mentioned antibacterial and anti-mite function filled non-woven fabric, the method comprises the following steps:

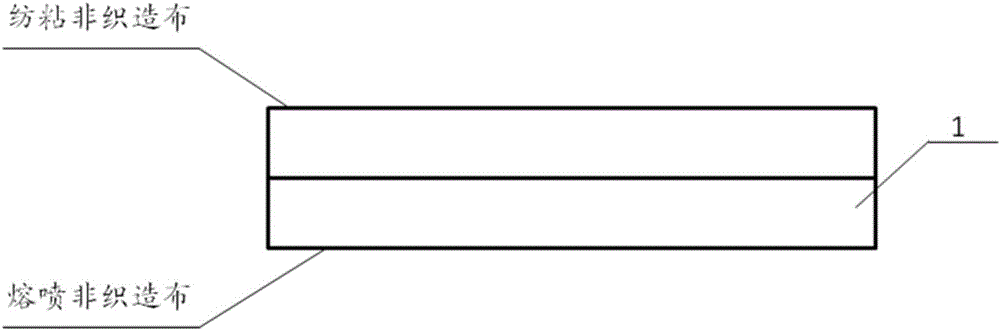

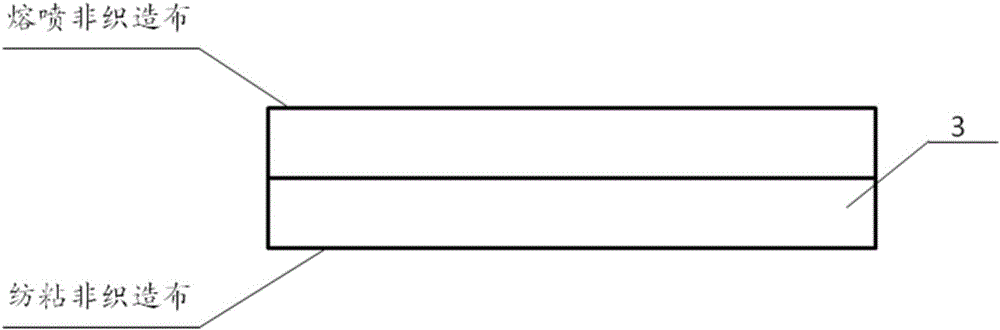

[0030] (1) Fiber web preparation: spunbond non-woven fabric and meltblown non-woven fabric are compounded to make surface layer fiber web 1 and inner layer fiber web 3; combing into web and vertical web laying process are used to make honeycomb cotton-like middle layer Web 2. In order to improve the production efficiency and the quality of the fiber web, the spunbond nonwoven fabric and the meltblown nonwoven fabric are compounded by in-line compounding. In a multi-die production line, one die prepares the spunbond nonwoven, and the other The head prepares a meltblown nonwoven, and the meltblown nonwoven is directly superimposed on the spunbond nonwoven. The surface layer fiber web 1 and the inner layer fiber web 3 are made of spunbond nonwoven fabric and meltblown nonwoven fabric. The fiber web layer is separated, which...

Embodiment

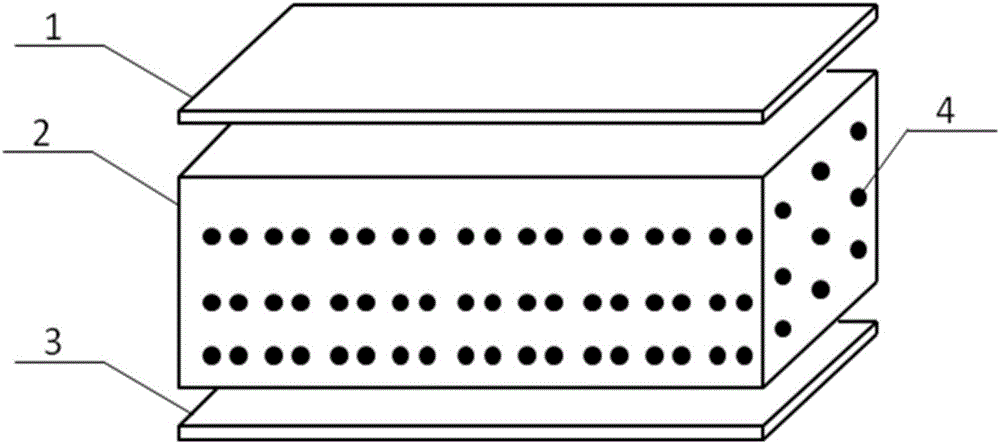

[0037] see Figure 1 to Figure 4 , an antibacterial and anti-mite function filled non-woven fabric, which is composed of a surface layer fiber net 1, a middle layer fiber net 2, and an inner layer fiber net 3, and the inner layer of the middle layer fiber net 2 is sprayed with antibacterial and anti-mite microcapsules 4. The surface layer fiber net 1. The inner layer fiber web 3 is a fiber web composed of a spunbond nonwoven fabric and a meltblown nonwoven fabric, and one side of the meltblown nonwoven fabric is superimposed with the middle layer fiber web 2.

[0038] A preparation method of the above-mentioned antibacterial and anti-mite function filled non-woven fabric, the method comprises the following steps:

[0039] (1) Fiber web preparation: spunbond non-woven fabric and meltblown non-woven fabric are compounded to make surface layer fiber web 1 and inner layer fiber web 3; combing into web and vertical web laying process are used to make honeycomb cotton-like middle la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com