Full-width mercerizing machine for knitting

A mercerizing machine and open-width technology, which is used in the mercerizing of indefinite length fabrics, textile processing machine accessories, textiles and papermaking, etc., can solve the problems of volatile liquid entering the air, unadjustable tension, poor product quality, etc., to reduce labor The effect of finishing workload, good cleaning effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

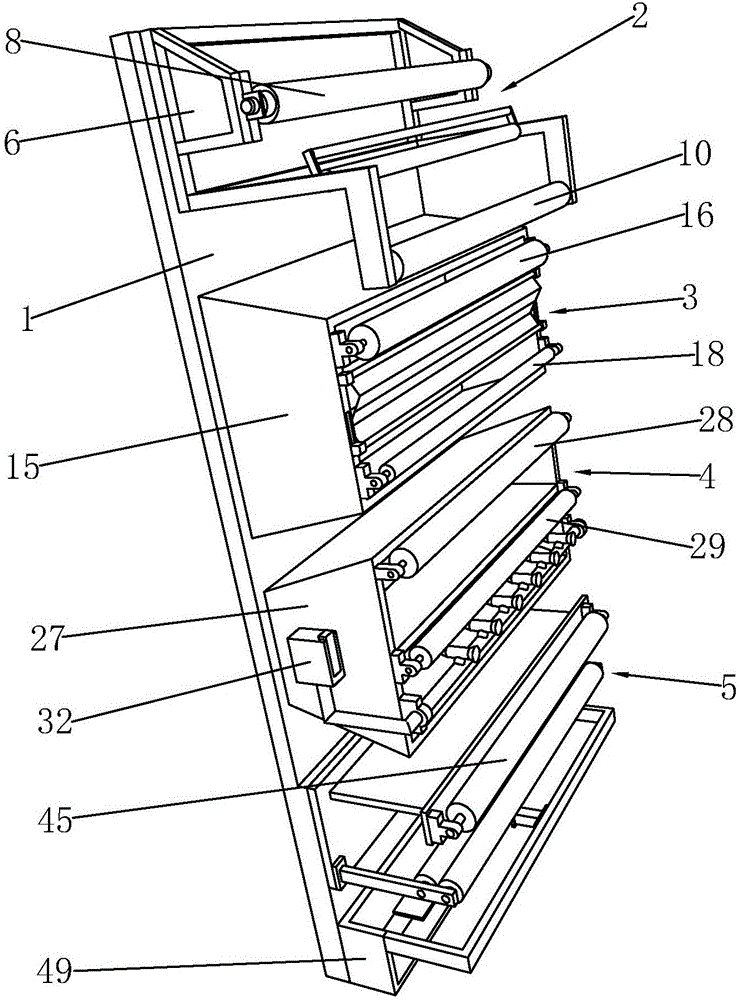

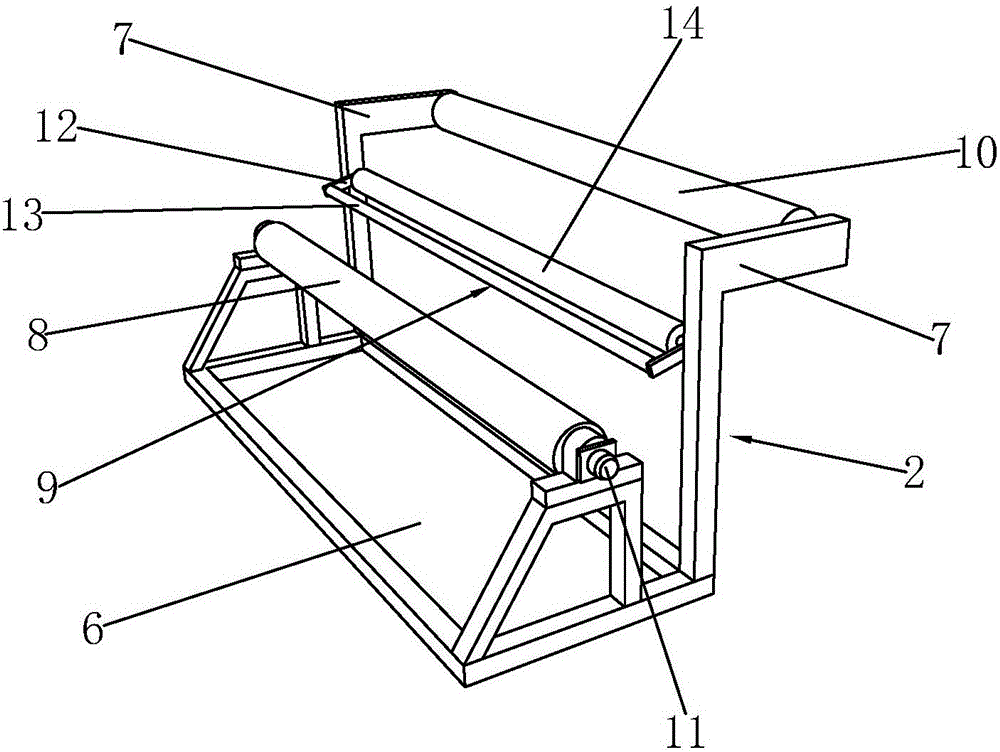

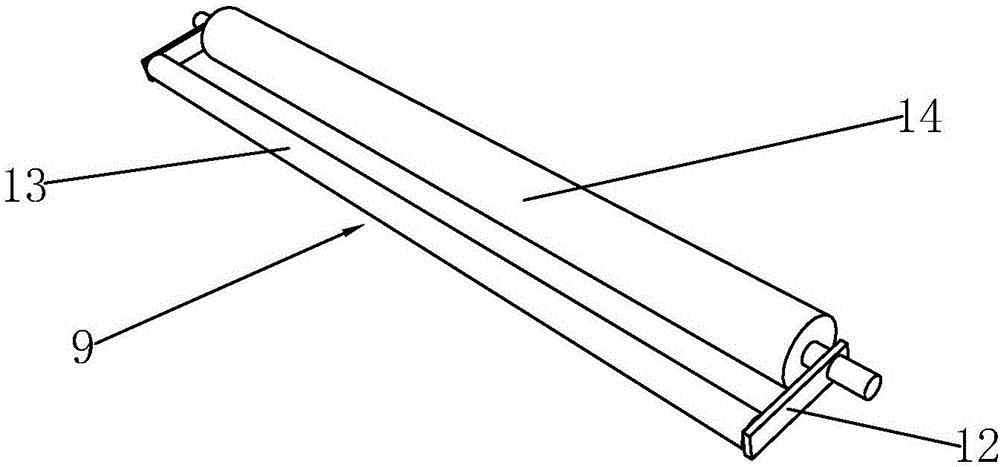

[0030] Such as Figure 1 to Figure 9As shown, it is a knitting open-width mercerizing machine of the present invention, including a support base plate 1, a cloth feeding mechanism 2, an alkali soaking mechanism 3, a washing mechanism 4, and a cloth dropping mechanism 5, a cloth feeding mechanism 2, an alkali soaking mechanism 3, and a washing mechanism 4 and the cloth dropping mechanism 5 are respectively arranged on the support base plate 1, the alkali soaking mechanism 3 is located between the cloth feeding mechanism 2 and the washing mechanism 4, the washing mechanism 4 is located between the alkali soaking mechanism 3 and the cloth dropping mechanism 5, and the cloth feeding mechanism 2 It includes a support platform 6, a support frame 7, a cloth feed roller 8, a tension adjustment assembly 9, and a transmission roller 10. The tension adjustment assembly 9 and the transmission roller 10 are respectively arranged between the support frames 7, and the support frame 7 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com