honeycomb structure block wall

A honeycomb structure and block technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of increasing investment in special-shaped block production equipment, complicated procedures, time-consuming and laborious, and complicated distribution of construction sites, etc., to achieve mechanized operations, The connection is firm and reliable, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

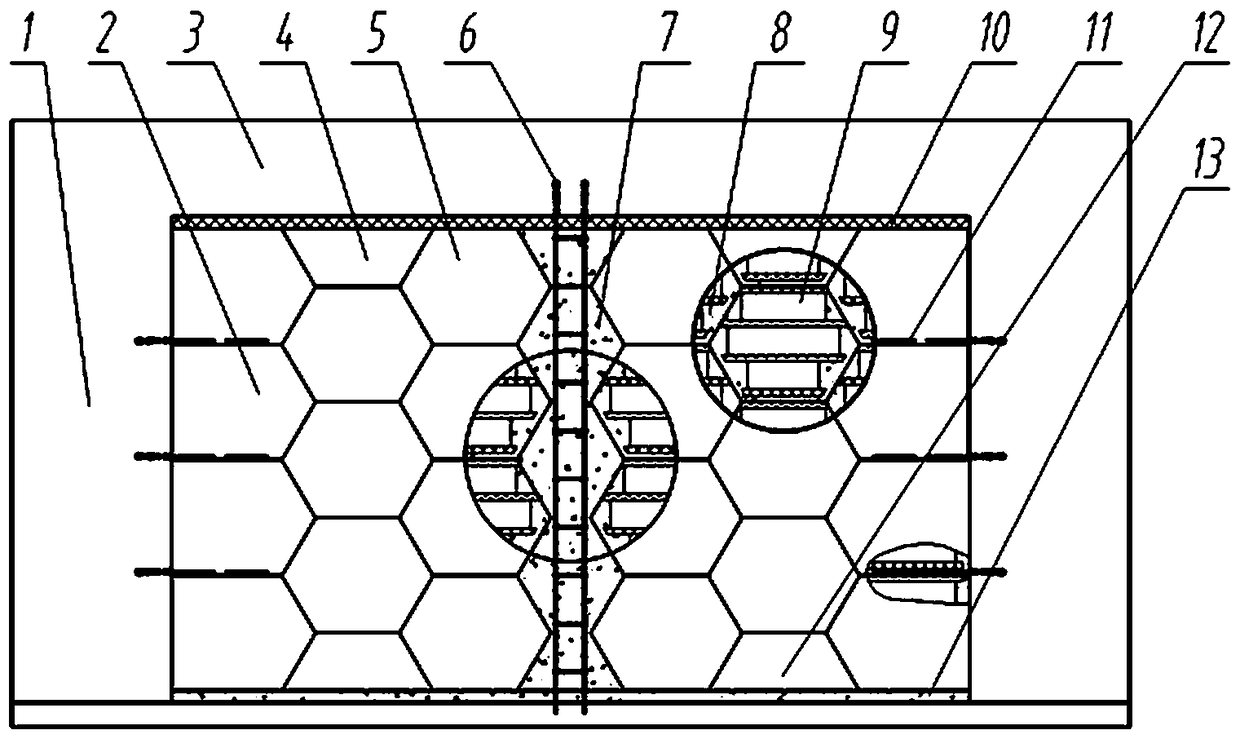

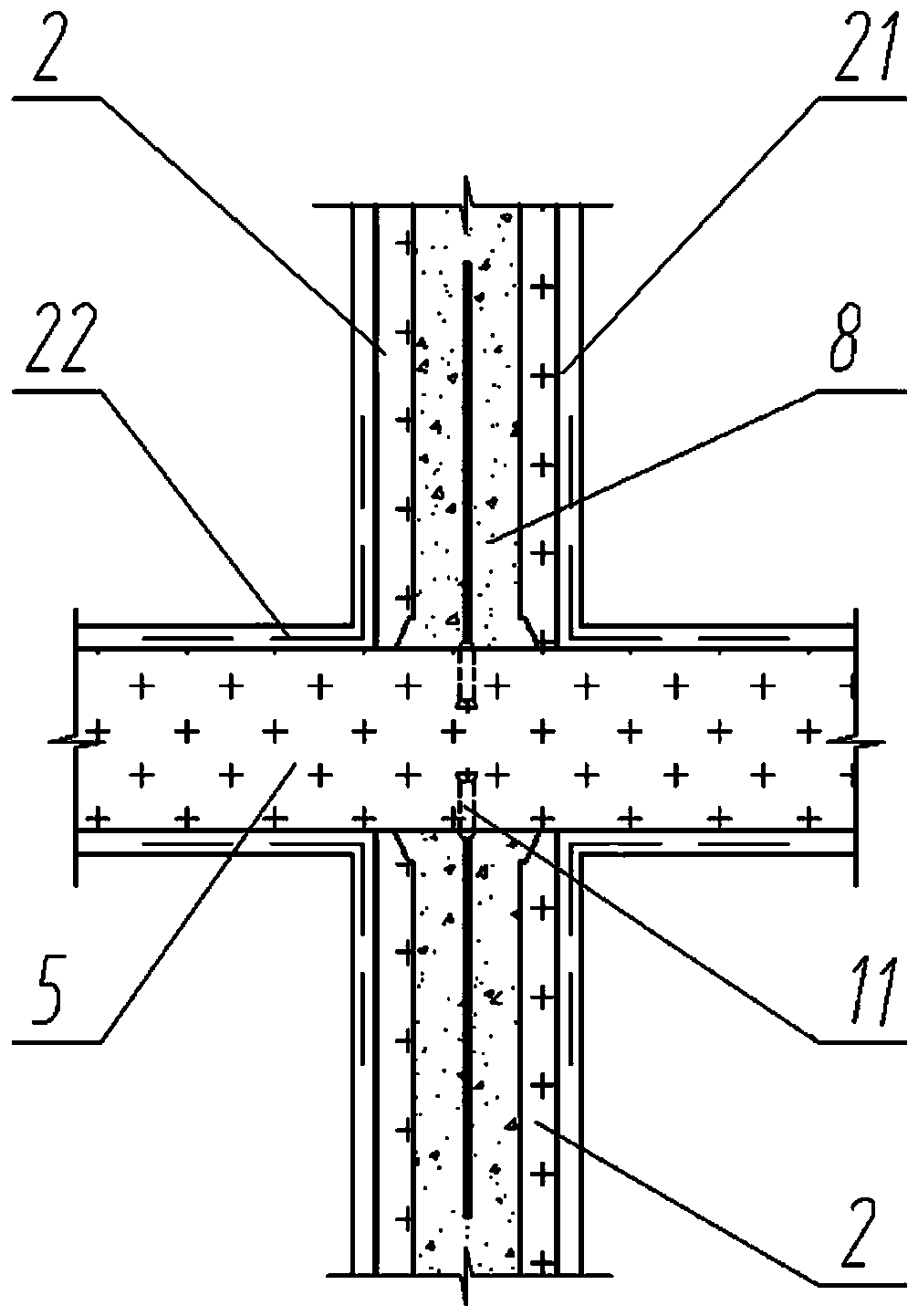

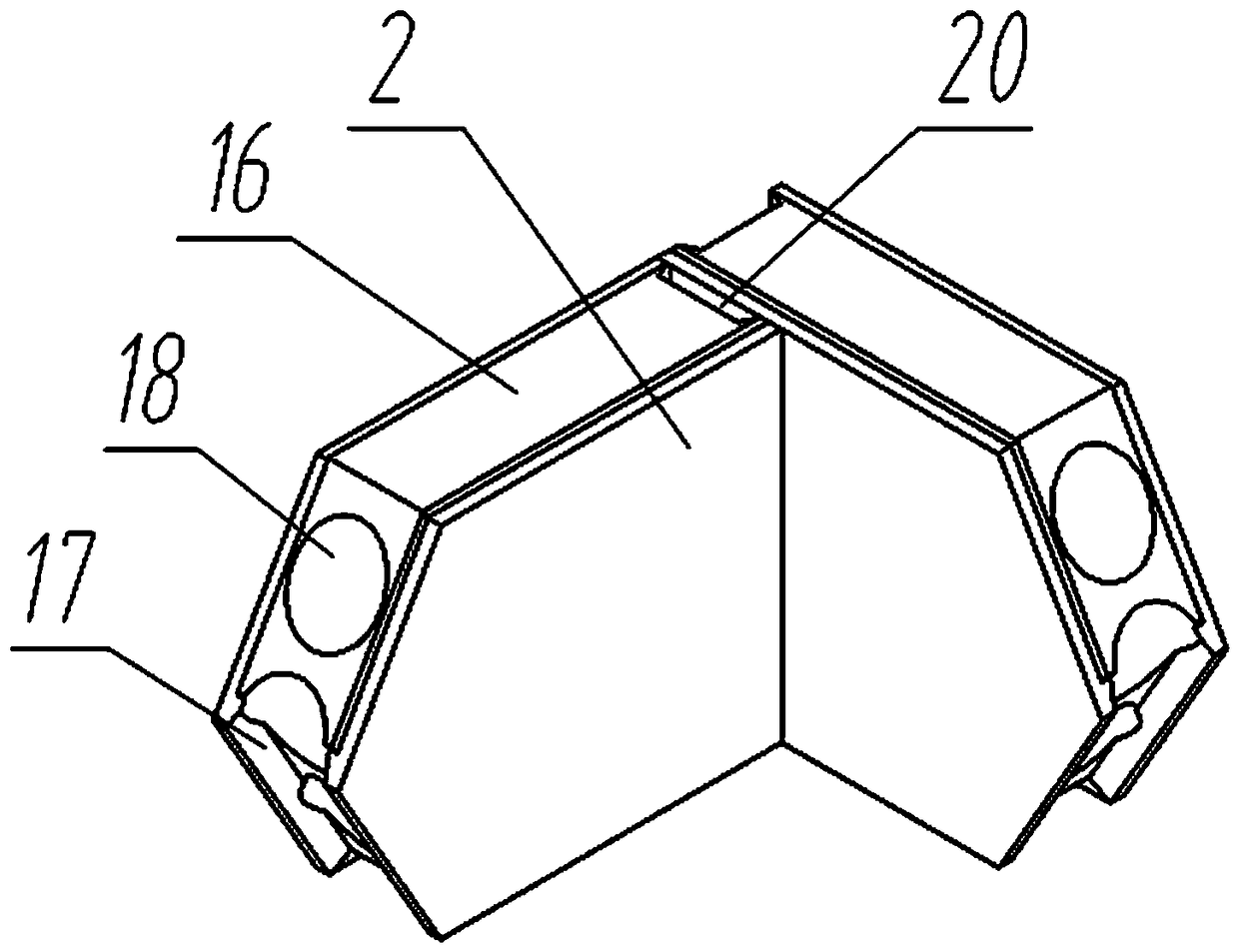

[0047] The honeycomb structure block wall in this example is a hollow plane wall, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 9 , Figure 11 , Figure 13 and Figure 23 As shown, the main body of the wall is formed by connecting hexagonal blocks 5, and the vertical two sides of the wall are formed by connecting pentagonal blocks 2; the middle part of the wall is a pouring belt 7, and reinforcing ribs 6 are arranged in the pouring belt 7; The bottom of the body is composed of a self-leveling cushion layer 13, which is filled up by the lower trapezoidal block 12; the upper side of the wall is a foam board 10, which is filled up by the upper trapezoidal block 4; the hexagonal block 5 and the five sides A through hole 18 is provided in the hexagonal block 2, and the air bag 9 is filled in the through hole 18; tenons 16 are provided on the three sides of the upper half of the hexagonal block 5, and tenon grooves 17 are provided on the three side...

Embodiment 2

[0051] The honeycomb structure block wall in this example is a hollow wall, such as Figure 6 , Figure 10 ,and Figure 14 Shown, except that through hole 18 two ends are provided with plug 19, except that anticorrosion wooden wedge 24 is arranged on the body of wall, all the other are with embodiment one.

Embodiment 3

[0053] The honeycomb structure block wall in this example is a solid wall, such as Figure 5 , Figure 8 , Figure 12 , Figure 21 and Figure 22 As shown, the grouting material 8 is filled in the through hole 18, the vertical side of the pentagonal block 2 is connected with the wall or column 1, and the rib 11 is pre-planted inside the wall, and one end of the rib 11 is connected with the wall or column 1, and the other end Connect with the through hole 18 of the pentagonal block 2 horizontal direction, the upper side of the body of wall is the anticorrosion wooden wedge 24, all the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com