Automatic charging device and intelligent door lock including automatic charging device

A technology of automatic charging device and smart door lock, applied in circuit devices, battery circuit devices, components of connecting devices, etc., can solve problems such as restricting the rapid development of smart door locks, etc. Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

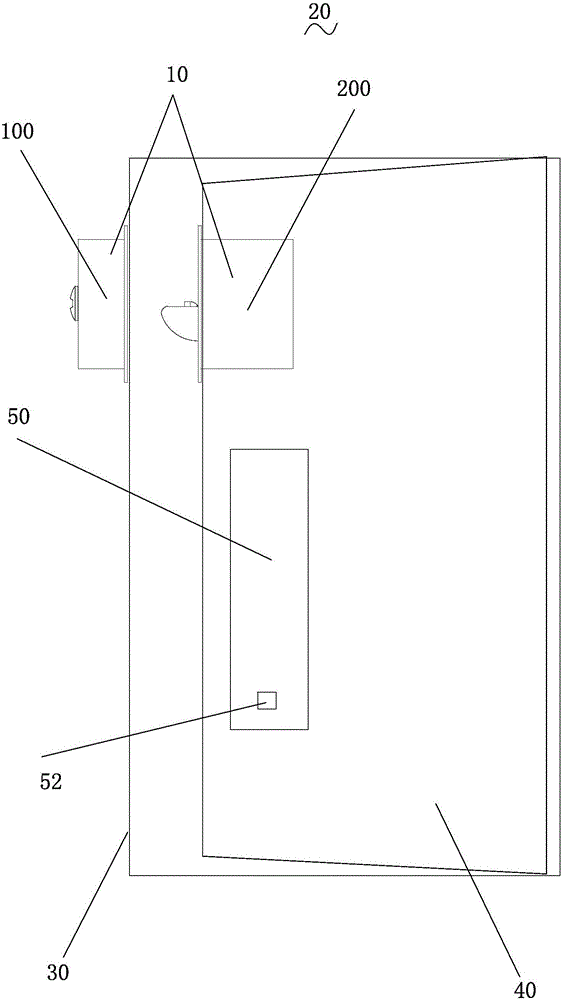

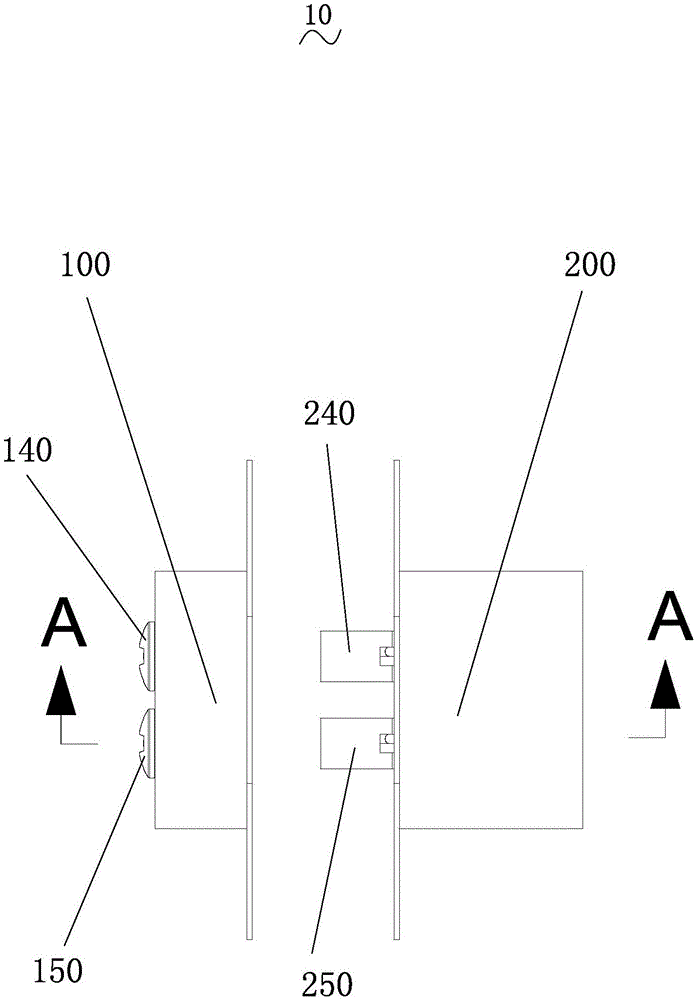

[0036] like figure 2 As shown, an automatic charging device 10 includes a power transmission part 100 and a power receiving part 200;

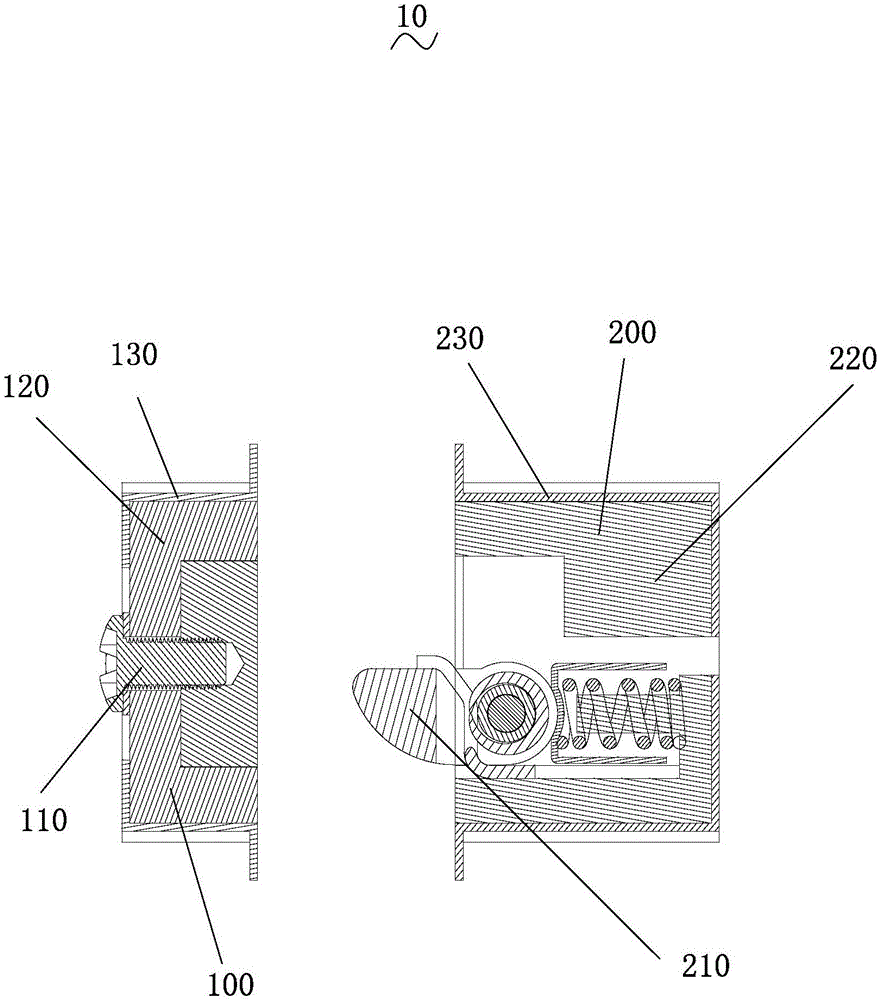

[0037] Please combine figure 2 , image 3 As shown, the power transmission unit 100 includes a power transmission group 110, a first insulating positioning block 120, and a first fixing frame 130 arranged in sequence. The power transmission group 110 includes a positive transmission group 140 and a negative transmission group 150. Please refer to Figure 4 The first insulating positioning block 120 is provided with two mutually independent first grooves 122 and second grooves 124 with an incomplete opening at the bottom, and the first fixing frame 130 is provided with a third groove 132 with an incomplete opening at the bottom , the first insulating positioning block 120 is accommodated in the third groove 132, the positive electrode transmission group 140 and the negative electrode transmission group 150 are respectively accommodated in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com