Actuator having planetary roller screw

A technology of planetary roller and thread transmission, which is applied in the field of clutches to achieve the effect of high load capacity, reduced manufacturing and installation costs, and small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

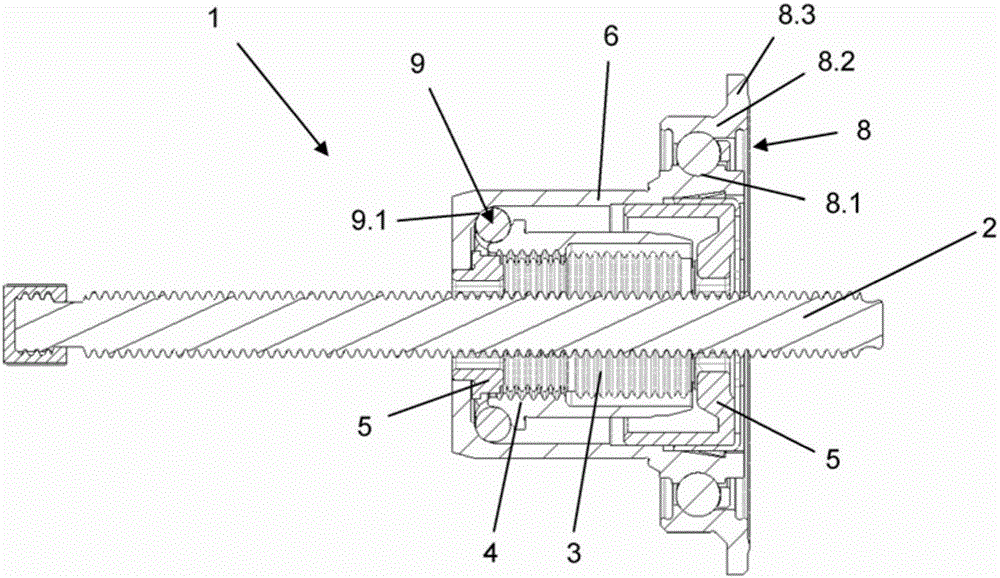

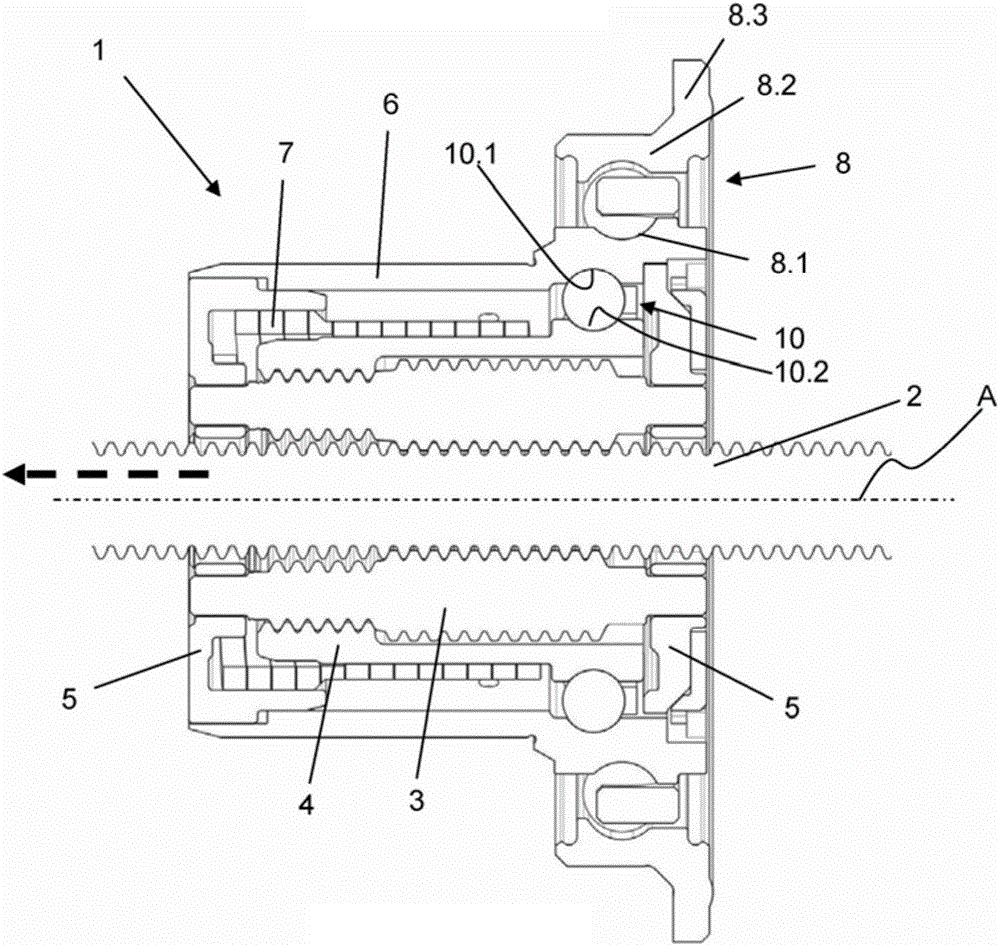

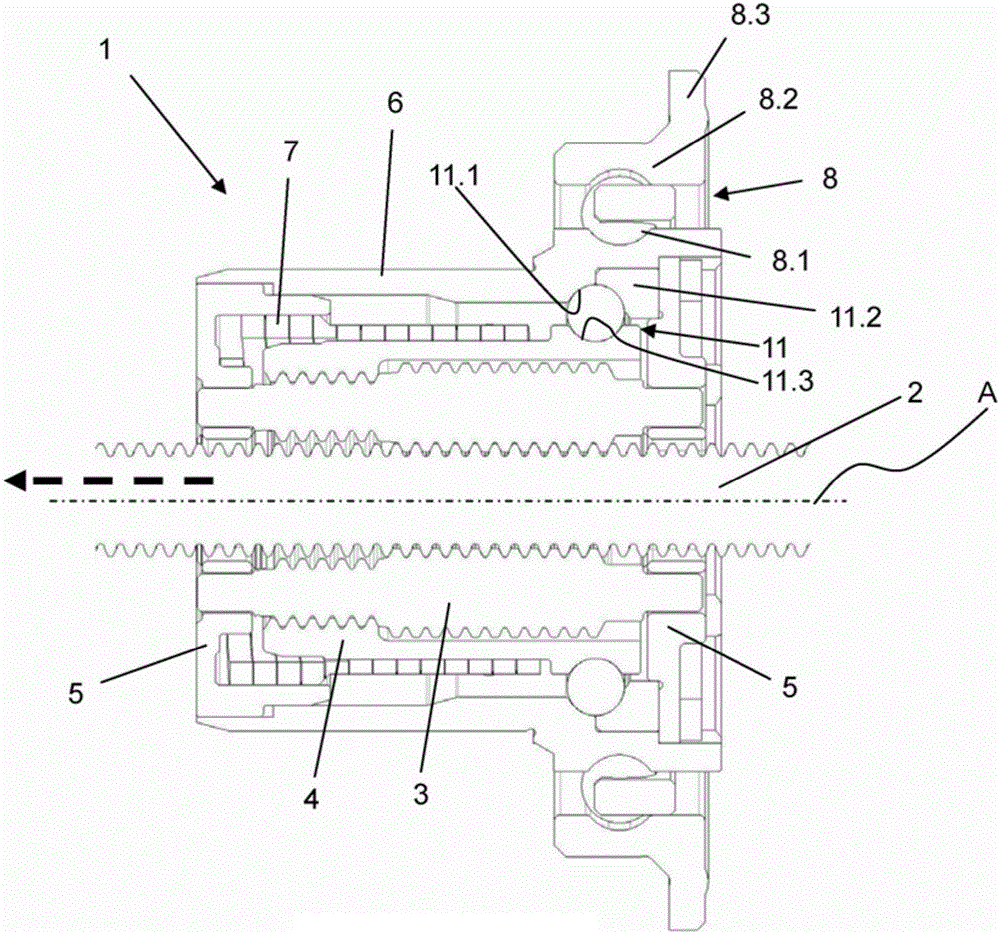

[0024] figure 1 A longitudinal section through a planetary roller screw drive according to the prior art is shown. The screw 2 is engaged by a plurality of planetary rollers 3 which mesh with a ring gear 4 surrounding the planetary rollers. The planetary rollers 3 are positioned at both ends in a planetary roller carrier 5 , which is mounted in a rotationally fixed manner in a sleeve 6 surrounding the ring gear 4 . The sleeve 6 and the planetary roller carrier 5 supported therein are fixed axially and are connected in a rotationally fixed manner via the sleeve 6 to a rotor (not shown) of the drive. The sleeve 6 is rotatably mounted via the main bearing 8 , wherein a bearing raceway 8 . 1 for the interior of the main bearing 8 is contained in the sleeve 6 . The bearing outer ring 8.2 of the main bearing 8 has a radially outwardly directed flange 8.3 for axial and rotationally fixed support on a not shown stator-side housing. The axial support of the planetary roller carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com