Replaceable cover plate type energy-dissipation column base construction

A technology of energy-dissipating columns and cover plates, which is applied to building components, infrastructure engineering, protected buildings/shelters, etc., and can solve problems such as difficult maintenance and reinforcement, unsuitable structures to continue to bear loads, and large plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the concrete implementation description of an example of the present invention is as follows:

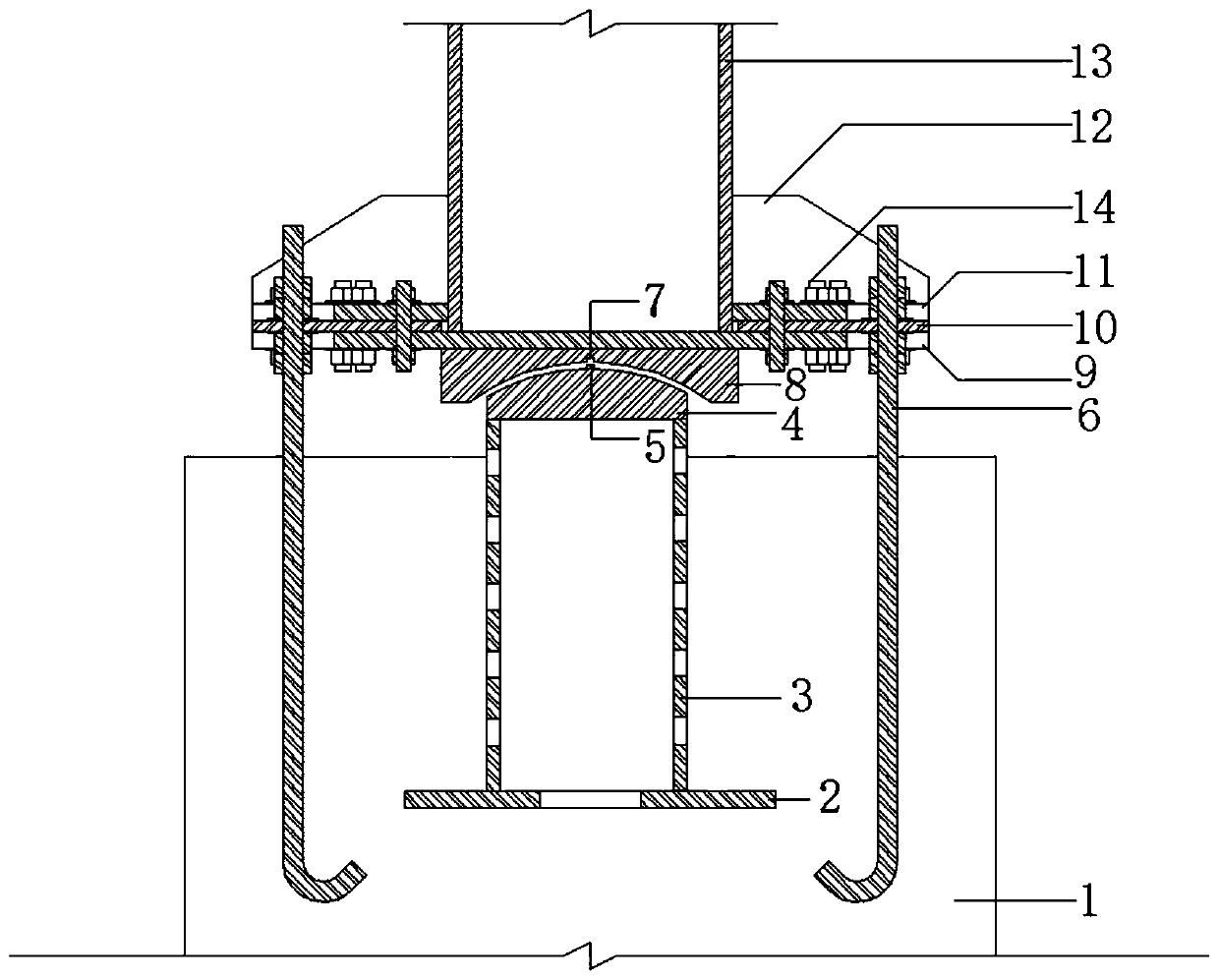

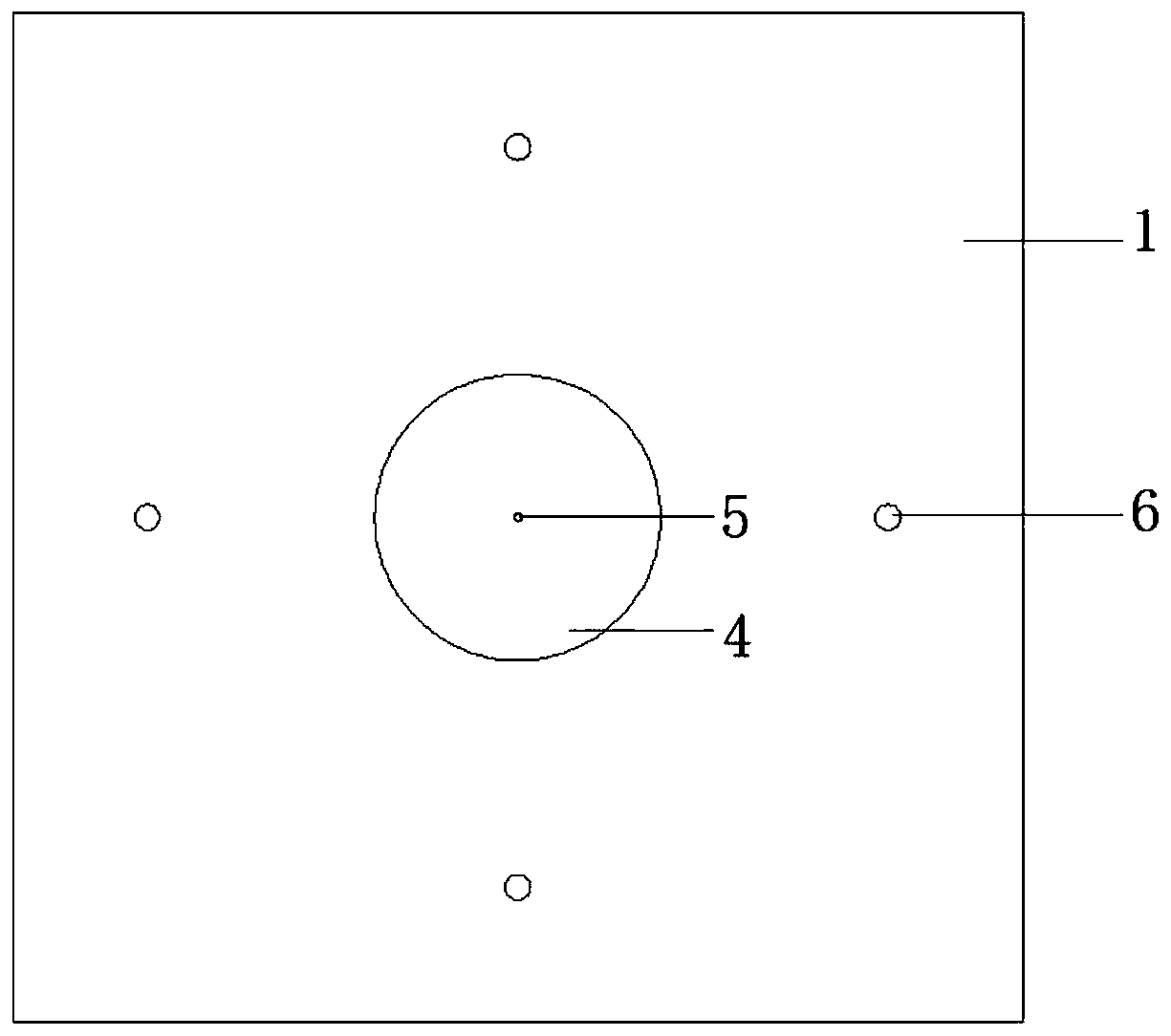

[0030] Such as Figure 7 As shown, first make the foundation embedded parts, and weld the prefabricated steel plate 2 with holes, the steel pipe with holes 3, the spherical casting 4, and the protrusion 5.

[0031] Such as figure 2 , image 3 As shown, the anchor bolt 6 and the foundation embedded parts are installed and fixed before the foundation 1 is poured, the foundation 1 is poured and fully vibrated, and the concrete is poured into the embedded parts.

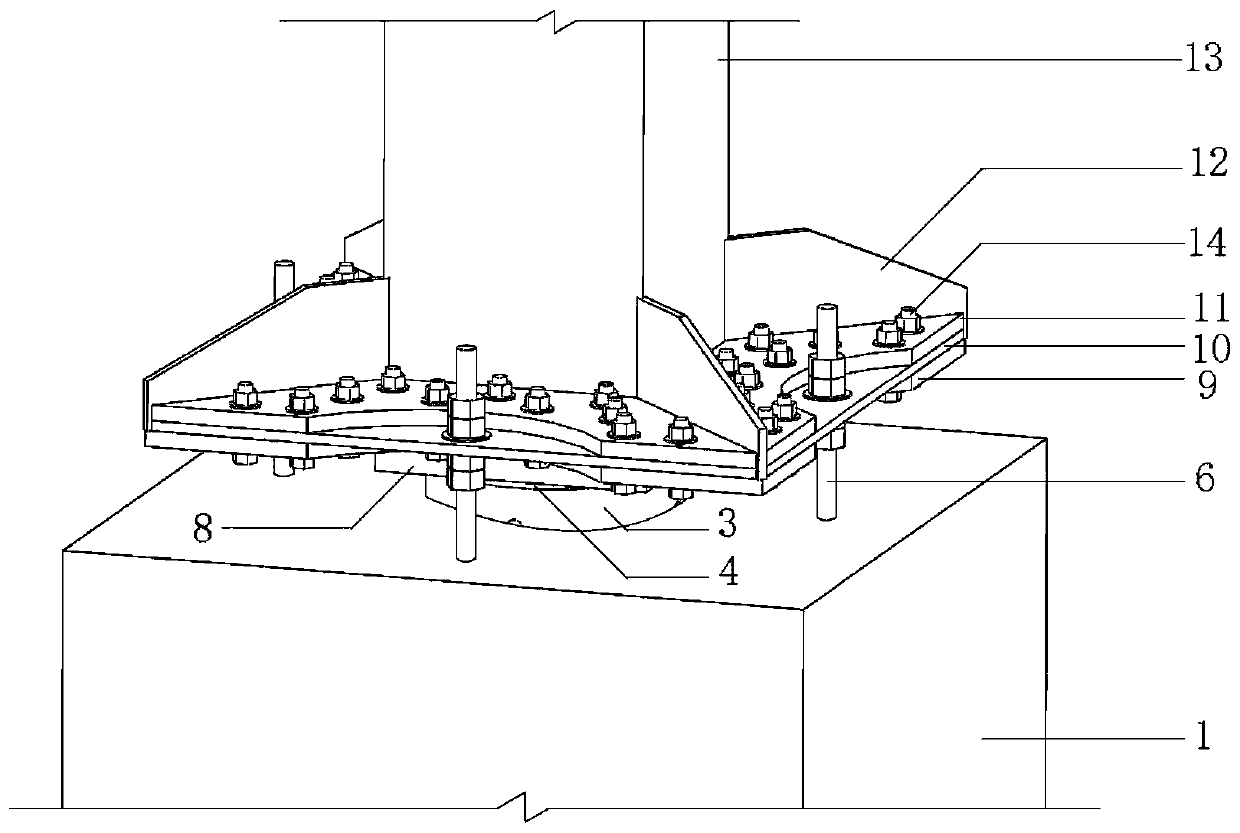

[0032] Such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, after the strength of the foundation 1 reaches 75%, the assembly of the upper part of the column foot is carried out in the following order:

[0033] First weld the factory prefabricated bottom plate 9 to the steel column 13, then weld the stiffeners 12, and then weld the factory pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com