Petroleum pipe fitting

A technology for oil pipes and pipe bodies, which is applied in the directions of pipes/pipe joints/fittings, pipe supports, electrical components, etc., can solve the problems of low wiring efficiency, complicated and complicated operation, built-in wiring structure, etc., and achieves efficient wiring and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing of description, the present invention will be further described.

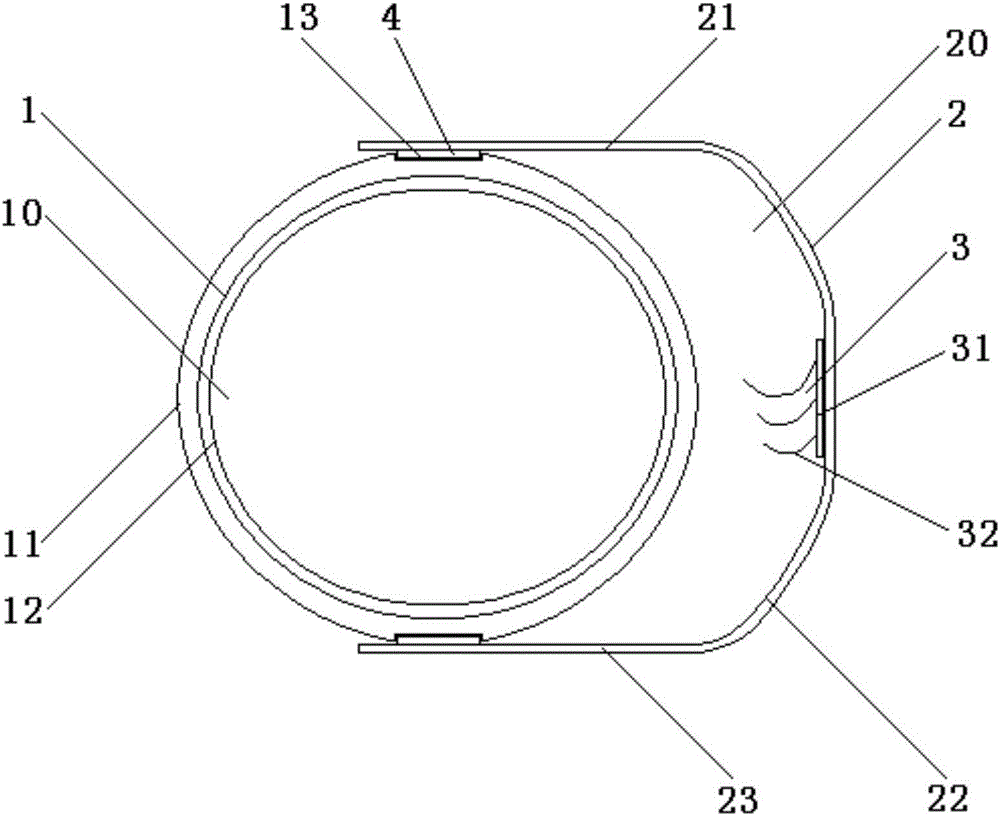

[0018] Such as figure 1 A petroleum pipe fitting shown includes a pipe body 1 and a buckle shell 2. The pipe body 1 has a medium channel 10 for oil circulation. The buckle shell 2 is detachably clamped and covered on the outer wall of the pipe body 1 On the arc, a wiring space 20 is formed between the buckle shell 2 and the outer wall of the tube body 1 .

[0019] The buckle shell 2 is U-shaped, including a first extension plate 21, an intermediate base plate 22, and a second extension plate 23 connected in sequence; The sides are arranged facing each other, and the distance between the first extension plate 21 and the second extension plate 23 is equal to the diameter of the pipe body 1 .

[0020] The intermediate substrate 22 is provided with a wire hook 3 located in the wiring space 20 for hooking the laid cables and stabilizing the cables.

[0021] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com