Inflatable type thin oil sealing gas tank

A gas cabinet and inflatable technology, which is applied in the field of gas cabinets, can solve problems such as general sealing effect, side plate deformation, and gas escape, and achieve the effects of reducing installation accuracy requirements, strong strain adjustment ability, and strengthening sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

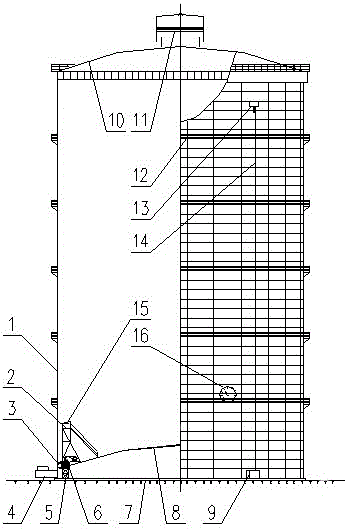

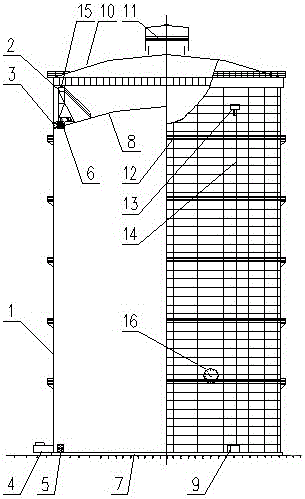

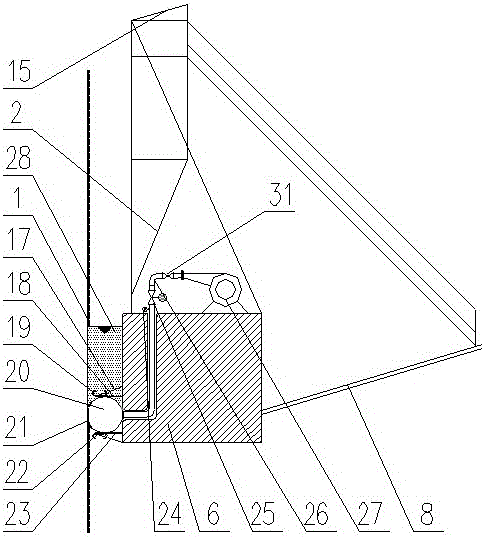

[0032] Such as figure 1 and figure 2 As shown, a general gas cabinet includes a cabinet body and a sealing device 3. The main structure of the cabinet body is surrounded by a bottom plate 7, a top plate 10 and a side plate 1. A piston frame 2 that can be lifted is arranged in the cabinet body, and a piston frame 2 is provided at the bottom of the gas cabinet. There are piston ring beams 6 and piston plates 8, a piston backing plate 5 is provided at the bottom of the cabinet, an inlet and outlet pipe 4 is provided at the bottom of the outer wall of the side plate 1, an annular walkway 12 and a cabinet capacity indicator 16 are provided on the outer wall of the side plate 1, and the top plate 10 There is a ventilation building 11 on the top, and the up and down movement of the piston mechanism can realize the entry and exit of gas, and the gas and air a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com