Method and device for improving generating capacity of sintering waste heat utilization clusters

A technology of waste heat power generation and power generation, which is applied in the directions of improving energy efficiency, process efficiency, waste heat treatment, etc. It can solve the problems of unstable power generation efficiency of steam turbines, fluctuation of high-temperature steam steam production, and failure to meet design standards. Increase the power generation from sintering waste heat, reduce environmental pollution, and increase the effect of power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

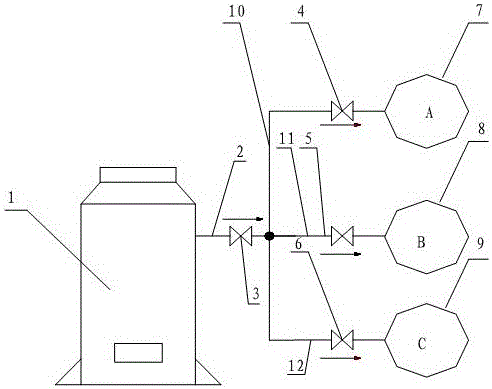

[0010] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The present invention firstly discloses a method for increasing the power generation capacity of sintering waste heat utilization clusters. The method is as follows: more than two sets of sintering waste heat utilization clusters are connected in parallel to the output main pipe, and the output main pipe is connected to the gas boiler. When any one of the sintering waste heat utilization clusters When the sintering waste heat boiler frequently disassembles due to the shutdown of the sintering system, the gas-fired tube boiler sends steam to the sintering waste heat utilization cluster through the output main pipe. , through the combustion of excess coke oven gas, it not only reduces the environmental pollution that may be caused by excessive discharge of coke oven gas, but also when an abnormal phenomenon occurs in any set of sintering waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com